Preparation method for anatase type microporous titanium dioxide material for purifying indoor air

A titanium dioxide and anatase type technology, applied in the field of photocatalysis, can solve problems such as poor crystallinity, poor optical activity, and amorphous results, and achieve the effects of large crystallinity, improved adsorption and photocatalytic degradation performance, and reduced indoor health risks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

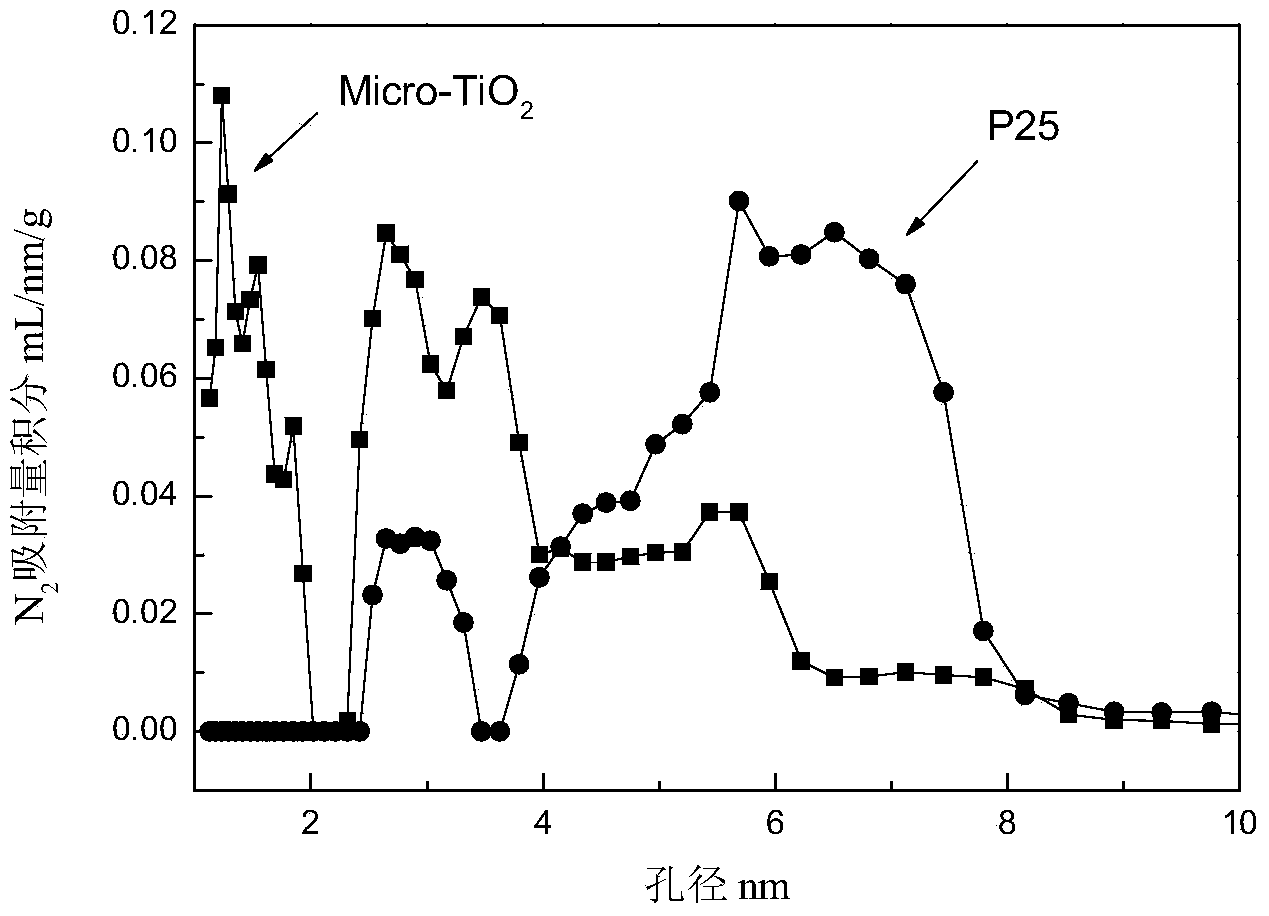

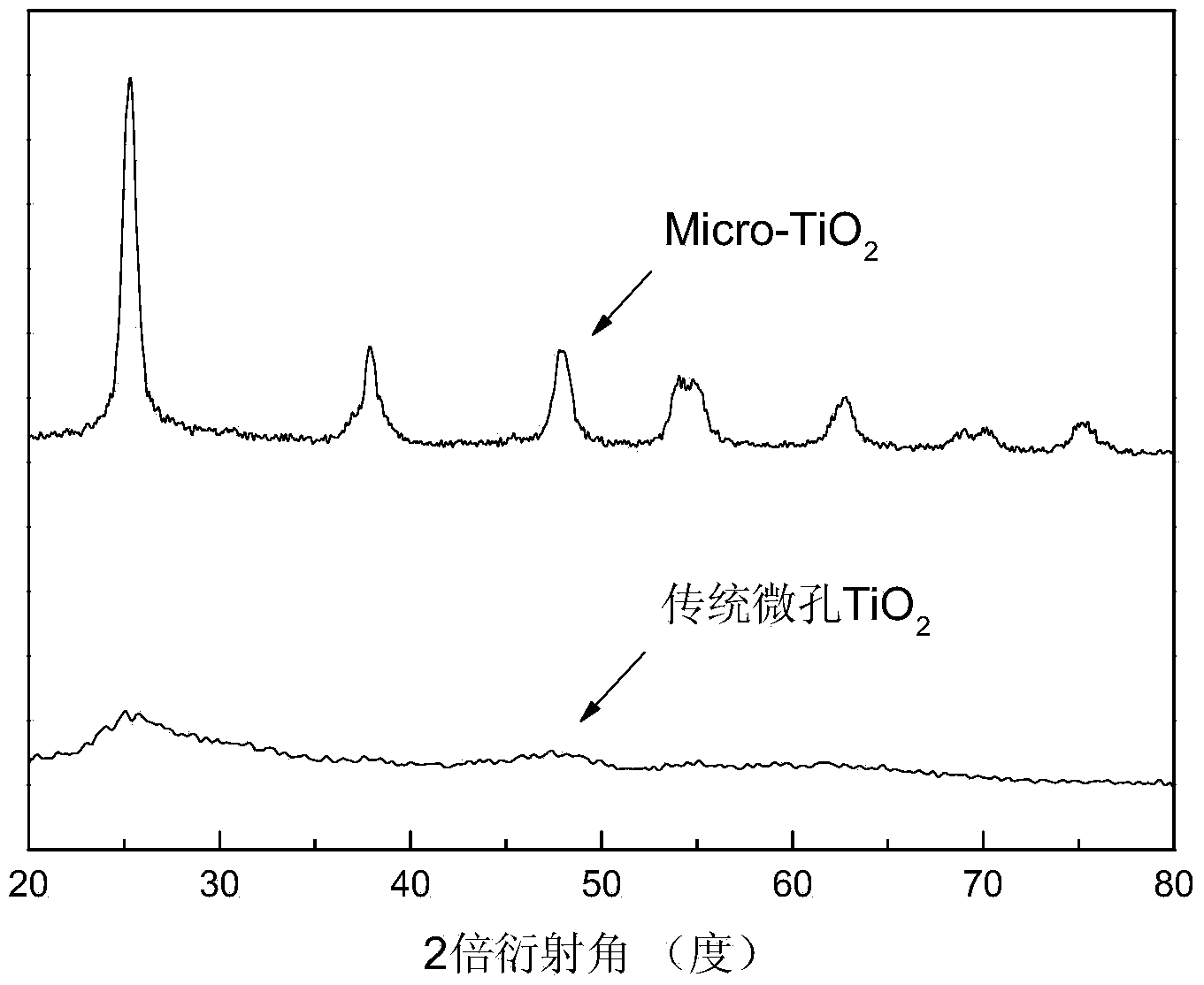

[0024] Dodecylamine was added to absolute ethanol to form a 2 mmol / L ethanol solution of dodecylamine. Butyl titanate was added to the absolute ethanol solution to form a butyl titanate ethanol solution with a concentration of 100 mmol / L. Add 10mL butyl titanate ethanol solution dropwise to 10mL dodecylamine ethanol solution and mix evenly, then add 6.7mL distilled water, stir vigorously for 2 hours at the same time, then add the reaction kettle with PTFE liner, 115 ℃ hydrothermal reaction for 24 hours , naturally cooled and centrifuged. Take 1 g of solid and add it to 100 g of ethanol-hydrochloric acid solution, stir for 1 h, centrifuge, and wash the obtained solid in ethanol-hydrochloric acid solution twice. The solid obtained after centrifugation was washed with water until the pH value was 7, centrifuged, and naturally air-dried to obtain a highly active anatase microporous titanium dioxide material, which was recorded as Micro-TiO 2 .

[0025] Take residence time 0.036...

Embodiment 2

