Chip component tip packaging paste and preparation method of chip component

A technology for encapsulating slurry and components, which is applied in the direction of coating resistance materials and resistors with negative temperature coefficients, etc., to achieve the effects of qualified reliability, improved precision pass rate, and moderate viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] This embodiment provides a paste for encapsulating the end of a chip component made of mixing raw materials with different mass ratios. The metal powder, polymer resin, calcium carbonate, and organic solvent are mechanically stirred according to the mass percentage of 40%: 20%: 20%: 20%, wherein the speed of mechanical stirring is 60-100r / min, more preferably 70% -90r / min, stirring and mixing to form an encapsulating slurry, the viscosity is about 150-170Pa*s at 25°C, and the solid content is 70-80%.

[0023] In the embodiment of the encapsulation slurry at the end of the chip component, the mass percentage of metal powder, polymer resin, calcium carbonate, and organic solvent can also be: 40%: 20%: 25%: 15%, or 45%: 20%: 20%: 15%, or 35%: 25%: 30%: 10%, or 40%: 15%: 35%: 10%.

[0024] In addition, it should be noted that silver powder is the best metal powder in this embodiment.

Embodiment 2

[0026] This embodiment provides a method for preparing a chip component by encapsulating the end of the chip component with an encapsulation slurry. This embodiment uses the example of using a thermistor high-precision chip as a chip component, and the encapsulation process of its end includes the following steps:

[0027] (1) Silver powder, polymer resin, calcium carbonate, and organic solvent are mixed according to the mass percentage of 40%: 20%: 25%: 15% respectively to form an encapsulating slurry, wherein the organic solvent can be propyl acetate and ethanol according to The ratio of mass percentage is 3:1 mixed mixture, and the polymer resin can be epoxy resin.

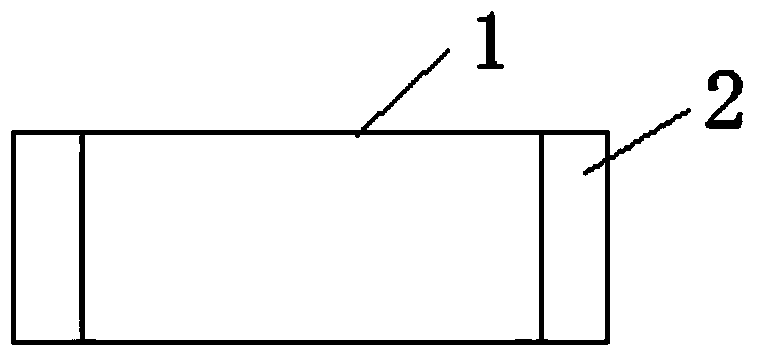

[0028] (2) Use a screen printing machine to print the prepared encapsulation slurry on the end of the high-precision chip of the thermistor on a screen of 300-450 mesh, and print an encapsulation protective layer with a thickness of 15-50 μm, such as figure 1 Shown is the thermistor high-precision chip 1 encap...

Embodiment 3

[0038] This embodiment also provides a method for preparing a chip component by encapsulating the encapsulating slurry on the end of the chip component. This embodiment also uses the example of using a thermistor high-precision chip as a chip component, and the encapsulation process of its end is basically the same as the preparation method of Embodiment 2. The difference is that in this embodiment, silver powder, polymer resin, carbonic acid Calcium and organic solvent are respectively 45%: 20%: 20%: 15% by mass percentage.

[0039] Randomly select 30 0402 chips with a nominal resistance value of 47kΩ made according to the above formula, and test their resistance values, see Table 2 for details.

[0040] Table 2 (unit: kΩ)

[0041] Numbering

[0042] Numbering

[0043] In this embodiment, the high-precision thermistor product made by using the encapsulating slurry has a 1% accuracy pass rate of 76.6%, and the encapsulating slurry can greatly ensure the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com