Preparation method of C2 selective hydrogenation catalyst

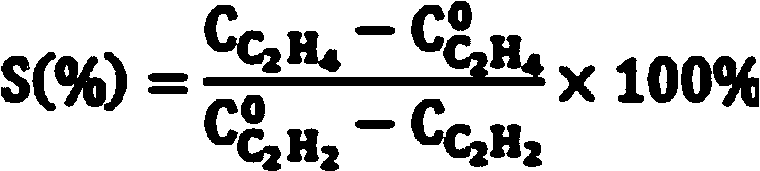

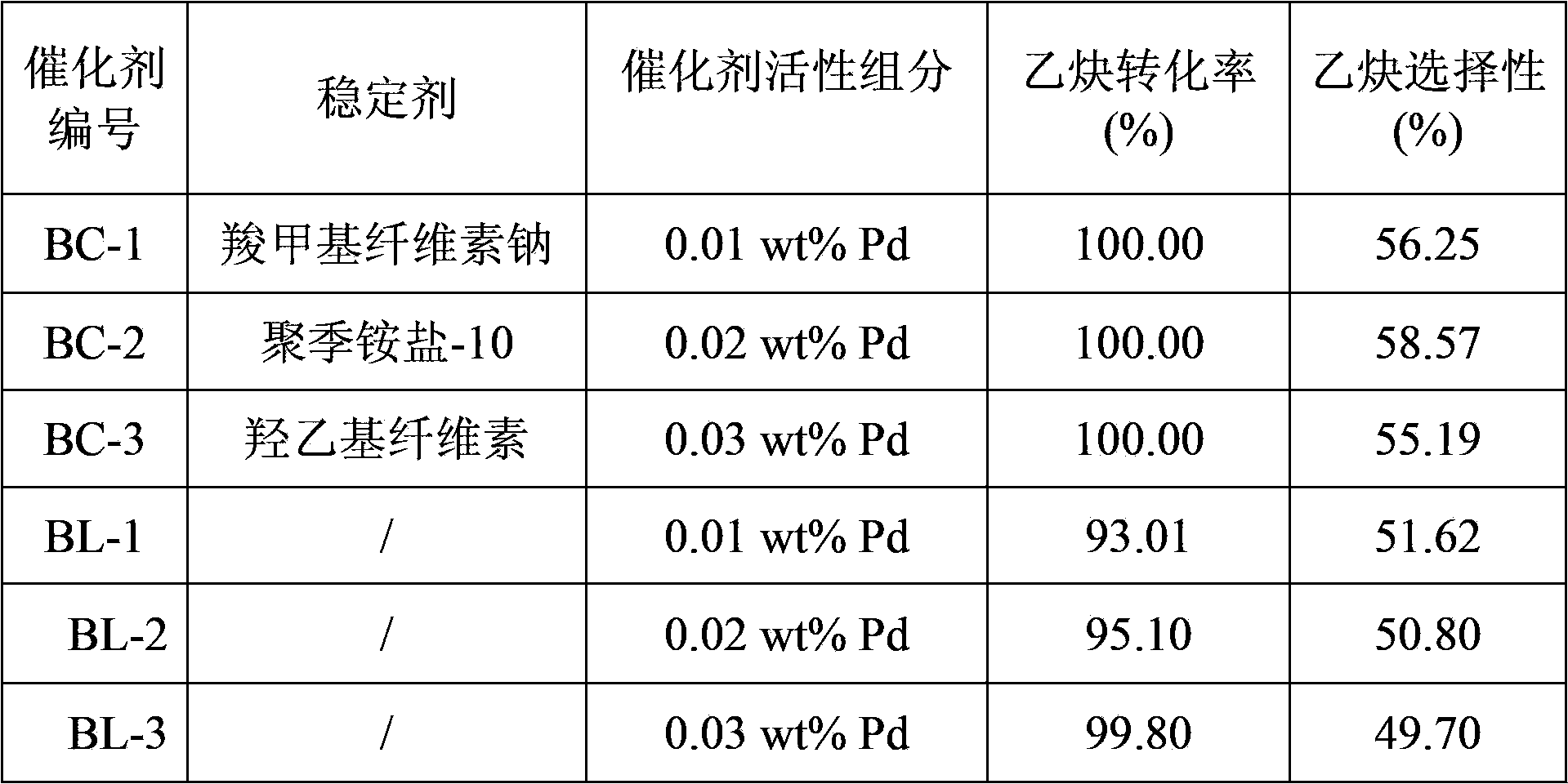

A technology for selective hydrogenation and catalysts, applied in catalyst activation/preparation, hydrocarbons, chemical instruments and methods, etc., can solve the problem of unsatisfactory catalyst activity and selectivity, active component Pd and co-active component content High, catalyst activity and selectivity decline and other problems, to achieve the effect of improving activity and selectivity, enhancing dispersibility and utilization, and narrow particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] ①Pipe 50mgPd / ml of Pd(NO 3 ) 2 2ml solution, diluted to 100g with deionized water solution;

[0031] ②In a constant temperature water bath at 20℃, dissolve 0.1g of anionic stabilizer sodium carboxymethylcellulose in 400g of deionized water, magnetically stir for 2h, then add ① to ②, while adjusting the pH value with sodium hydroxide To neutral, stir for 2 hours to obtain an aqueous solution containing nanoparticles, in which the weight ratio of deionized water, catalyst active components, and stabilizer sodium carboxyv methylcellulose is = 1:0.0002:0.0002;

[0032] ③Weigh the tooth shape Al 2 O 3 Carrier 100g, on which 50g of the above-prepared aqueous solution is impregnated;

