Method for preparing special-shaped magnetic core by thermoplastic injection molded iron-based composite materials

An iron-based composite material, injection molding technology, applied in the direction of organic material/organic magnetic material magnetism, inductance/transformer/magnet manufacturing, electrical components, etc., can solve the problem of difficult-to-form magnetic core forming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

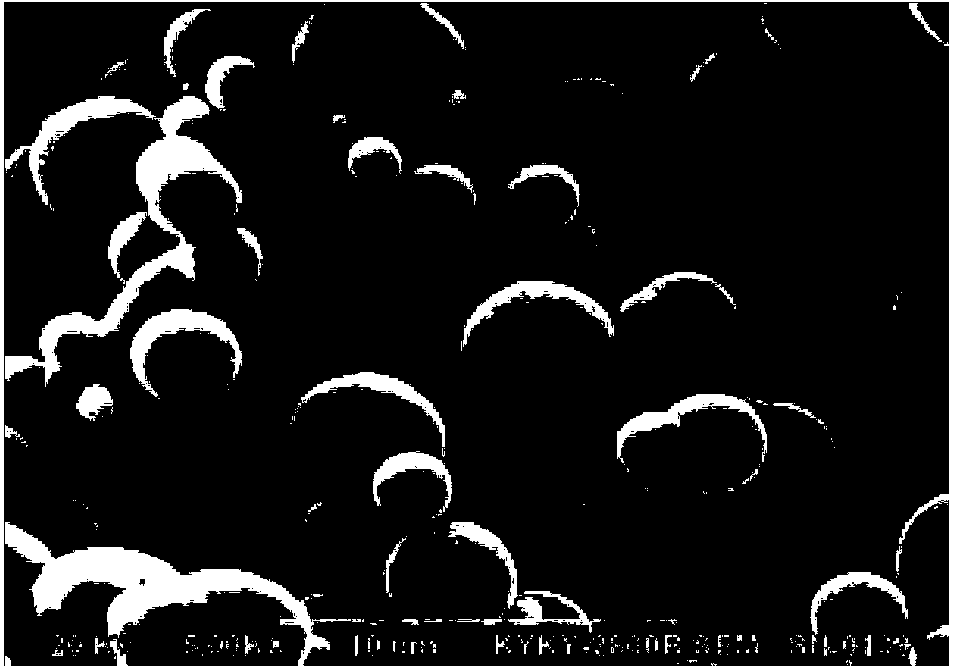

Image

Examples

Embodiment 1

[0014] Embodiment 1: To make a kind of miniature "I" magnetic core, the steps are as follows:

[0015] Step 1: Carbonyl iron phosphide powder [Fe(CO) with a purity of 99.7% 5 ] As the main material, thermoplastic polystyrene (HIPS), phenolic resin (PF), organic chemical benzene (C 6 h 6 ), industrial absolute ethanol with a purity of 99.7% as auxiliary materials, according to the main material carbonyl iron phosphide [Fe(CO) 5 ] accounted for 86% by mass, auxiliary materials thermoplastic polystyrene (HIPS), phenolic resin (PF), organic chemical benzene (C 6 h 6 ) accounted for 12.1%, 1.3%, and 0.6% by mass, mix them, put the mixture in a high-speed mixer at room temperature, stir and mix at a speed of 200 rpm, and then melt at a temperature of 240°C , and then cooled to room temperature in the air, put it into a roller ball mill for grinding, and the grinding balls are steel balls with a volume ratio of ¢3:¢6:¢10 of 1:1:1 to obtain granular isotropic iron-based Composite...

Embodiment 2

[0021] Step 1: Carbonyl iron phosphide powder [Fe(CO) with a purity of 99.7% 5 ] As the main material, thermoplastic polystyrene (HIPS), phenolic resin (PF), organic chemical benzene (C 6 h 6 ), industrial absolute ethanol with a purity of 99.7% as auxiliary materials, according to the main material carbonyl iron phosphide [Fe(CO) 5 ] accounted for 90.8% by mass, auxiliary materials thermoplastic polystyrene (HIPS), phenolic resin (PF), organic chemical benzene (C 6 h 6 ) accounted for 6.8%, 1.72%, and 0.68% by mass, mix them, put the mixture in a high-speed mixer at room temperature and mix it at a speed of 200 rpm, and then melt it at a temperature of 240°C , and then cooled to room temperature in the air, put it into a roller ball mill for grinding, and the grinding balls are steel balls with a volume ratio of ¢3:¢6:¢10 of 1:1:1 to obtain granular isotropic iron-based Composite magnetic materials;

[0022] Step 2: Mix the novolak varnish with brand name X98-11 and indu...

Embodiment 3

[0027] Step 1: Carbonyl iron phosphide powder [Fe(CO) with a purity of 99.7% 5 ] As the main material, thermoplastic polystyrene (HIPS), phenolic resin (PF), organic chemical benzene (C 6 h 6 ), industrial absolute ethanol with a purity of 99.7% as auxiliary materials, according to the main material carbonyl iron phosphide [Fe(CO) 5 ] accounted for 91% by mass, auxiliary materials thermoplastic polystyrene (HIPS), phenolic resin (PF), organic chemical benzene (C 6 h 6 ) accounted for 7.08%, 1.2%, and 0.72% by mass, mix them, put the mixture in a high-speed mixer at room temperature, stir and mix at a speed of 200 rpm, and then melt it at a temperature of 240°C , and then cooled to room temperature in the air, put it into a roller ball mill for grinding, and the grinding balls are steel balls with a volume ratio of ¢3:¢6:¢10 of 1:1:1 to obtain granular isotropic iron-based Composite magnetic materials;

[0028] Step 2: Mix the novolak varnish with brand name X98-11 and ind...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com