Porous membrane for secondary battery, separator for secondary battery, and secondary battery

A technology for secondary batteries and porous membranes, applied in secondary batteries, battery pack components, circuits, etc., can solve the problems of expansion of short-circuit parts, easy shrinkage, generation of reaction heat, etc., and achieves high adhesion strength and is not easy to curl. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

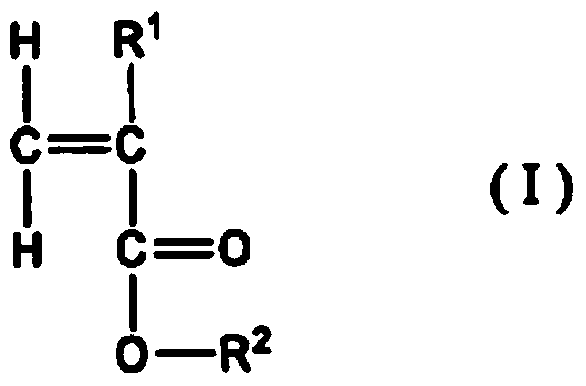

Method used

Image

Examples

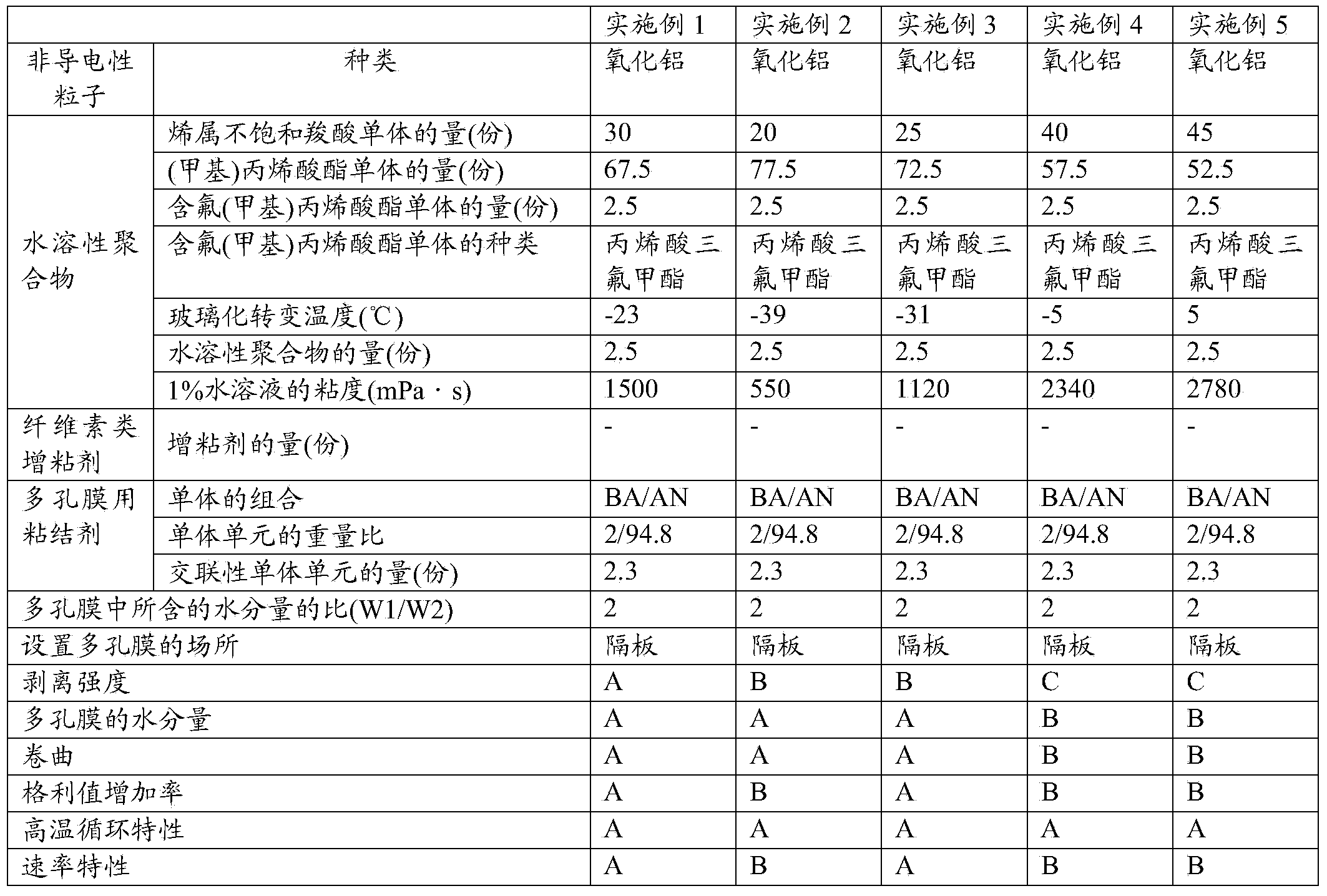

Embodiment 1

[0272] (manufacturing of water-soluble polymers)

[0273] Add 67.5 parts of ethyl acrylate as (meth)acrylate monomer, 30 parts of methacrylic acid as ethylenically unsaturated carboxylic acid monomer, 2.5 parts of trifluoromethyl methacrylate as an ester monomer, 1.0 parts of sodium dodecylbenzenesulfonate as an emulsifier, 150 parts of ion-exchanged water, and 0.5 parts of potassium persulfate as a polymerization initiator, and fully stirred , heated to 60 ° C to initiate polymerization. When the polymerization conversion rate reached 96%, the reaction was cooled to stop the reaction, and an aqueous solution containing a water-soluble polymer was obtained. 10% ammonia water was added to the aqueous solution containing the water-soluble polymer thus obtained to adjust the pH to 8 to obtain an aqueous solution containing the desired water-soluble polymer. When the weight average molecular weight of the obtained water-soluble polymer was measured, it was 128,000.