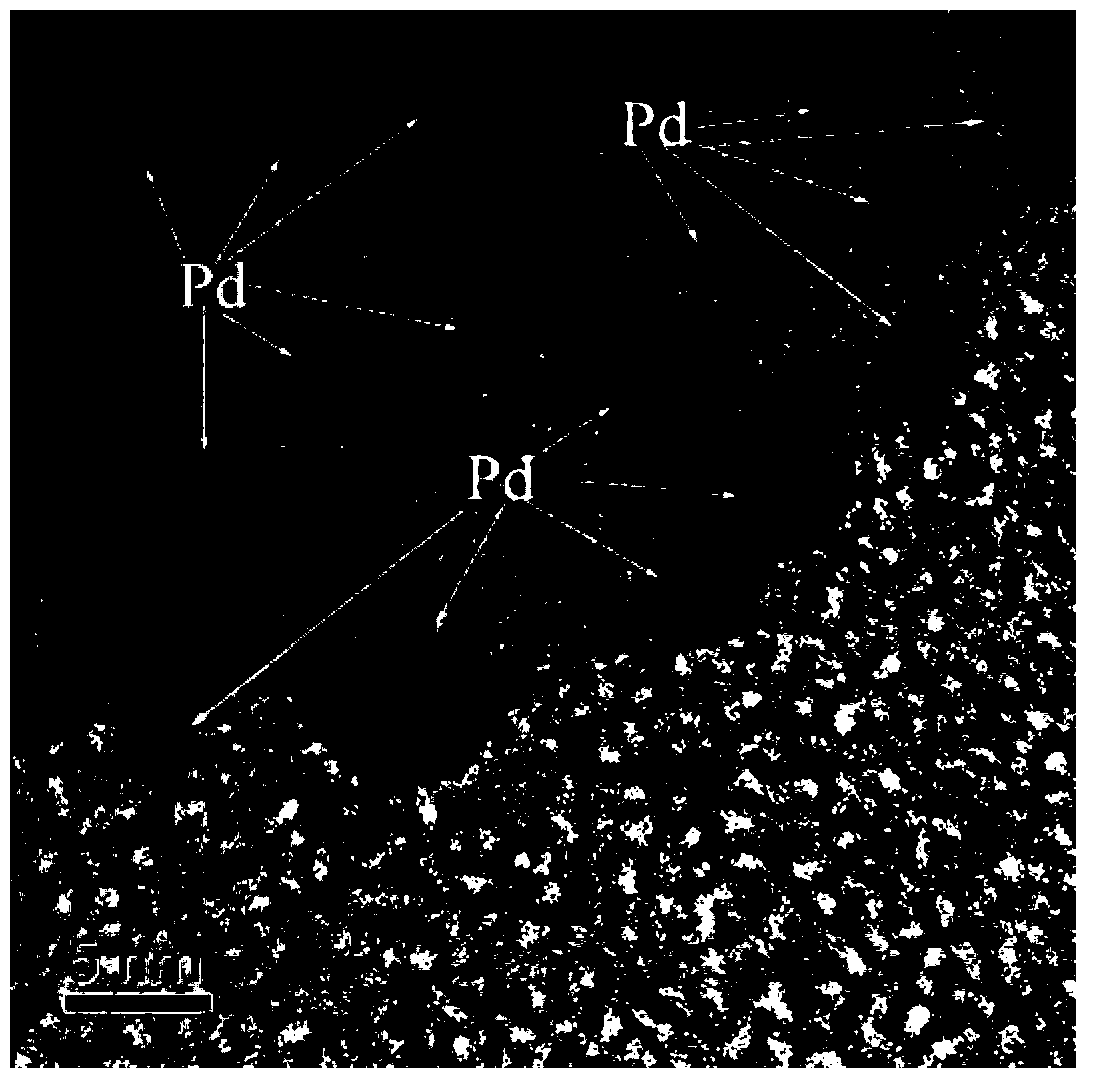

[0033] ④ The carrier impregnated with the aqueous solution ③ is dried and calcined to prepare the catalyst to obtain the catalyst BC-1, wherein the Pd content is 0.01% of the total weight, and the palladium nanoparticle particle size distribution is 1-5 nm.

Embodiment 2

[0035] ①Pipe 50mgPd / ml of Pd(NO 3 ) 2 Solution 4ml, diluted to 100g with deionized water solution;

[0036] ②In a constant temperature water bath at 20℃, dissolve 0.2g of cationic stabilizer Polyquaternium-10 in 400g of deionized water, magnetically stir for 2h, then add ① to ②, while adjusting the pH with sodium hydroxide To neutral, stir for another 2h to obtain an aqueous solution containing nanoparticles, wherein the weight ratio of deionized water, catalyst active component, stabilizer polyquaternium-10 is = 1:0.0004:0.0004;

[0037] ③Weigh the tooth shape Al 2 O 3 Carrier 100g, on which 50g of the above-prepared aqueous solution is impregnated;

[0038] ④ The carrier impregnated with the aqueous solution ③ is dried and calcined to prepare the catalyst to obtain the catalyst BC-2, wherein the Pd content is 0.02% of the total weight, and the palladium nanoparticle particle size distribution is 1-8nm.

Embodiment 3

[0040] ①Pipe 50mgPd / ml of Pd(NO 3 ) 2 Solution 6ml, diluted to 100g with deionized water solution;

[0041] ②In a constant temperature water bath at 20℃, dissolve 0.3g of non-ionic stabilizer hydroxyethyl cellulose in 400g of deionized water, magnetically stir for 2h, then add ① to ② while adjusting the pH with sodium hydroxide To neutral, stir for 2 hours to obtain an aqueous solution containing nanoparticles, in which the weight ratio of deionized water, catalyst active components, and stabilizer hydroxyethyl cellulose is 1: 0.0006: 0.0006;

[0042] ③Weigh the tooth shape Al 2 O 3 Carrier 100g, on which 50g of the above-prepared aqueous solution is impregnated;

[0043] ④ The carrier impregnated with the aqueous solution ③ is dried and calcined to prepare the catalyst to obtain the catalyst BC-3, wherein the Pd content is 0.03% of the total weight, and the palladium nanoparticle particle size distribution is 1-10nm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com