Integration method of leadless planar surface mounting type thick film hybrid integrated circuit

A thick-film hybrid and integrated circuit technology, which is applied in the direction of circuits, electrical components, and electric solid-state devices, can solve the problem of no lead-free planar surface-mounted thick-film hybrid integrated circuits, etc., and achieve broad market prospects and application space and volume The effect of shrinking and improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

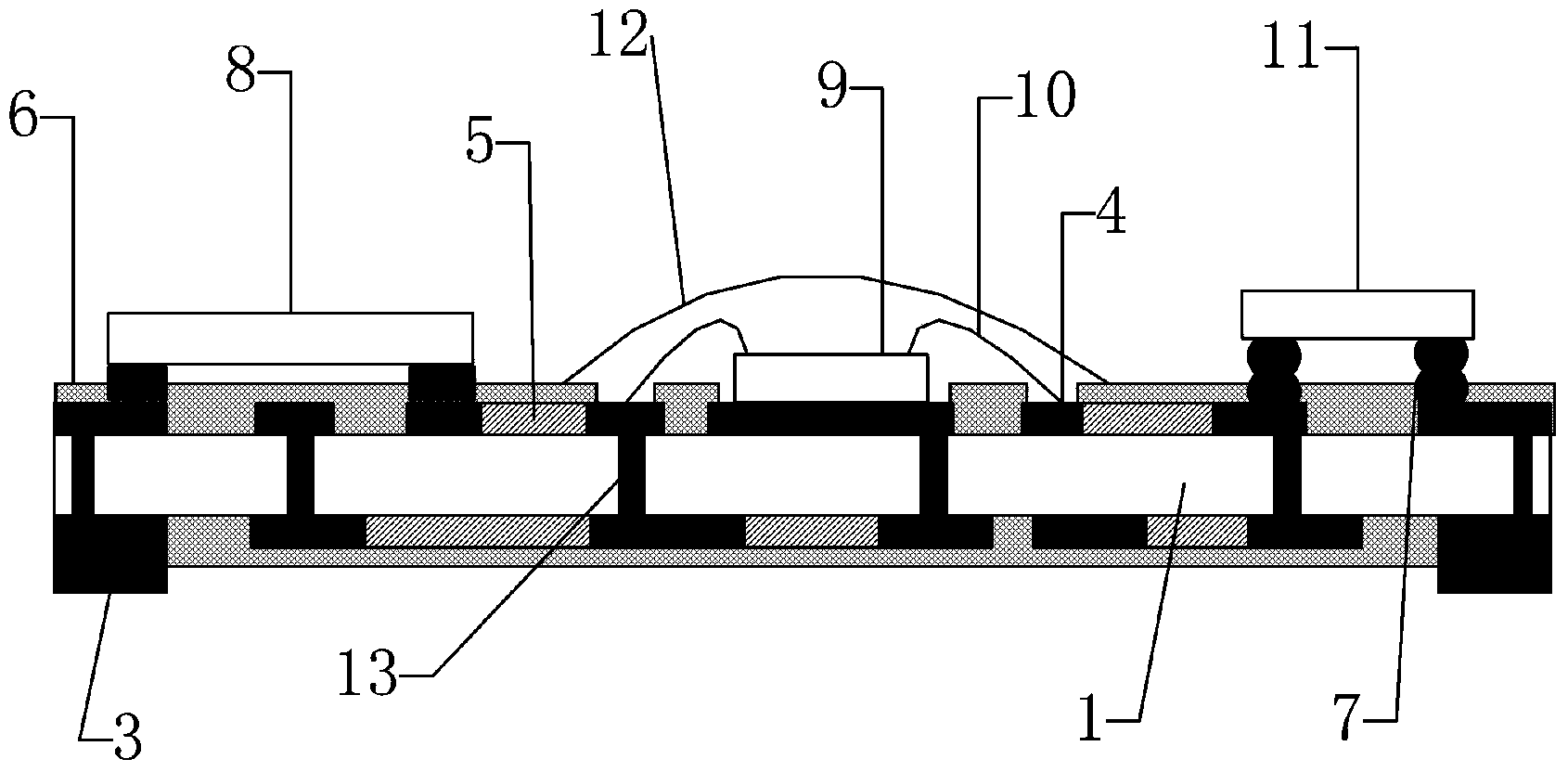

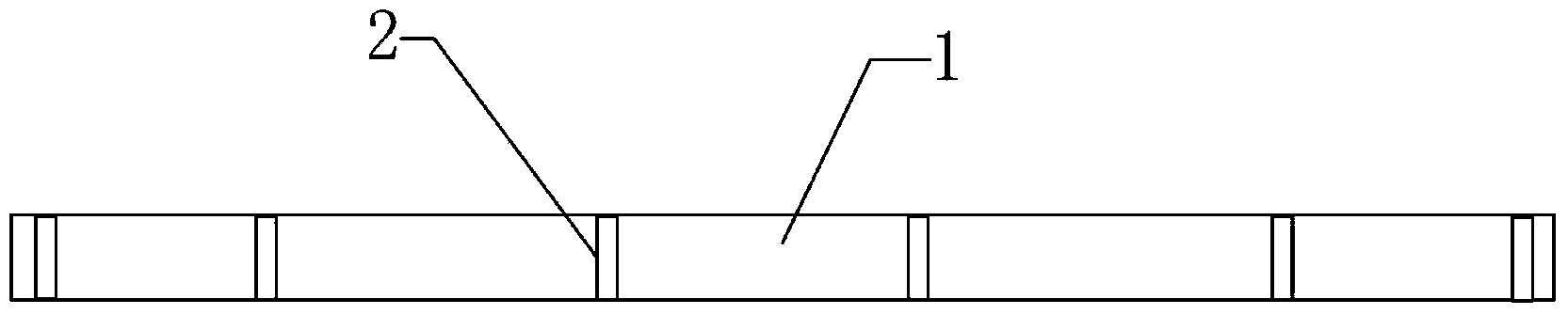

[0018] Embodiment: the technological process of the inventive method is as Figure 10 As shown, the process includes the following steps:

[0019] (1) Preparation of ceramic substrate, gold paste, and ruthenium-based resistor paste;

