Production method for recombinant humanized superoxide dismutase

A superoxide and production method technology, applied in the field of bioengineering, can solve problems such as limited sources of human SOD, production of bacterial endotoxin, cumbersome SOD purification methods, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

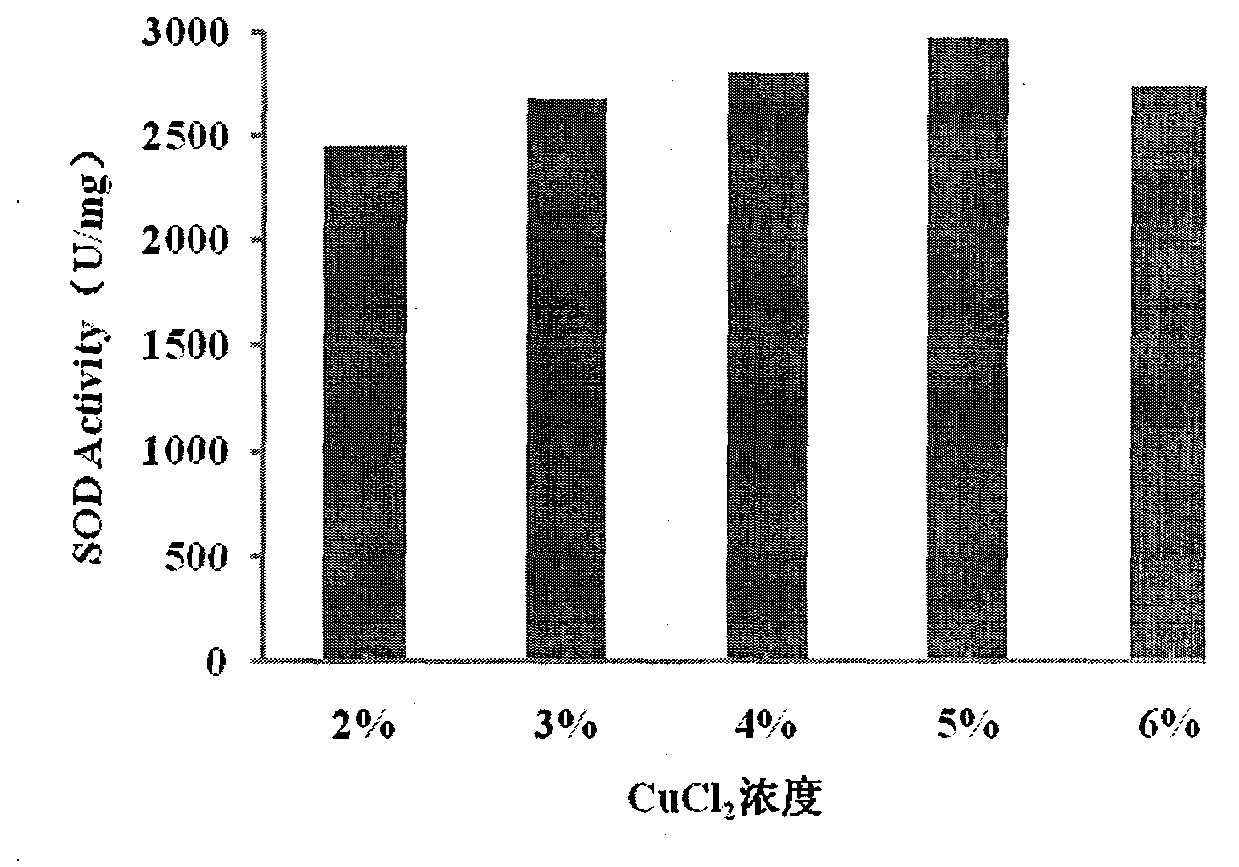

[0017] Centrifuge the 60L fermentation broth with a tube centrifuge at a speed of 16000rpm and a flow rate of 0.6-0.8mL / min. Collect the fermented bacteria, suspend them according to the ratio of the wet weight of the bacteria to the volume of pure water 1:10, and use a high-pressure homogenizer Broken, crushing pressure is 880bar, broken once. Add 2%, 3%, 4%, 5%, 6% volume of 10mmol / L CuCl to the mixed solution after crushing 2 Then pass it into the spiral tube heater, 65°C, 20min. After centrifugation, discard the pellet. The supernatant is treated with a membrane, firstly through a 5μm pretreatment membrane to remove impurities and cell debris; then through a 0.22μm filter membrane to remove bacteria; finally with a 6kDa ultrafiltration membrane to remove salt and small molecular impurities, and concentrate to 15L. The concentrated solution is subjected to DEAE-Sephadex A50 column chromatography, and gradient elution is performed with a potassium phosphate buffer solutio...

