Method for preparing catalyst used for methanol/dimethyl ether high selectivity propylene preparation

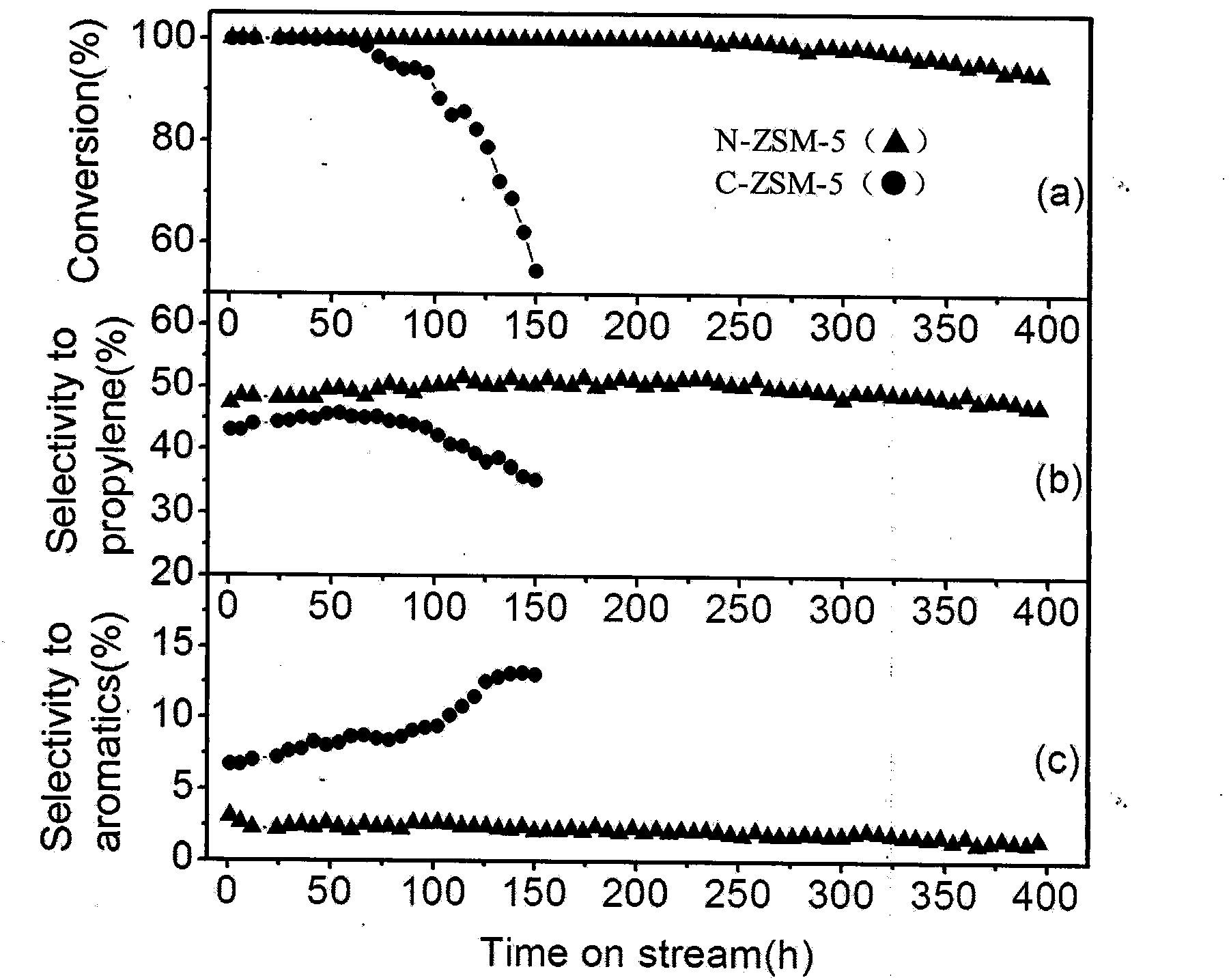

A catalyst, dimethyl ether technology, applied in the field of preparation of nano-layered structure ZSM-5 molecular sieve, can solve the problems of short channel length, unreported product distribution, short life and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

