Preparation of Acrylic Acid/Polyvinylpyrrolidone/Palygorskite Composite Adsorbent Material

A technology of polyvinylpyrrolidone and composite adsorption materials, which is applied in the direction of adsorption of water/sewage treatment, alkali metal compounds, alkali metal oxides/hydroxides, etc., and can solve water environmental pollution, high toxicity, biodegradation and decolorization difficulties, etc. problems, to achieve the effect of improving the adsorption performance and increasing the interstitial aggregation of molecules

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

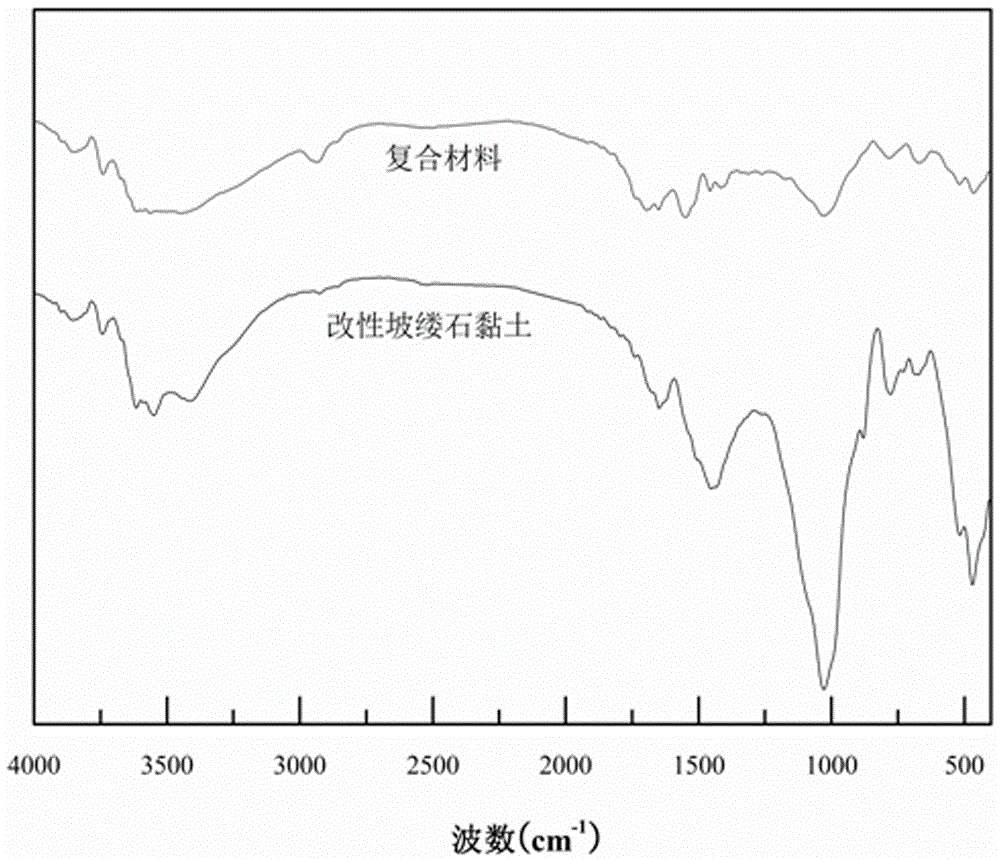

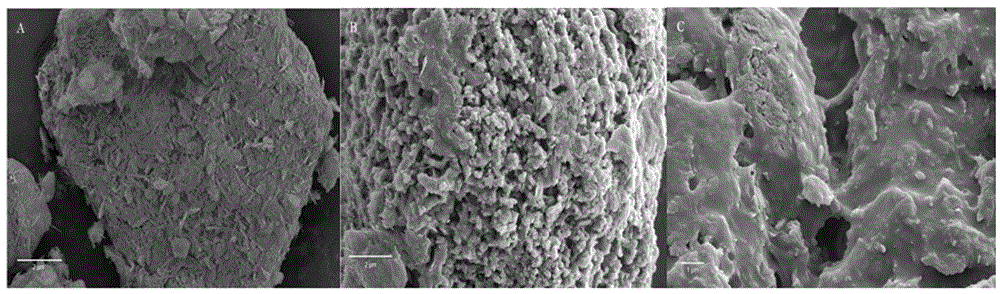

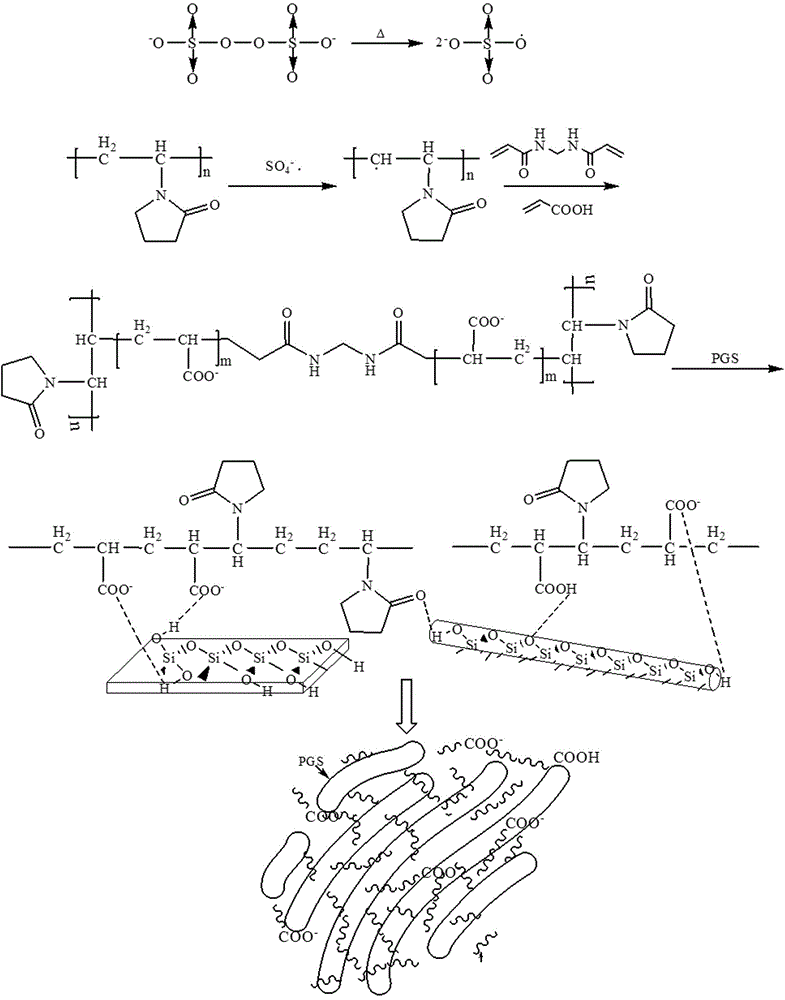

[0026] (1) Modification of palygorskite clay: Take 161g of palygorskite clay raw ore and add it to a 1000 mL beaker, add water to 600mL, stir mechanically (1000 rpm) for 8h, dilute the suspension with water, and pour the upper layer after standing for a period of time For the clear liquid and the bottom sand layer, wash the mud suspension in the middle layer three times, dry, crush, acidify and wash with 1 M hydrochloric acid to neutrality, then dry and crush, and pass through a 200-mesh sieve to obtain acidified modified palysine Stone clay (PGS), spare.

[0027] (2) Preparation of acrylic acid / polyvinylpyrrolidone / palygorskite clay composite adsorption material: Weigh 7.2g of AA and 20mL of distilled water into a three-necked flask, stir mechanically at room temperature for half an hour, then add 1.6 Adjust the neutralization degree to 40% with gNaOH, and stir for 30 min, add 7.2g of modified PGS, continue to stir for 10 min, then add 7.2g of PVP and 0.72g of MBA, raise the ...

Embodiment 2

