High temperature gelatinizing agent used in acidizing and fracturing and synthetic method thereof

A technology of acid fracturing and high-temperature glue, which is applied in the direction of chemical instruments and methods, drilling compositions, etc., which can solve the problems of slowing speed and achieve low residue and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

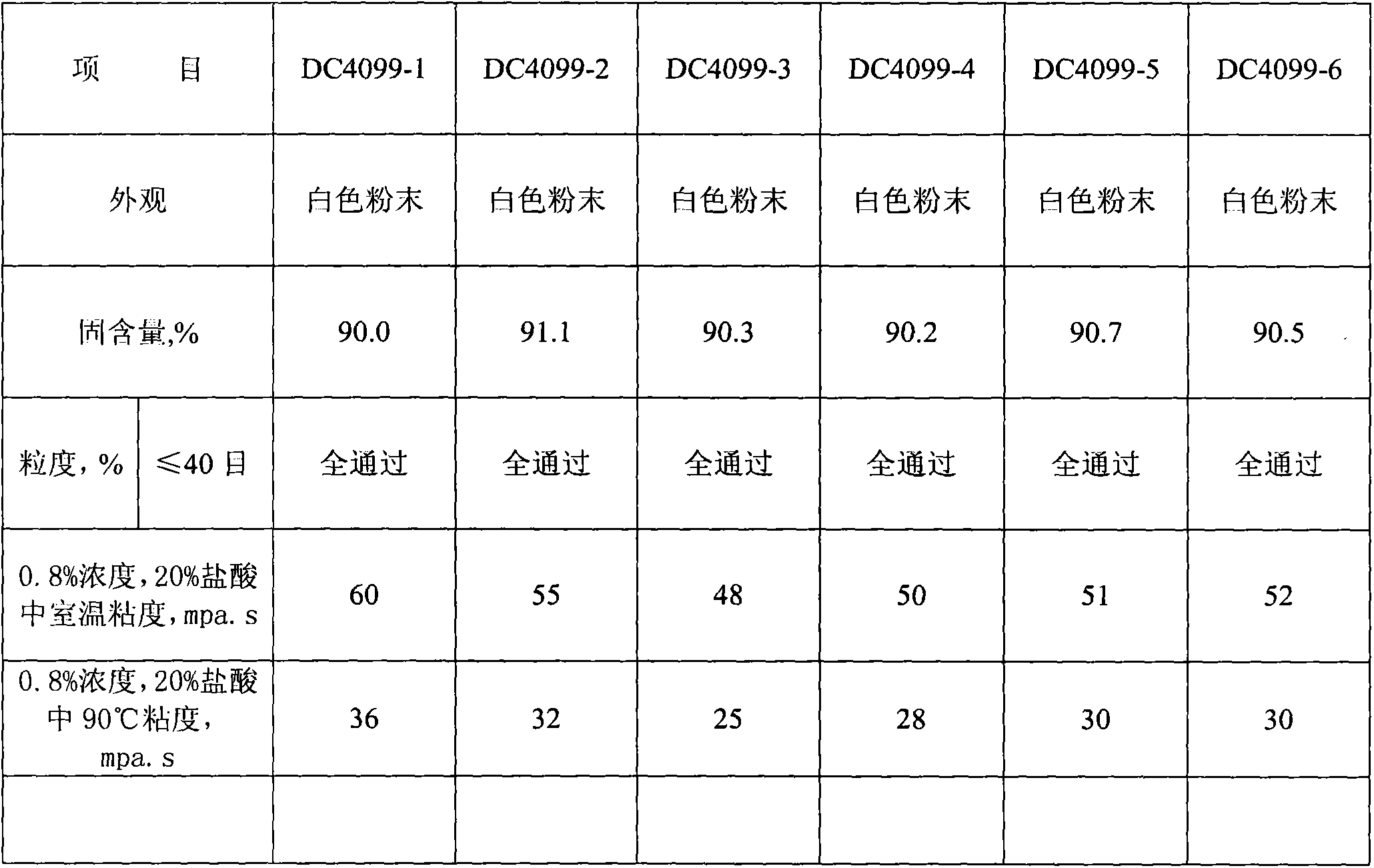

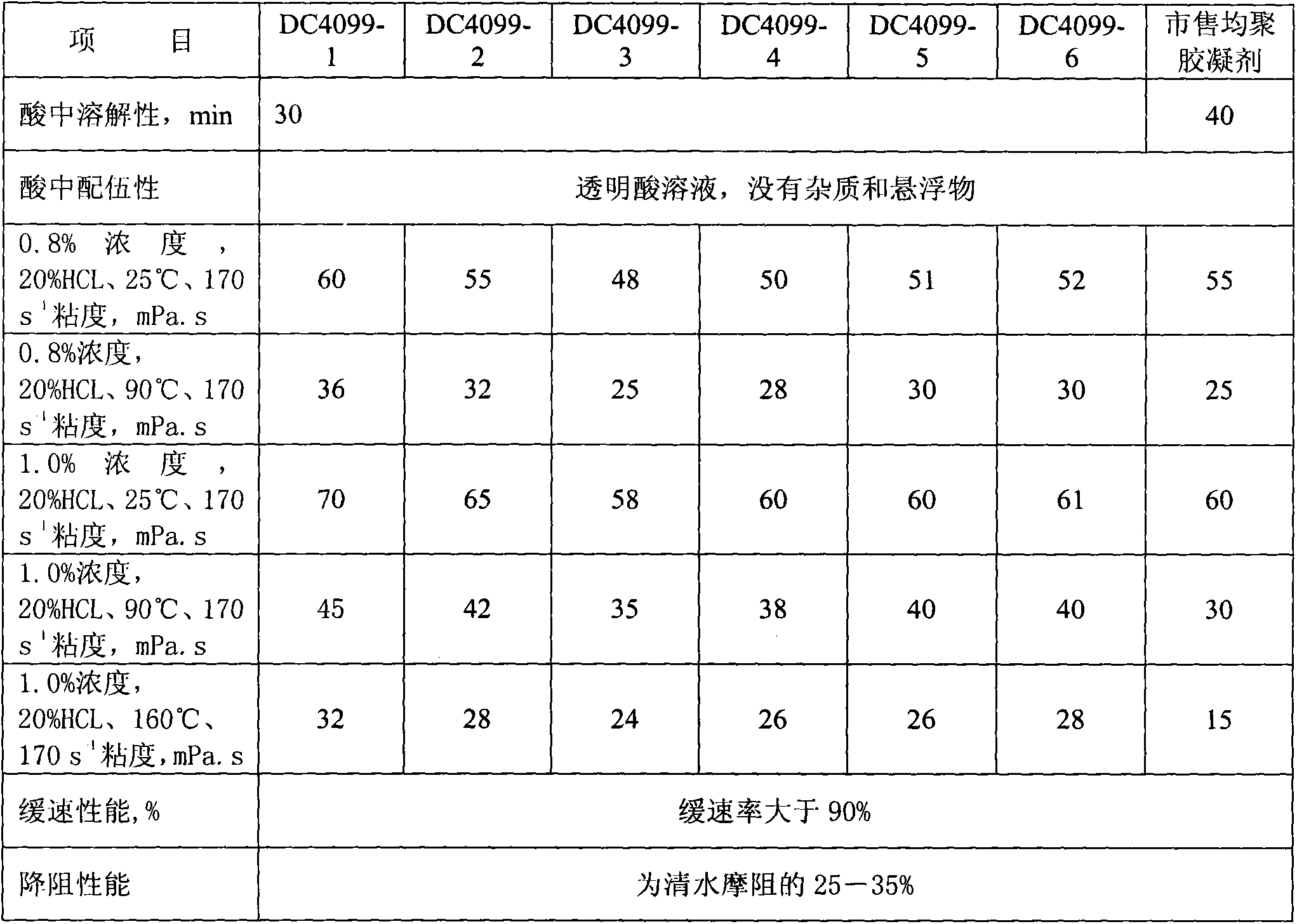

Examples

Embodiment 1

[0040] In this example, the weight percent of each monomer and water is: DMC: DADMAC: AMPS: PVN: H 2 O=30:20:5:5:40.

[0041] Preparation of the solution: add 400g of distilled water in a 2000ml beaker, add 300g of DMC monomer, 200g of DADMAC monomer, add 50g of AMPS monomer, add 50g of PVN monomer, stir and dissolve for 30 minutes, slowly add neutralizer ( sodium hydroxide) to pH 4.5. The stirring solution was continued to ripen for 30 minutes.

[0042] Solution adjustment: according to the pH range after aging, use sodium hydroxide (pH alkaline regulator) or phosphoric acid (pH acidic regulator) to adjust the pH value to 4.5±0.5 again, and adjust the temperature to 10±1°C.

