Efficient extraction solvent composition of lignite wax and extraction method of lignite wax

A technology for extracting solvents and compositions, which is applied in the field of high-efficiency extraction solvent compositions and extractions of montan wax, can solve problems such as unsatisfactory economic benefits, low extraction efficiency, and high solvent toxicity, and achieve improved production efficiency and significant economic benefits , the effect of high market value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

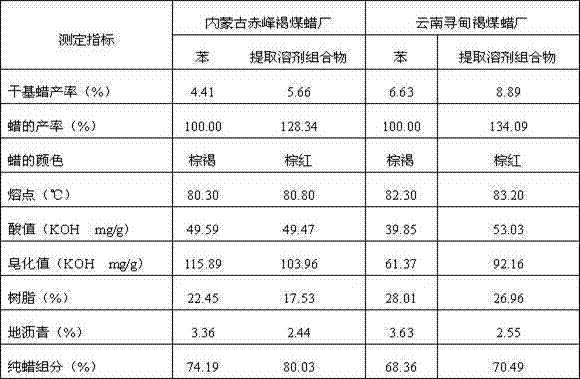

Image

Examples

Embodiment approach

[0016] The mixed extractant includes one or more mixed solvents of esters and aromatic hydrocarbons, cycloalkanes, and linear hydrocarbon solvents, wherein the volume percentage of ester solvents is 10 to 50%, and the balance is aromatic hydrocarbons, cycloalkanes, One or more of straight-chain hydrocarbon solvents, the total amount is 100%.

[0017] The ester solvent is one or more of propyl formate, isopropyl formate, butyl formate, ethyl acetate, n-propyl acetate, isopropyl acetate, isobutyl acetate, and sec-butyl acetate .

[0018] Described aromatic hydrocarbon solvent is benzene and / or toluene; Described cycloalkane solvent is one or more in cyclopentane, cyclohexane, industrial cyclohexane; Described linear hydrocarbon solvent is n-hexane , heptane, octane, industrial hexane, No. 6 solvent oil, No. 120 solvent oil, and light gasoline.

[0019] The surfactant is lipophilic fluorosurfactant.

[0020] The lipophilic fluorine-containing surfactant is one or more of ethyl...

Embodiment 1

[0030] Take a mixed extractant with a volume percentage of 99.95%, and a surfactant ethyl flunonanoate of 0.05%; the volume percentage in the mixed extractant is propyl formate and 90% is benzene.

Embodiment 2

[0032] Take a mixed extractant with a volume percentage of 99.96%, and a surfactant of 0.04% propyl flunonanoate; 20% by volume in the mixed extractant is isopropyl formate and 80% is toluene.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com