[0030] (1) Modification of palygorskite clay: Take 161g of palygorskite clay raw ore and add it to a 1000 mL beaker, add water to 600mL, stir mechanically (1000 rpm) for 8h, dilute the suspension with water, and pour the upper layer after standing for a period of time For the clear liquid and the bottom sand layer, wash the mud suspension in the middle layer three times, dry, crush, acidify and wash with 1 M hydrochloric acid to neutrality, then dry and crush, and pass through a 200-mesh sieve to obtain acidified modified palysine Stone clay (PGS), spare.

[0031] (2) Preparation of acrylic acid / polyvinylpyrrolidone / palygorskite clay composite adsorption material: Weigh 7.2g of AA and 20mL of distilled water into a three-necked flask, stir mechanically at room temperature for half an hour, then add 3.6 Adjust the neutralization degree to 90% with gNaOH, and stir for 30 min, add 36g of modified PGS, continue to stir for 10 min, then add 1.2g of PVP and 0.12g of MBA, raise the t...

Embodiment 3

[0034] (1) Modification of palygorskite clay: Take 161g of palygorskite clay raw ore and add it to a 1000 mL beaker, add water to 600mL, stir mechanically (1000 rpm) for 8h, dilute the suspension with water, and pour the upper layer after standing for a period of time For the clear liquid and the bottom sand layer, wash the mud suspension in the middle layer three times, dry, crush, acidify and wash with 1 M hydrochloric acid to neutrality, then dry and crush, and pass through a 200-mesh sieve to obtain acidified modified palysine Stone clay (PGS), spare.

[0035] (2) Preparation of acrylic acid / polyvinylpyrrolidone / palygorskite clay composite adsorption material: Weigh 7.2g of AA and 20mL of distilled water into a three-necked flask, stir mechanically at room temperature for half an hour, then add 2.4 Adjust the neutralization degree to 60% with gNaOH, and stir for 30 min, add 12.0g of modified PGS, continue to stir for 10 min, then add 2.4g of PVP and 0.36g of MBA, raise the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| clearance rate | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com