Embodiment 2

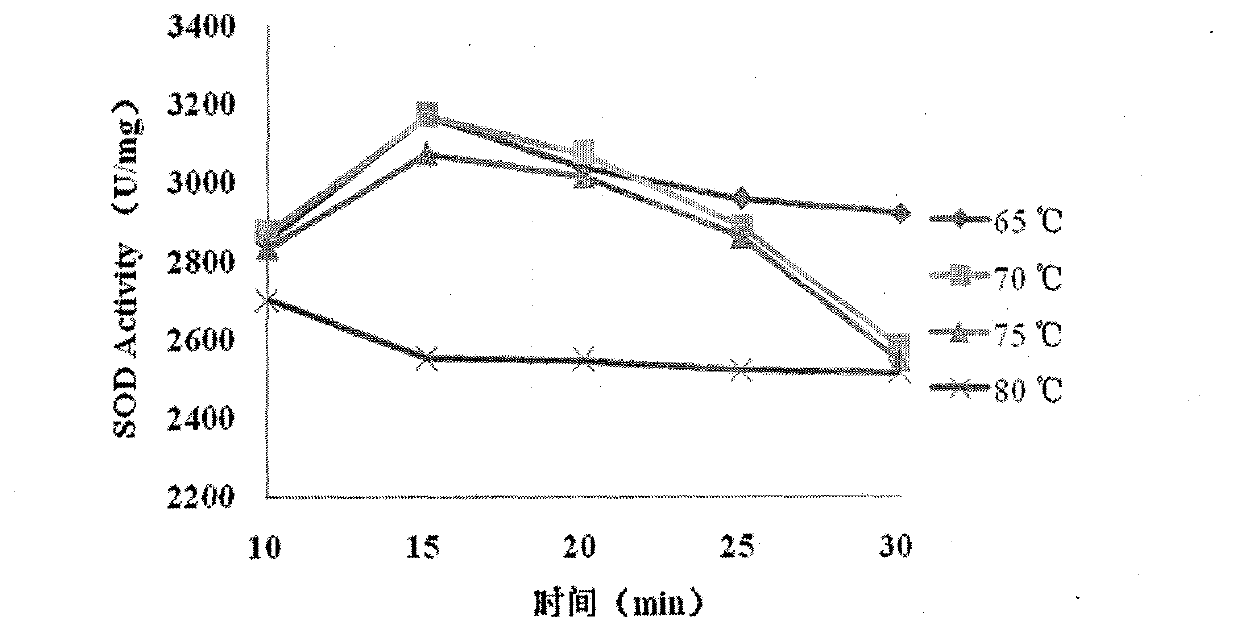

[0019] Centrifuge 60L fermentation broth with a tubular centrifuge, speed: 16000rpm, flow rate: 0.6-0.8mL / min, collect the fermented bacteria, suspend according to the ratio of the wet weight of the bacteria to the volume of pure water 1:10, and use a high-pressure homogenizer Broken, crushing pressure is 880bar, broken once. Add 5% volume of 10mmol / L CuCl to the mixed solution after crushing 2 Then pass it into the spiral tube heater, set the temperature at 65°C, 70°C, 75°C, 80°C, control the speed of the peristaltic pump so that the time from entry to exit is controlled as 10min, 15min, 20min, 25min, 30min respectively, centrifuge Afterwards, the precipitate was discarded. The supernatant is treated with a membrane, firstly through a 5μm pretreatment membrane to remove impurities and cell debris; then through a 0.22μm filter membrane to remove bacteria; finally with a 6kDa ultrafiltration membrane to remove salt and small molecular impurities, and concentrate to 15L. The ...

Embodiment 3

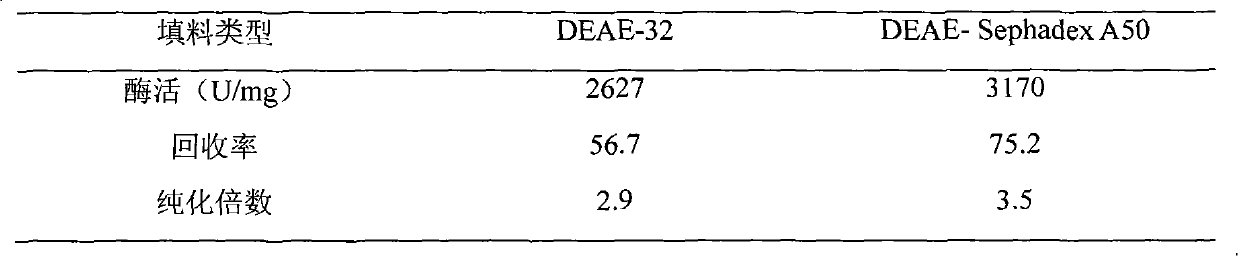

[0021] Centrifuge 60L fermentation broth with a tubular centrifuge, speed: 16000rpm, flow rate 0.6-0.8mL / min: collect the fermented bacteria, suspend them according to the ratio of wet weight of bacteria to volume of pure water 1:10, and crush them with a high-pressure homogenizer , crushing pressure is 800bar, crushing once. Add 5% volume of 10mmol / L CuCl to the mixed solution after crushing 2 Then pass it into the spiral tube heater, set the temperature at 70°C, control the speed of the peristaltic pump so that the time from entering to exiting is 15 minutes, centrifuge, and discard the precipitate. The supernatant is treated with a membrane, firstly through a 5μm pretreatment membrane to remove impurities and cell debris; then through a 0.22μm filter membrane to remove bacteria; finally with a 6kDa ultrafiltration membrane to remove salt and small molecular impurities, and concentrate to 15L. The concentrate was subjected to column chromatography on DEAE-32 and DEAE-Sepha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com