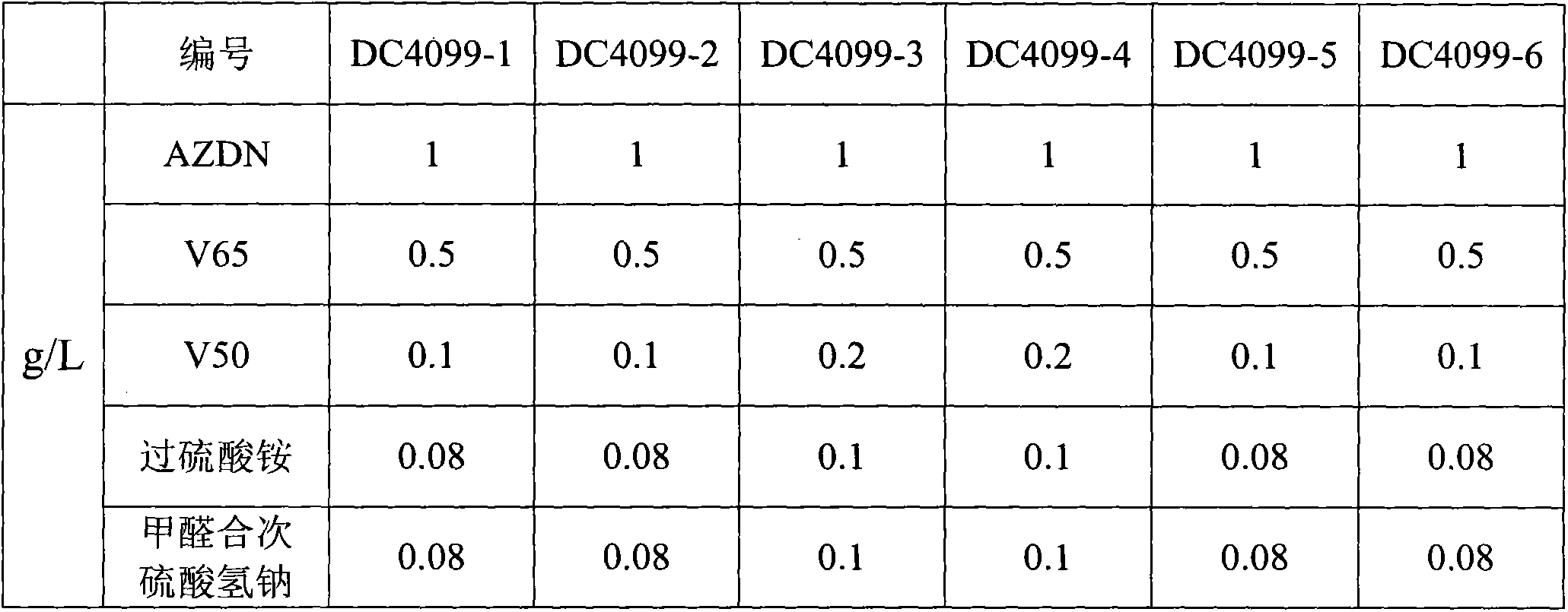

[0043] Polymerization of the solution: Blow nitrogen to remove oxygen for 15-20 minutes, add catalysts AZDN1g / L, V650.5g / L, V500.1g / L, ammonium persulfate 0.08g / L, sodium formaldehyde sulfoxylate in sequence under nitrogen protection 0.08g / L, stop blowing nitrogen and seal the polymerization tank, ind...

Embodiment 2

[0046] In this example, the weight percent of each monomer and water is: DMC: DADMAC: AMPS: PVN: H 2 O=30:20:8:10:32.

[0047] Preparation of the solution: add 320g of distilled water in a 2000ml beaker, add 300g of DMC monomer, 200g of DADMAC monomer, add 80g of AMPS monomer, add 100g of PVN monomer, stir and dissolve for 30 minutes, slowly add neutralizer ( sodium hydroxide) to pH 4.5. The stirring solution was continued to ripen for 30 minutes.

[0048] Solution adjustment: according to the pH range after aging, use sodium hydroxide (pH alkaline regulator) or phosphoric acid (pH acidic regulator) to adjust the pH value to 4.5±0.5 again, and adjust the temperature to 10±1°C.

[0049]Polymerization of the solution: Blow nitrogen to remove oxygen for 15-20 minutes, add catalysts AZDN 1g / L, V650.5g / L, V500.1g / L, ammonium persulfate 0.1g / L, sodium formaldehyde sulfoxylate in sequence under nitrogen protection 0.1g / L, stop blowing nitrogen and seal the polymerization tank, ind...

Embodiment 3

[0052] In this example, the weight percent of each monomer and water is: DMC: DADMAC: AMPS: PVN: H 2 O=20:10:5:5:60.

[0053] Preparation of the solution: add 600g of distilled water in a 2000ml beaker, add 200g of DMC monomer, 100g of DADMAC monomer, add 50g of AMPS monomer, add 50g of PVN monomer, stir and dissolve for 30 minutes, slowly add neutralizer ( sodium hydroxide) to pH 4.5. The stirring solution was continued to ripen for 30 minutes.

[0054] Solution adjustment: according to the pH range after aging, use sodium hydroxide (pH alkaline regulator) or phosphoric acid (pH acidic regulator) to adjust the pH value to 4.5±0.5 again, and adjust the temperature to 10±1°C.

[0055] Polymerization of the solution: Blow nitrogen to remove oxygen for 15-20 minutes, add catalysts AZDN1g / L, V650.5g / L, V500.2g / L, ammonium persulfate 0.1g / L, sodium formaldehyde sulfoxylate in sequence under nitrogen protection 0.1g / L, stop blowing nitrogen and seal the polymerization tank, induc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com