[0274] Usi...

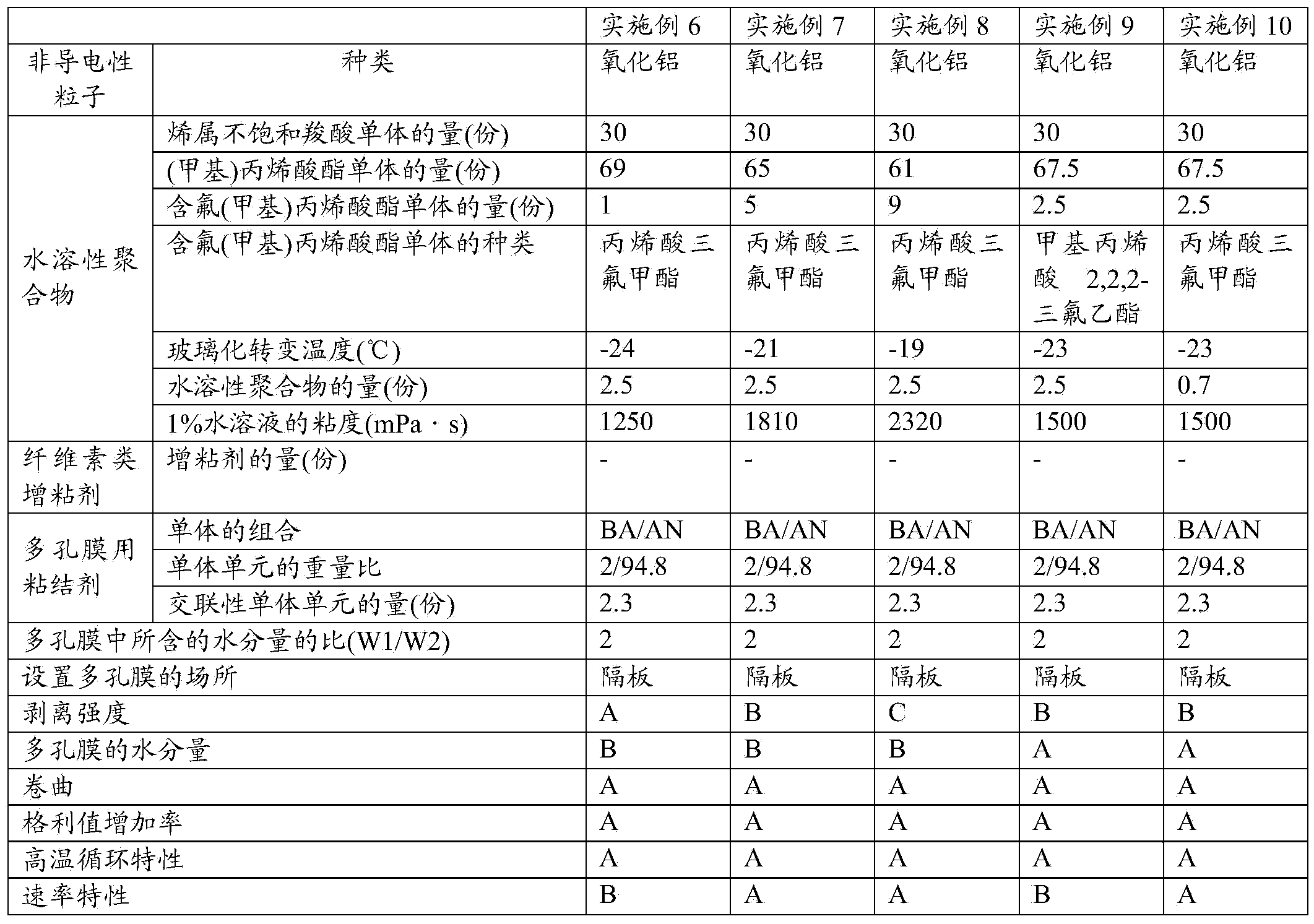

Embodiment 2

[0290] When producing the water-soluble polymer, the amount of ethyl acrylate as the (meth)acrylate monomer was changed to 77.5 parts, and the amount of methacrylic acid as the ethylenically unsaturated carboxylic acid monomer was changed to 20 parts, Other than that, it carried out similarly to Example 1, the water-soluble polymer, separator, and battery were manufactured, and each evaluated. The results are shown in Table 1.

Embodiment 3

[0292] When producing the water-soluble polymer, the amount of ethyl acrylate as a (meth)acrylate monomer was changed to 72.5 parts, and the amount of methacrylic acid as an ethylenically unsaturated carboxylic acid monomer was changed to 25 parts, Other than that, it carried out similarly to Example 1, the water-soluble polymer, separator, and battery were manufactured, and each evaluated. The results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com