Method and device for multi-head laser texturing processing of roller surface

A technology of laser texturing and rolling surface, applied in laser welding equipment, metal processing equipment, manufacturing tools, etc., can solve the problems of irregular textured point morphology, complicated control equipment, affecting the reflection effect of the board surface, etc., and achieve roughness. Good uniformity and deep drawing performance, improved wear resistance and service life, and high laser energy utilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

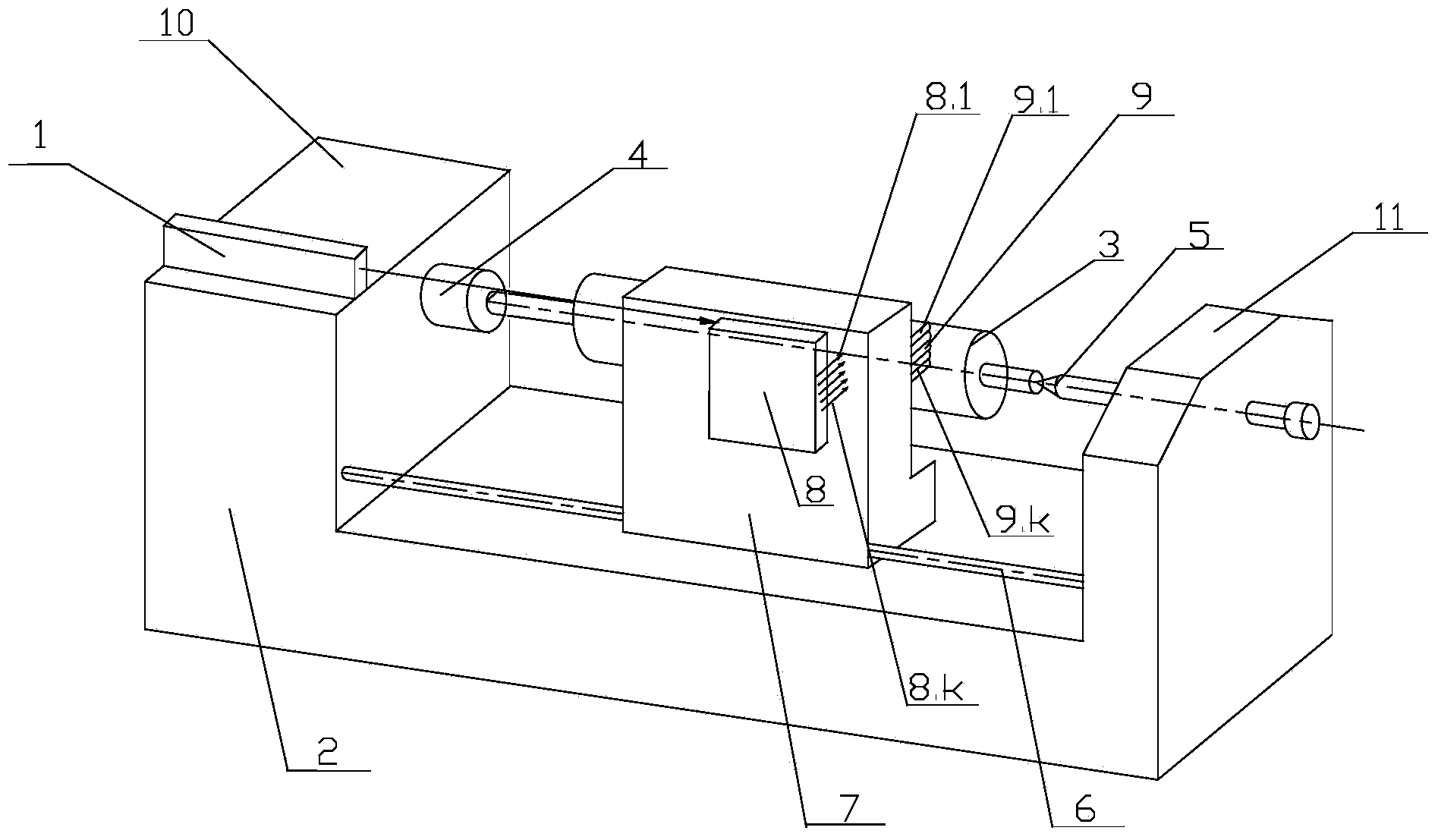

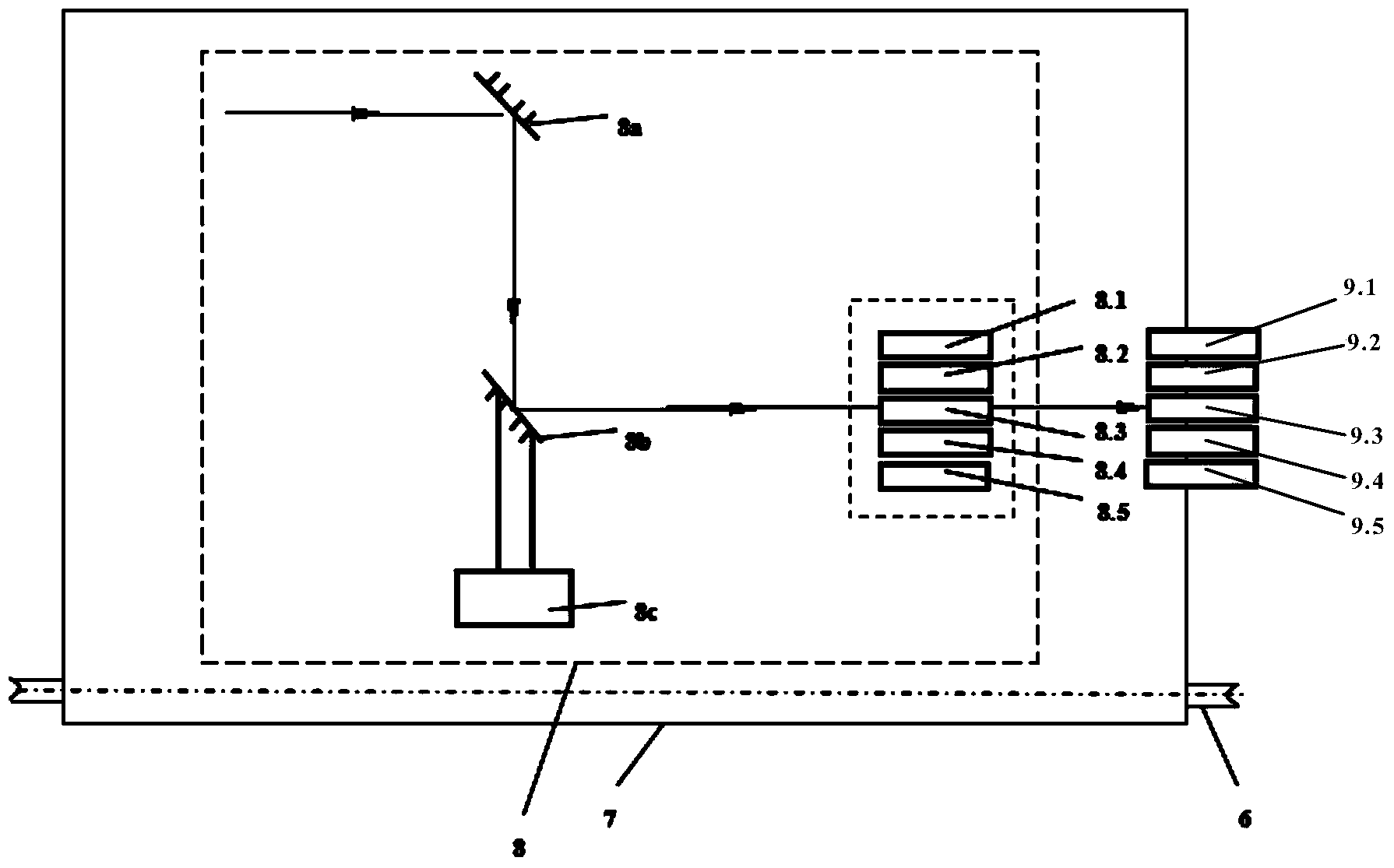

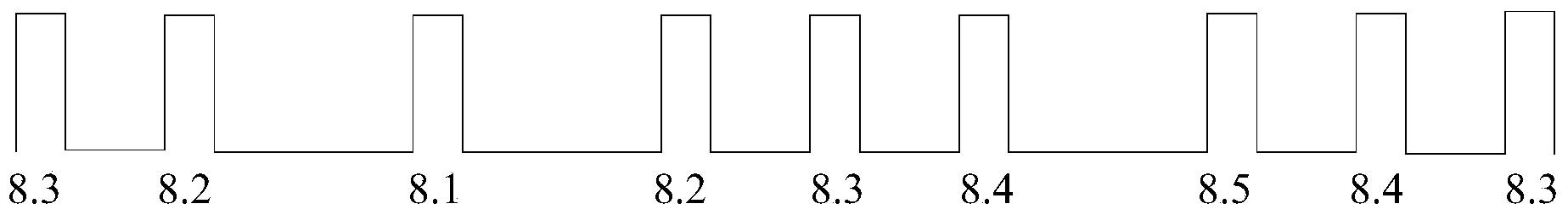

[0037] Such as figure 2 As shown, the vibration splitting mechanism 8 in Embodiment 1 has five parallel splitting heads, namely the first splitting head 8.1, the second splitting head 8.2, the third splitting head 8.3, the fourth splitting head 8.4 and the fifth splitting head 8.5 . Correspondingly, the laser focusing mechanism 9 in Embodiment 1 has five parallel focusing heads, that is, the first focusing head 9.1, the second focusing head 9.2, the third focusing head 9.3, the fourth focusing head 9.4 and the fifth focusing head. Focus head 9.5. The laser beam emitted by the laser 1 passes through the first total reflection mirror 8a, the optical path changes by 90°, and enters the second total reflection mirror 8b fixed to the vibrating device 8c, and the optical path changes by 90° again. When the second total reflection mirror 8b was at the amplitude zero point, the laser beam just entered the third beam splitting head 8.3 in the middle position, and when the second tot...

Embodiment 2

[0045] Embodiment 2 has the same basic structure as Embodiment 1, and the working principle is also the same. Only the number of beam-splitting heads of its vibrating beam-splitting mechanism 8 is slightly different from the number of focusing heads of the laser focusing head mechanism 9 .

[0046] Such as Figure 5 As shown, the vibration splitting mechanism 8 in Embodiment 2 has seven parallel splitting heads, i.e. the first splitting head 8.1, the second splitting head 8.2, the third splitting head 8.3, the fourth splitting head 8.4, the fifth splitting head 8.5 , the sixth split light head 8.6 and the seventh split light head 8.7. Correspondingly, the laser focus mechanism 9 in Embodiment 2 has seven parallel focus heads, that is, the first focus head 9.1, the second focus head 9.2, the third focus head 9.3, the fourth focus head 9.4 and the fifth focus head. Focusing head 9.5, sixth focusing head 9.6 and seventh focusing head 9.7.

[0047] In Example 2, the material of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com