[0020] (2) Cleaning and drying of substrates, cleaning and drying of shells;

[0021] (3) The substrate is drilled through the hole, and the aperture accuracy is controlled within 0.1 μm;

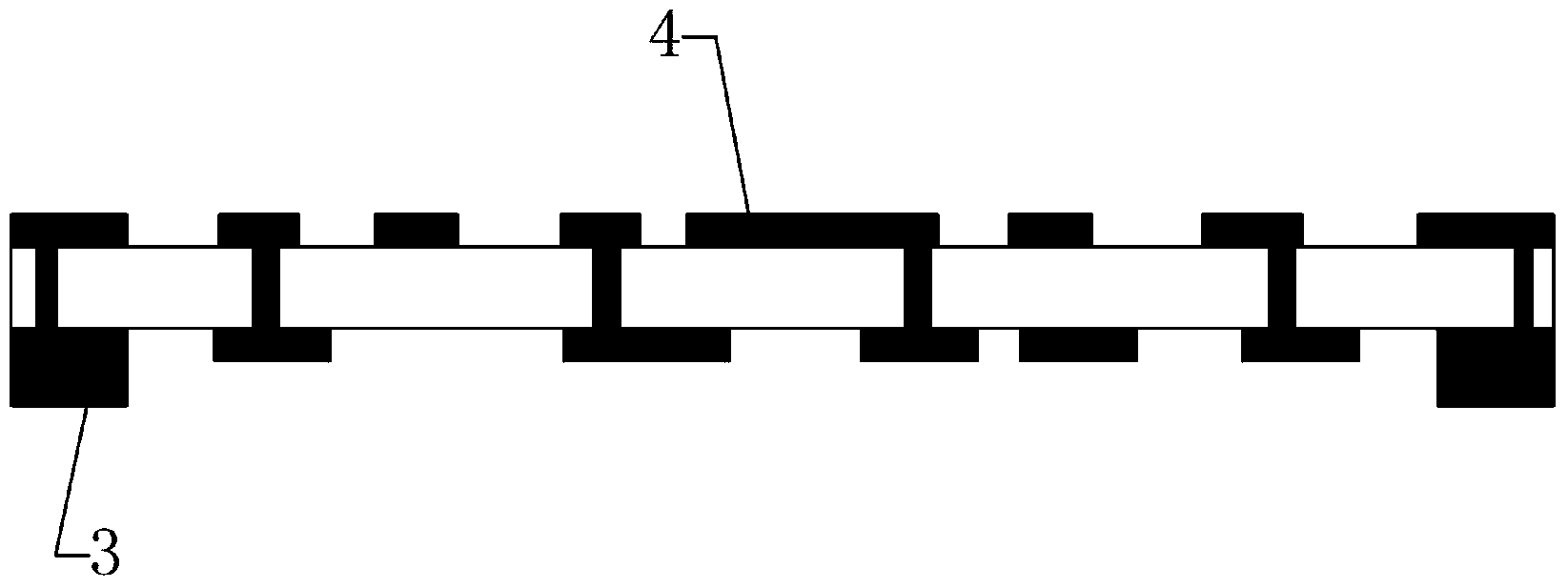

[0022] (4) Thick-film conductor paste printed conduction tape, and dried at 150°C for 10 minutes;

[0023] (5) Through-hole metal paste filling;

[0024] (6) The welding surface of the terminal is thickened and printed once;

[0025] (7) Print the stop band with resistive paste, and dry it at 150°C for 10 minutes;

[0026] (8) Film formation is sintered at 850°C for 10 minutes, and the total time of film formation and sintering is 35 minutes;

[0027] (9) Laser adjustment resistance;

[0028] (10) Electrical parameters and functional tests;

[0029] (1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com