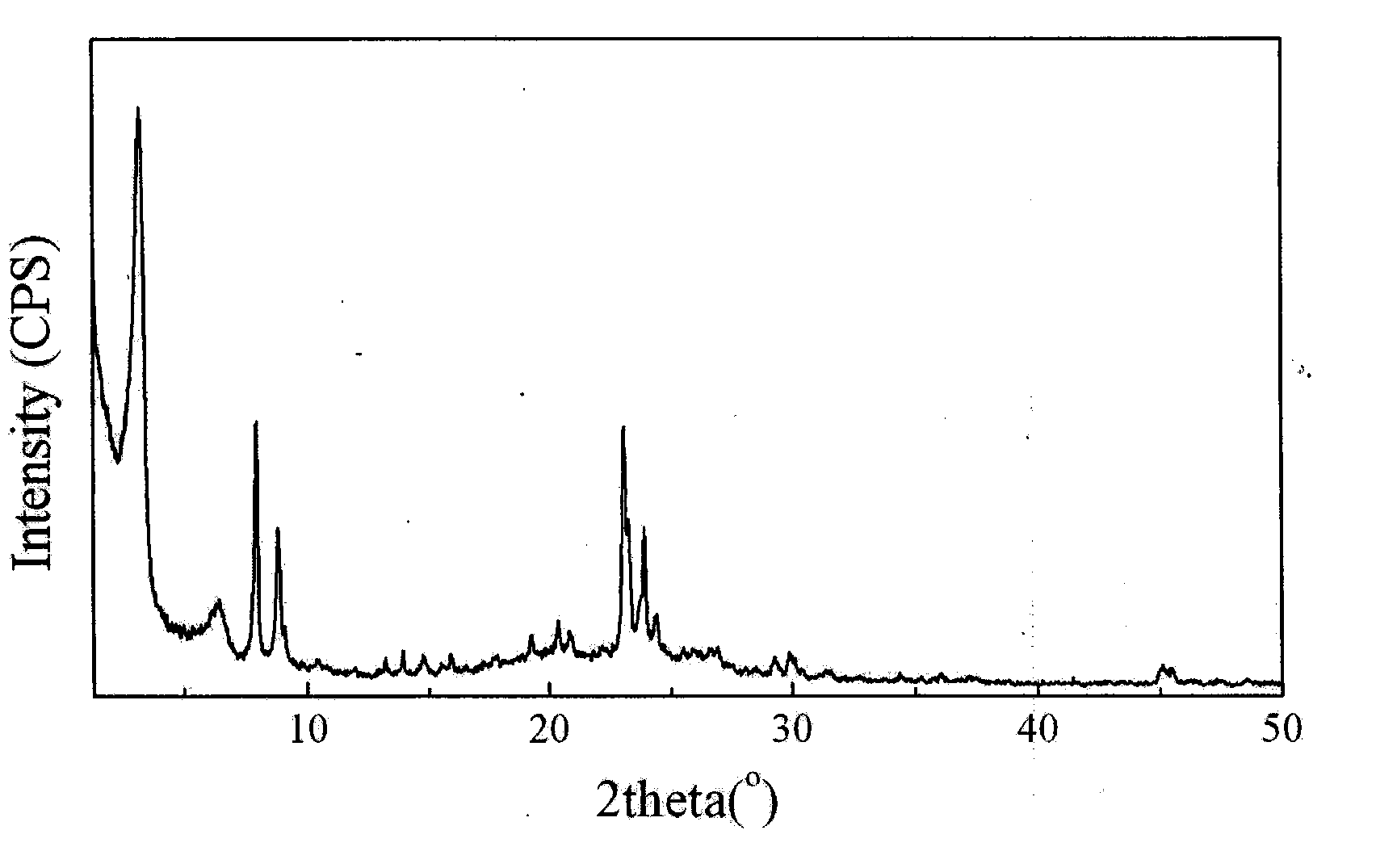

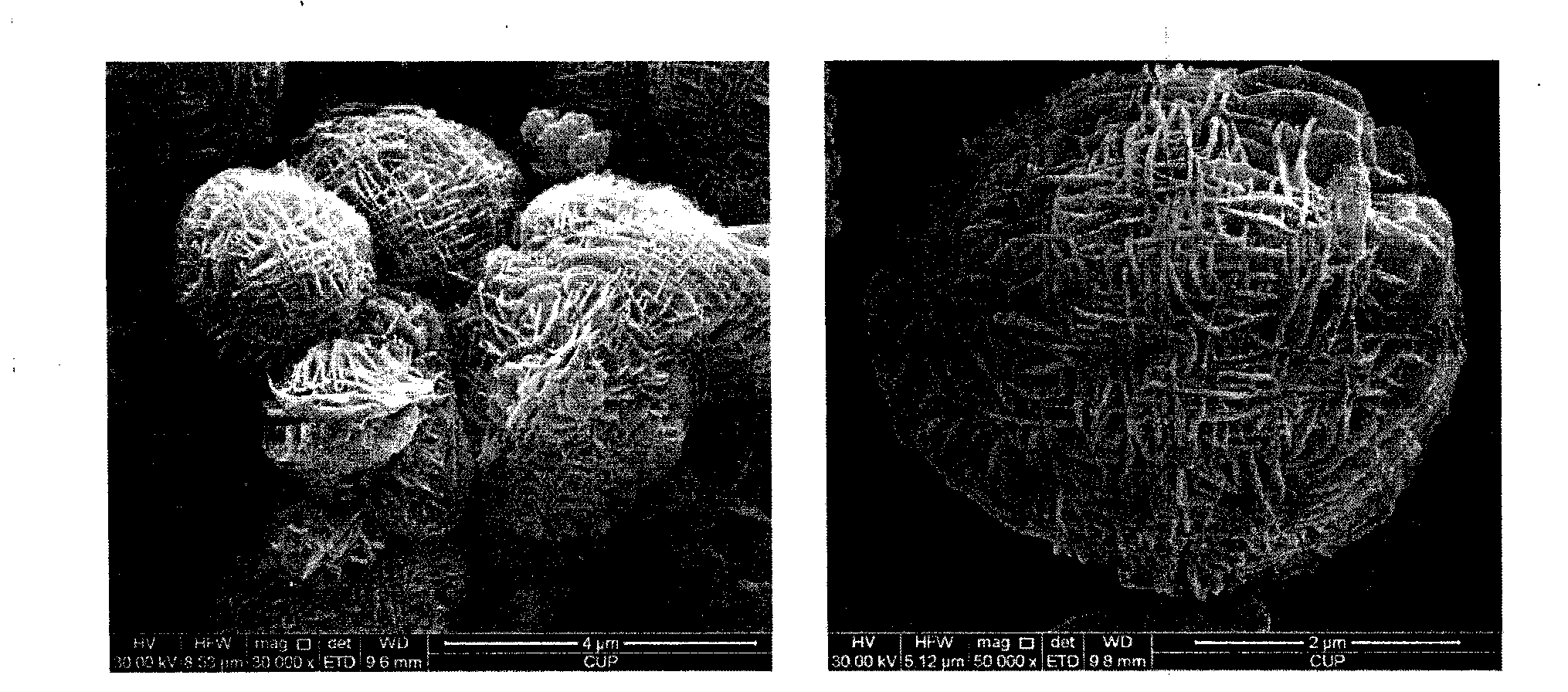

Embodiment 1

[0032] Add 6.10g of SDA (C18-6-6) into a mixed solution of 21.5g of absolute ethanol and 30g of deionized water, stir at 60°C for 4h to prepare liquid A; add 0.84g of concentrated H2SO4 into 20.24g of deionized water , after mixing evenly, add 0.624g Al2(SO4)3·18H2O (>99%), stir until mixing evenly to prepare B liquid. Slowly add liquid B dropwise to liquid A, and continue to stir in a 60°C water bath for 4 hours after the addition is complete, then slowly add 20 g of water glass (SiO2 > 28.08 wt%), and stir for 6 hours to form an initial gel, wherein the molar composition of the gel is 0.01 Al2O3:SiO2:0.08SDA:0.10NaO2:0.12SO42-:30H2O:5C2H5OH. The mixed gel was crystallized in an oven at 150°C for 5 days, and the product was filtered, washed and dried to obtain a nano-layered ZSM-5 molecular sieve powder with high crystallinity.

Embodiment 2

[0034] Add 7.62g of SDA (C18-6-6) into a mixed solution of 34.45g of absolute ethanol and 40g of deionized water, stir at 60°C for 4h to prepare liquid A; add 0.98g of concentrated H2SO4 into 20.5g of deionized water , after mixing evenly, add 0.312g Al2(SO4)3·18H2O (>99%), stir until mixing evenly to prepare B liquid. Slowly add liquid B dropwise to liquid A, and continue to stir in a 60°C water