Carbon nanotube heat storage textile, and preparation method thereof

A carbon nanotube and fabric technology, applied in the direction of fabrics, nanotechnology, nanotechnology, etc., can solve the problems of high preparation cost, rising preparation cost, inability to show heat storage and heat preservation effect, etc., and achieve excellent heat storage and heat preservation effect. low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

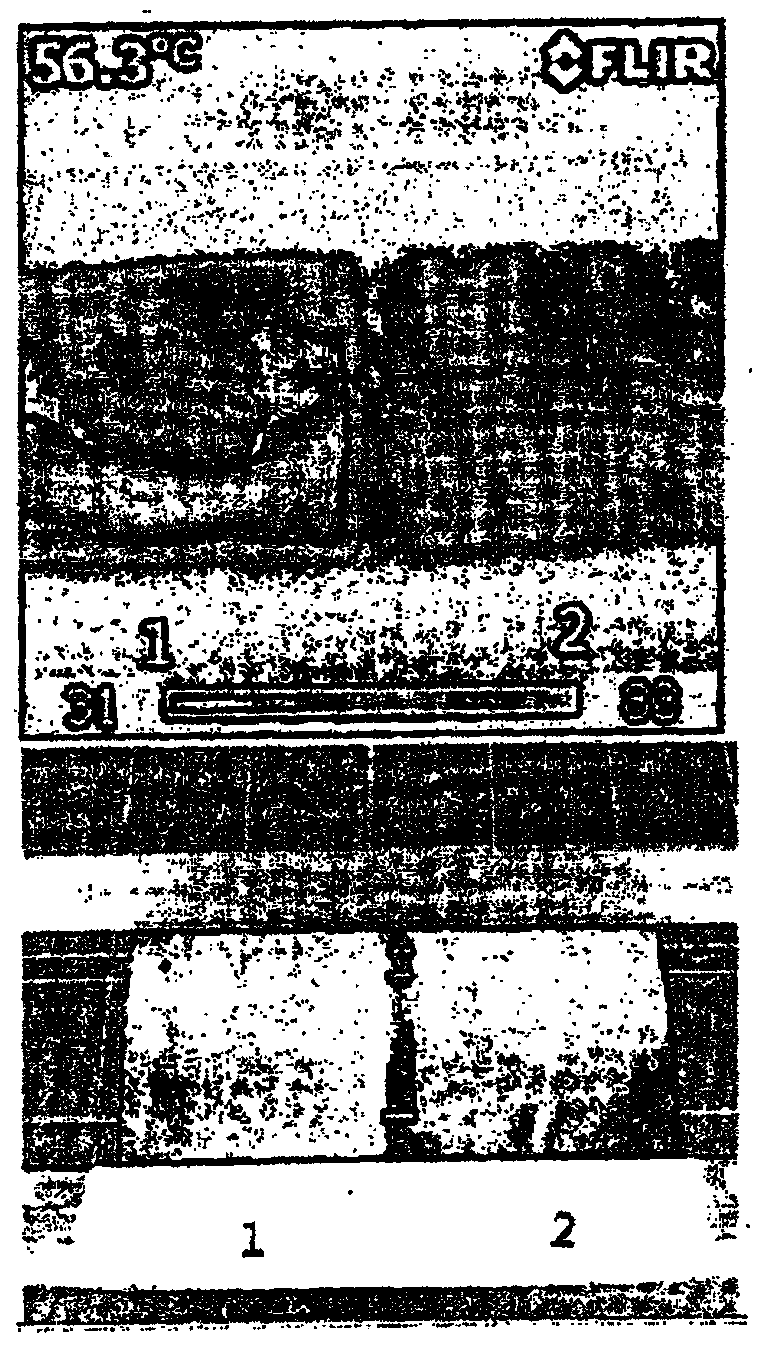

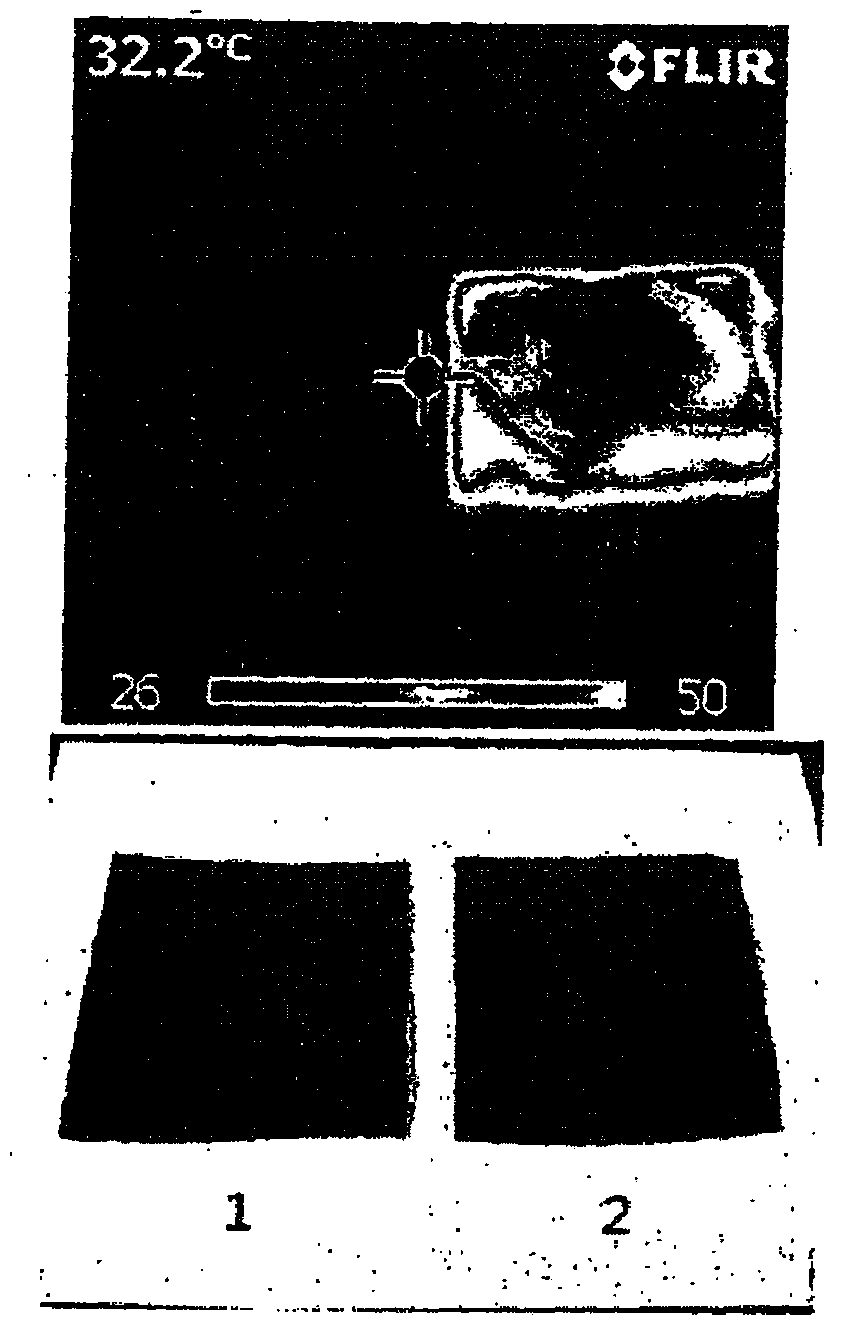

[0049] Preparation of the coating solution: when preparing the carbon nanotube coating solution of the present invention, the surface of the multi-walled carbon nanotubes is oxidized by using a mixed solution of nitric acid and sulfuric acid (3:1) to prepare a multi-walled carbon nanotube with improved dispersion performance. carbon nanotubes. 5% by weight of the above-mentioned multi-walled carbon nanotubes, dispersant (trade name: Triton X100 (Triton X100)) 5% by weight, defoamer (trade name: Surfynol 104H) 0.2% by weight and distilled water 38.8% by weight after acid treatment % to mix and apply ultrasonic waves at a power of 140W (70%) for 1 hour to disperse the carbon nanotubes. 50% by weight of a water-dispersible polyurethane binder (trade name: Sancure 12954) and 1% by weight of a tackifier (trade name: Carbopol EP-1) were mixed in the above dispersion liquid , and stirred in a mixer for 30 minutes to prepare a coating liquid.

[0050] Preparation of thermal storage ...

