Method for extracting herbaceous plants for external application by using small molecule cutting technology

A technology of herbal plants and cutting technology, which is applied in the field of small molecule cutting technology to extract herbal plants for external use, which can solve the problems of slow curative effect, limited development of Chinese herbal medicine, and complicated methods of use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

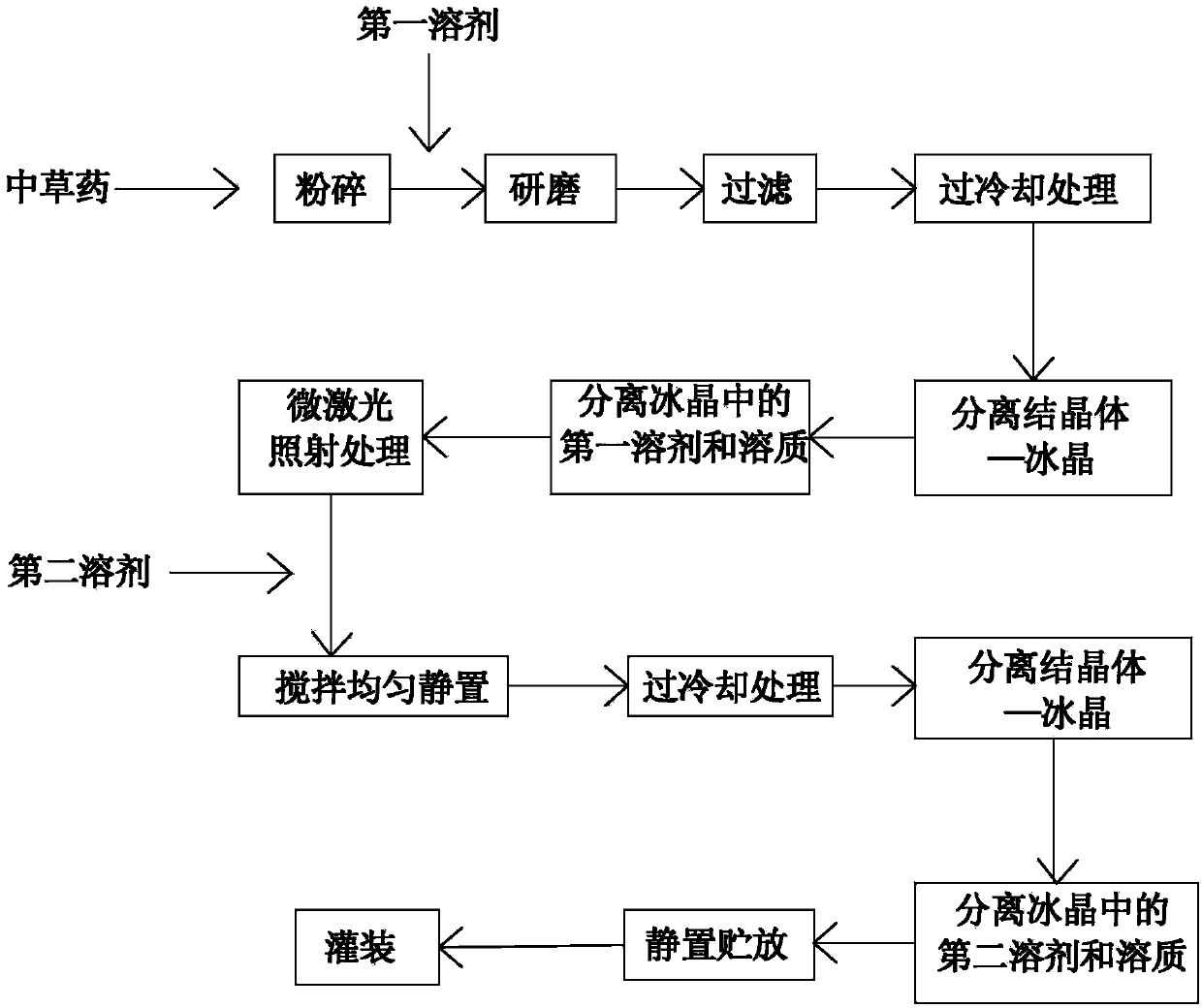

Image

Examples

Embodiment 1

[0026] a. Take 500 g of Bupleurum bupleuri for removing mildew and impurities, pulverize it and dissolve it in 5L of ethanol solution, place it in an ultrasonic grinding device and grind for 4 minutes, then filter the ground slurry to recover the filtrate;

[0027] b. Cool the recovered filtrate to below -12°C to make ice crystals form in the filtrate, then separate the generated ice crystals, use a centrifugal pump to separate the solute and ethanol in the ice crystals, and place the separated solute under a micro-laser Perform irradiation treatment; the wavelength of the micro-laser is 100-1000 nanometers, and the pulse width is 1-30 nanoseconds;

[0028] c. Dissolve the irradiated solute in 100ml ethanol to form a solution, stir the solution evenly and let it stand for 10 minutes, then cool the solution down to below -12°C to make ice crystals form in the filtrate, and then dissolve the solution The ice crystals are separated, and the solute and ethanol in the ice crystals ...

Embodiment 2

[0030] a. Take 500 g of Atractylodes atractylodis for removing mildew and impurities, pulverize it and dissolve it in 2L of acetone solution, place it in an ultrasonic grinding device and grind it for 10 minutes, then filter the ground slurry to recover the filtrate;

[0031] b. Cool the recovered filtrate to below -13°C to make ice crystals form in the filtrate, then separate the generated ice crystals, use a centrifugal pump to separate the solute and ethanol in the ice crystals, and place the separated solute under a micro-laser Perform irradiation treatment; the wavelength of the micro-laser is 100-1000 nanometers, and the pulse width is 1-30 nanoseconds;

[0032] c. Dissolve the irradiated solute in 150ml acetone to form a solution, stir the solution evenly and let it stand for 8 minutes, then cool the solution down to below -12°C to make ice crystals form in the filtrate, and then dissolve the solution The ice crystals are separated, and the solute and ethanol in the ice...

Embodiment 3

[0034] a. Get 500g of pinellia radix that removes mildew and impurities, dissolve it in 3L of carbon tetrachloride solution after being pulverized, place it in an ultrasonic grinding device and grind for 8min, then filter the ground slurry to reclaim the filtrate;

[0035] b. Cool the recovered filtrate to below -12°C to make ice crystals form in the filtrate, then separate the generated ice crystals, use a centrifugal pump to separate the solute and ethanol in the ice crystals, and place the separated solute under a micro-laser Perform irradiation treatment; the wavelength of the micro-laser is 100-1000 nanometers, and the pulse width is 1-30 nanoseconds;

[0036] c. Dissolve the irradiated solute in 100ml carbon tetrachloride to form a solution, stir the solution evenly and let it stand for 12 minutes, then cool the solution down to below -12°C so that ice crystals are formed in the filtrate, and then Then the generated ice crystals are separated, and the solute and ethanol ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com