bath for 4 hours after the addition is complete, then slowly add 20 g of water glass (SiO2 > 28.08 wt%), and stir for 6 hours to form an initial gel, wherein the molar composition of the gel is 0.005 Al2O3:SiO2:0.1SDA:0.10NaO2:0.12SO42-:36H2O:8C2H5OH. The mixed gel was crystallized in an oven at 150°C for 5 days, and the product was filtered, washed and dried to obtain a nano-layered ZSM-5 molecular sieve powder with high crystallinity.

Embodiment 3

[0036] Add 9.14g of SDA (C18-6-6) into a mixed solution of 51.67g of absolute ethanol and 40g of deionized water, stir at 60°C for 4h to prepare liquid A; add 1.31g of concentrated H2SO4 into 13.85g of deionized water , after mixing evenly, add 0.208g Al2(SO4)3·18H2O (>99%), stir until mixing evenly to prepare B liquid. Slowly add liquid B dropwise to liquid A, and continue to stir in a 60°C water bath for 4 hours after the addition is complete, then slowly add 20 g of water glass (SiO2 > 28.08 wt%), and stir for 6 hours to form an initial gel, wherein the molar composition of the gel is 0.0033Al2O3:SiO2:0.12SDA:0.10NaO2:0.15SO42-:32H2O:12C2H5OH. The mixed gel was crystallized in an oven at 150°C for 5 days, and the product was filtered, washed and dried to obtain a nano-layered ZSM-5 molecular sieve powder with high crystallinity.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com