Embodiment 2

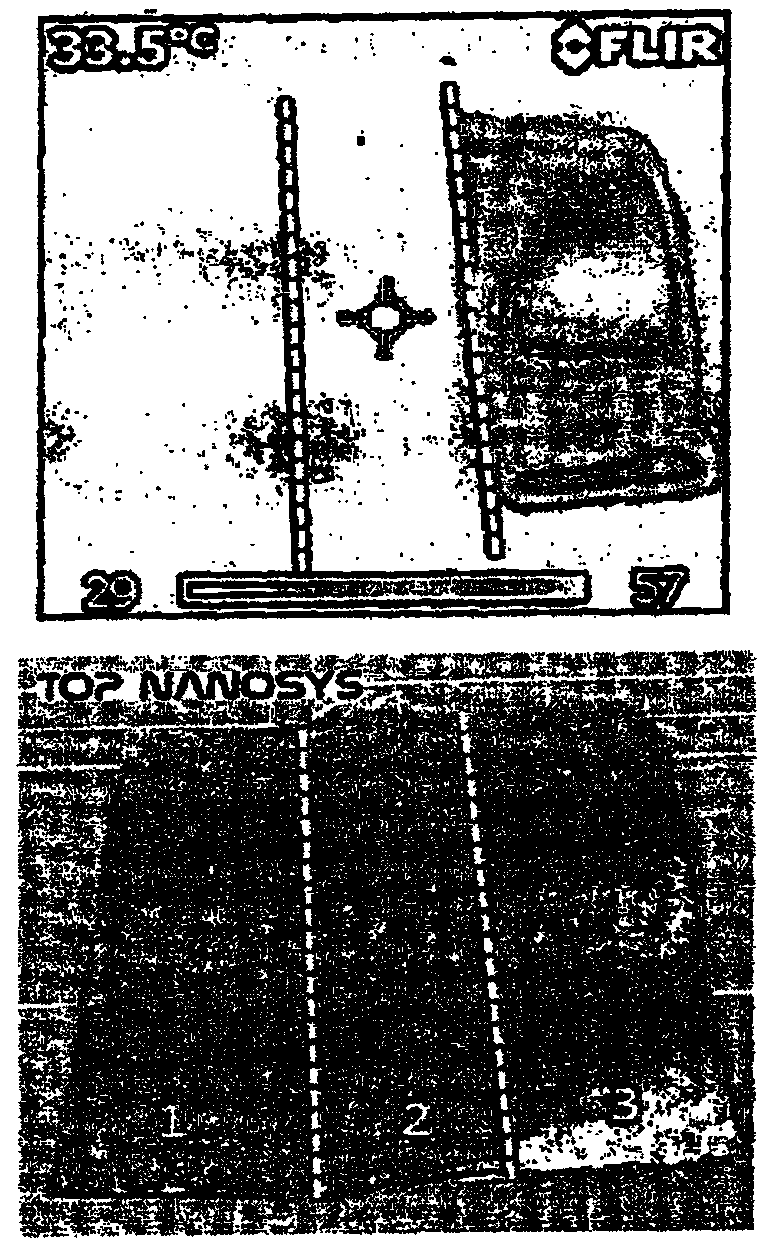

[0056] Such as figure 2 As shown in the lower part of , the carbon nanotube coating liquid prepared by the method of Example 1 above was applied to the No. 1 area of the 10cm×10cm fiber sample, and the thermal storage fabric was prepared according to the same method as Example 1.

Embodiment 3

[0061] In order to prepare carbon nanotubes, a mixed solution of nitric acid and sulfuric acid (3:1) is used to oxidize the surface of single-walled carbon nanotubes prepared by the arc-discharge method to prepare single-walled carbon nanotubes with improved dispersion properties. Tube. 5% by weight of the acid-treated single-walled carbon nanotubes, 5% by weight of a dispersant (trade name: SDS), 0.2% by weight of an antifoaming agent (trade name: Surfynol 104H), and 43.3% by weight of distilled water were mixed, and mixed at 140W (70%) power to apply ultrasound for 1 hour to disperse the carbon nanotubes. 50% by weight of a water-dispersible polyurethane binder (trade name: Sancure 12954) and 1% by weight of a tackifier (trade name: Carbopol EP-1) were mixed in the above dispersion liquid , and stirred in a mixer for 30 minutes to prepare a coating solution. According to the method of Example 1, the coating solution was applied to a 10 cm x 10 cm fiber sample to prepare a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com