Semi-dry kitchen waste continuous treatment system and method for treating kitchen waste

A technology of kitchen waste and treatment system, applied in the field of continuous treatment system of kitchen waste, can solve the problems of unstable operation of equipment, low efficiency of kitchen waste treatment, etc., and achieve the effects of saving volume, occupying a small area and manufacturing cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The inventors of the present invention found that most of the existing kitchen waste anaerobic digestion treatment equipment adopts dry or wet discontinuous operation mode, and all of them need to sort the kitchen waste and separate the solid and liquid, and the separated The water is only discharged into the sewer after removing the oil, and most of the separated solid components are landfilled or incinerated, which can easily cause pollution of the surrounding water, soil and atmospheric environment. This kind of food waste treatment method not only easily pollutes sewers because of the organic components in the water, but also increases the burden on urban public sewage treatment facilities, and can not recycle energy substances in food waste, which is wasteful and not environmentally friendly.

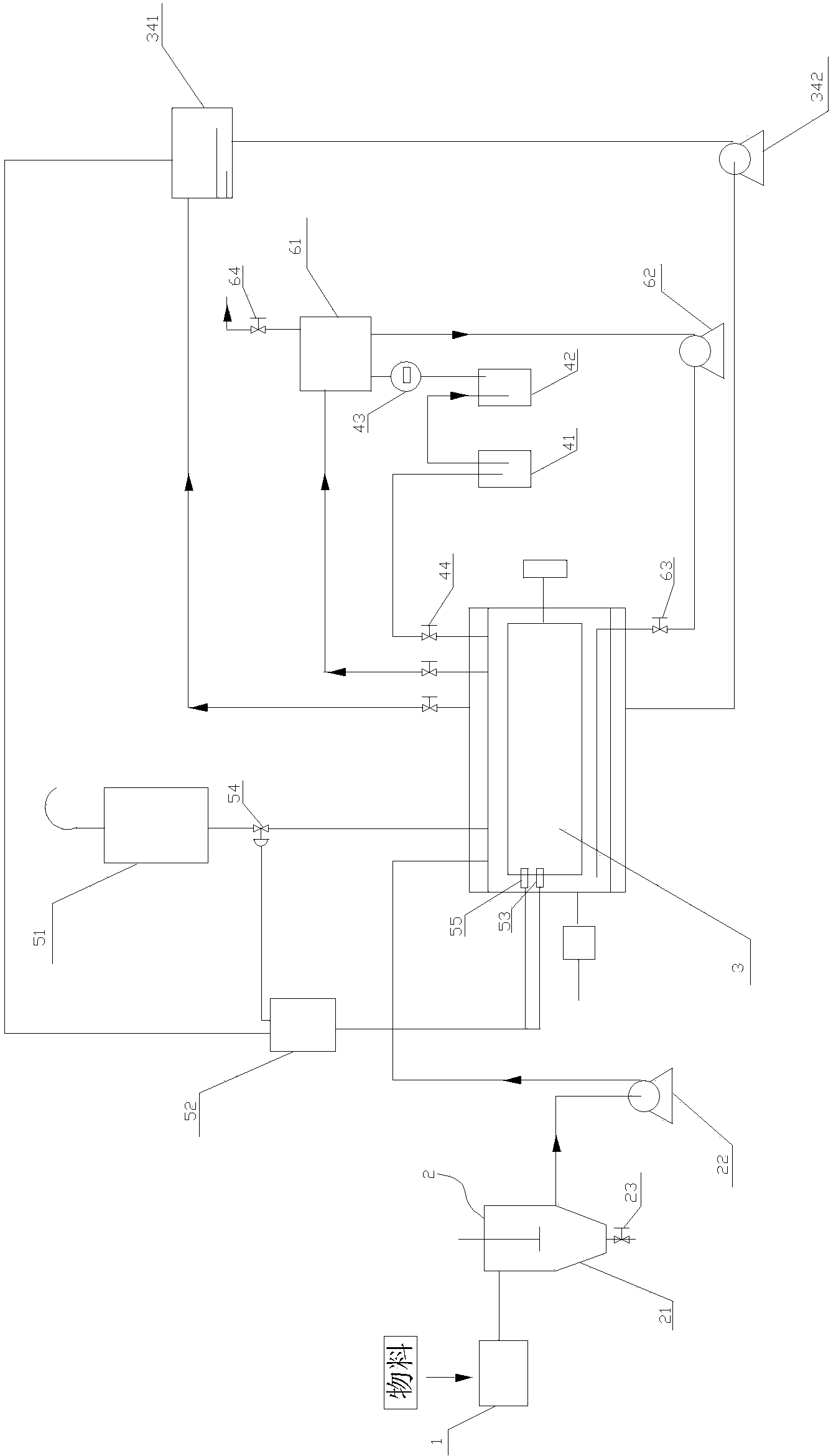

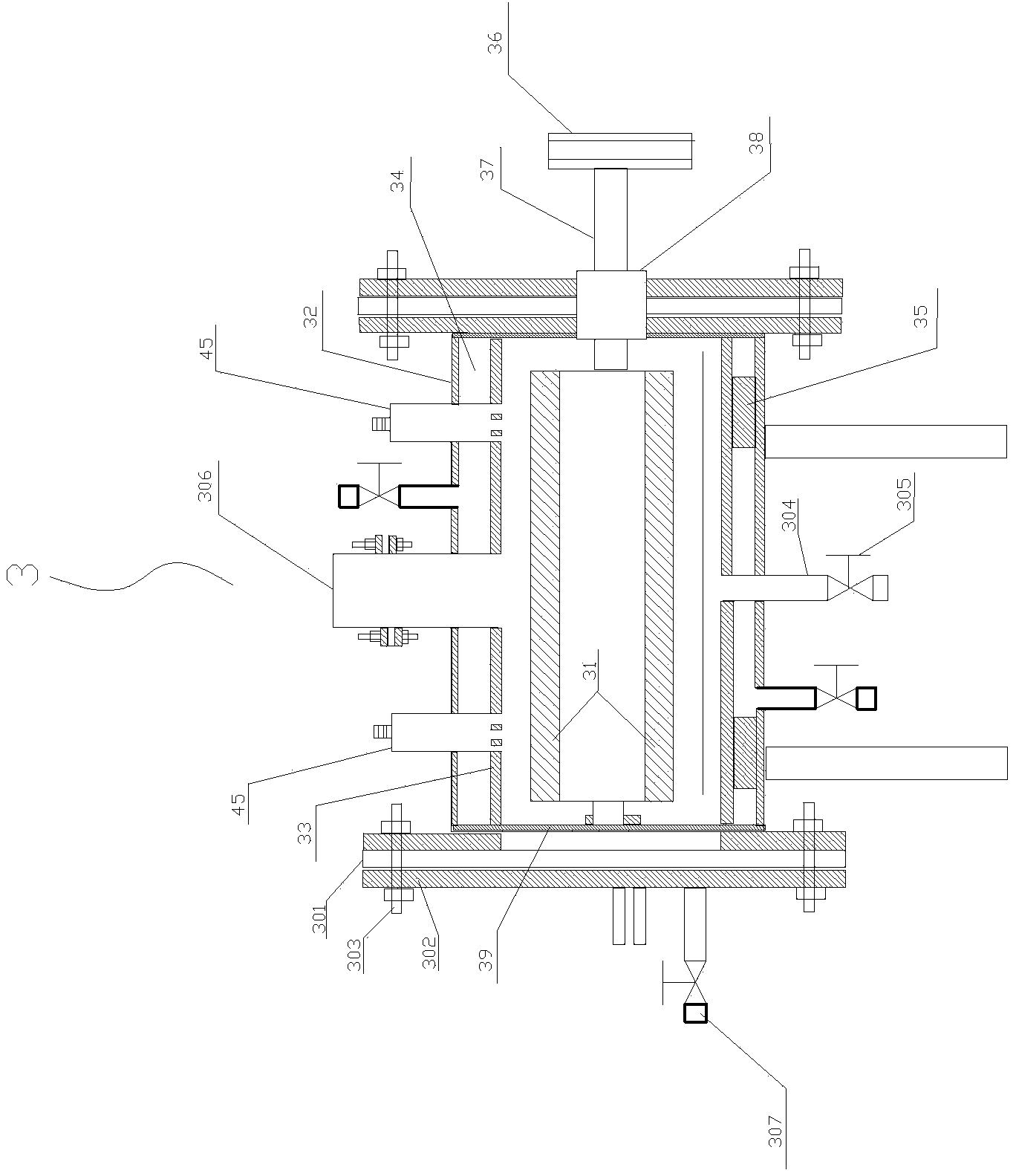

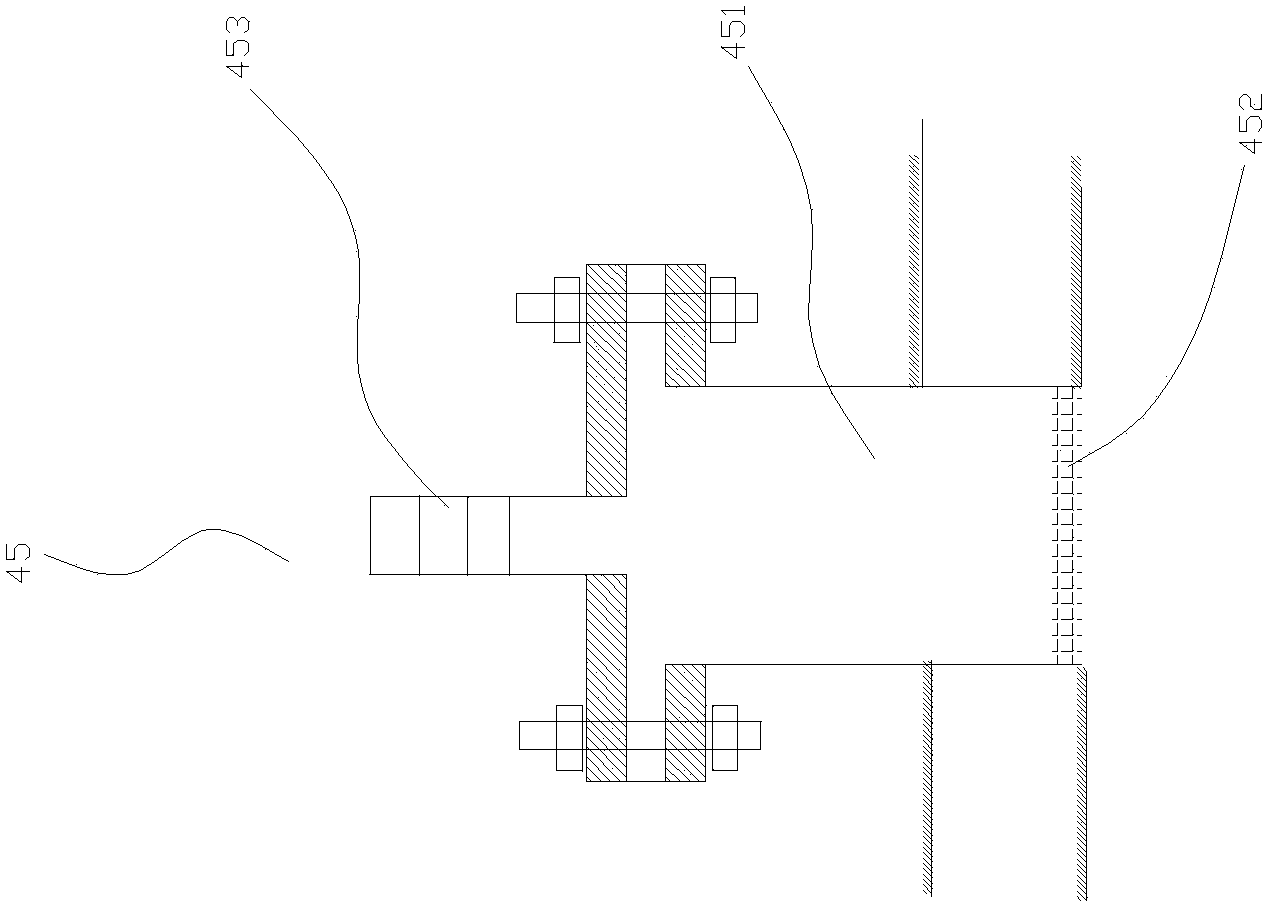

[0032] In view of the above problems, the inventor of the present invention proposes a technical solution, which is as follows: a semi-dry food waste treatment system, includ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com