[0030] Dodecylamine was added to absolute ethanol to form a 0.1 mmol / L ethanol solution of dodecylamine. Butyl titanate was added to the absolute ethanol solution to form a butyl titanate ethanol solution with a concentration of 1 mmol / L. Add 10mL of butyl titanate ethanol solution dropwise to 5mL of dodecylamine ethanol solution and mix evenly, then add 2.5mL of distilled water, stir vigorously for 1 hour at the same time, then add to a reaction kettle with a tetrafluoroethylene liner, conduct a hydrothermal reaction at 100°C for 48 hours, and naturally Cool down and centrifuge. Take 1 g of solid and add it to 10 g of ethanol-hydrochloric acid solution, stir for 1 h, centrifuge, and wash the obtained solid in ethanol-hydrochloric acid solution for 3 times. The solid obtained after centrifugation is washed with water until the pH value is 6, centrifuged, and dried to obtain a highly active anatase microporous titanium dioxide material.

Embodiment 3

[0032] Dodecylamine was added to absolute ethanol to form a dodecylamine ethanol solution with a concentration of 6 mmol / L. Butyl titanate was added to the absolute ethanol solution to form a butyl titanate ethanol solution with a concentration of 500 mmol / L. Add 10mL of butyl titanate ethanol solution dropwise to 20mL of dodecylamine ethanol solution and mix evenly, then add 40mL of distilled water, stir vigorously for 3 hours at the same time, then add to the reaction kettle with PTFE liner, conduct hydrothermal reaction at 130°C for 12 hours, and cool down naturally And centrifugal. Take 1 g of solid and add it to 250 g of ethanol-hydrochloric acid solution, stir for 4 hours, centrifuge, and wash the obtained solid in ethanol-hydrochloric acid solution for 4 times. The solid obtained after centrifugation was washed with water until the pH value was 8, centrifuged, and naturally air-dried to obtain a highly active anatase microporous titanium dioxide material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com