Helium low-pressure recycling, purification and storage device and application method thereof

A storage device, helium technology, applied in chemical instruments and methods, inert gas compounds, inorganic chemistry, etc., can solve the problems of not being widely used, complex low-temperature fractionation technology, and high requirements for compressor equipment, etc. Achieve broad market application and promotion prospects, reduce the probability of explosion accidents, and have the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

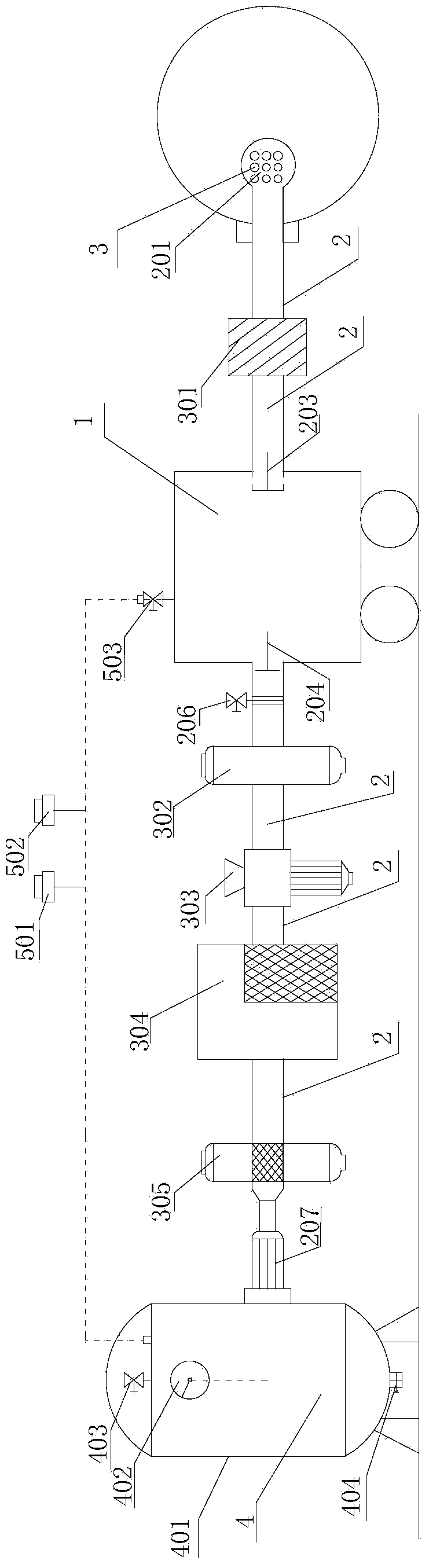

[0036] Such as figure 1 As shown, a helium low-pressure recovery, purification and storage device includes a pipeline system and a compression system 1 connected by the pipeline system, a filtration purification system and a helium storage system 4 at the end, and the filtration purification system includes Crude helium filter 301, oil-water separator 303, cold dryer 304 and adsorption cylinder 305, described crude helium filter 301 is installed on the intake pipe of compression system 1, oil-water separator 303, cold dryer 304 and adsorption cylinder 305 Installed on the outlet pipe of the compression system 1 respectively, the cold dryer 304 and the adsorption cylinder 305 are used together to achieve the effect of low-temperature adsorption.

[0037] Wherein, the pipeline system includes the pipeline 2 connecting the compression system 1, the filtration and purification system and the helium storage system 4, the intake probe 201 arranged at the beginning, the intake valve ...

Embodiment 2

[0043]The difference between this embodiment and Embodiment 1 is that the filtration and purification system also includes a primary filter 302, and the pipeline system also includes a pressure regulating valve 206 for adjusting the discharge air pressure of the compression system 1, the inlet probe 201, the crude helium filter device 301, inlet valve 203, compression system 1, outlet valve 204, pressure regulating valve 206, primary filter 302, oil-water separator 303, cold dryer 304, adsorption cylinder 305, high-pressure inflation exhaust 207, and helium storage system 4 The pipelines 2 are connected sequentially, and the compression system 1, filtration purification system and pipeline system are arranged on a trolley for easy transportation and adjustment.

[0044] The working process and working principle of the present invention: the helium in the aerostat passes through the air inlet probe and the coarse helium filter to filter out some coarser particles, then compresse...

Embodiment 3

[0046] A method for recovering, purifying and storing helium in an aerostat, using the low-pressure recovery, purification and storage device for helium described in Embodiment 1 or 2, specifically comprising the following steps:

[0047] a. Absorb the crude helium in the aerostat through the suction hole on the spherical air intake probe;

[0048] b. The inhaled crude helium first passes through the crude helium filter to filter out the coarse particles in the crude helium;

[0049] c. Then enter the compression system for compression, and the compressed helium passes through the pressure regulating valve to control the air pressure to meet the set requirements;

[0050] d. Helium is initially filtered through the primary filter to further filter out the remaining gas impurities;

[0051] e. Then the helium passes through the oil-water separator to remove the oil and water in the compressed gas;

[0052] f. After dehydration and oil removal, the helium is cooled and dried b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com