Frequency conversion shaker transmission case

A transmission box and box body technology is applied in the field of shaker transmission boxes to achieve the effects of reducing noise, reducing wear and tear of parts and lowering production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

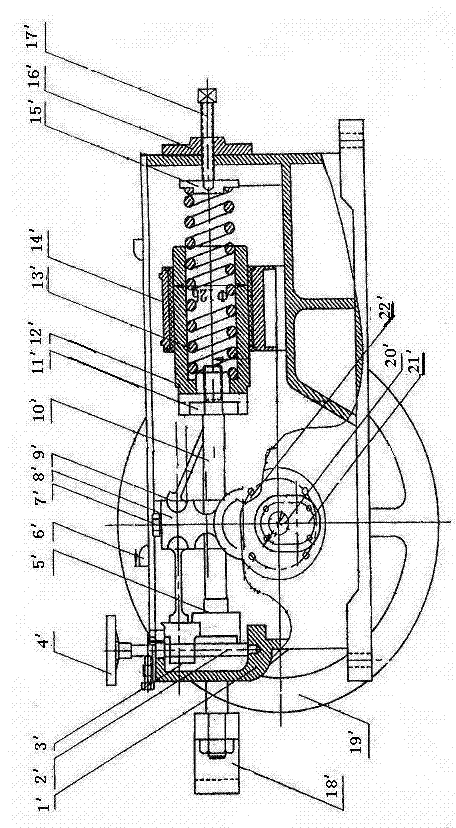

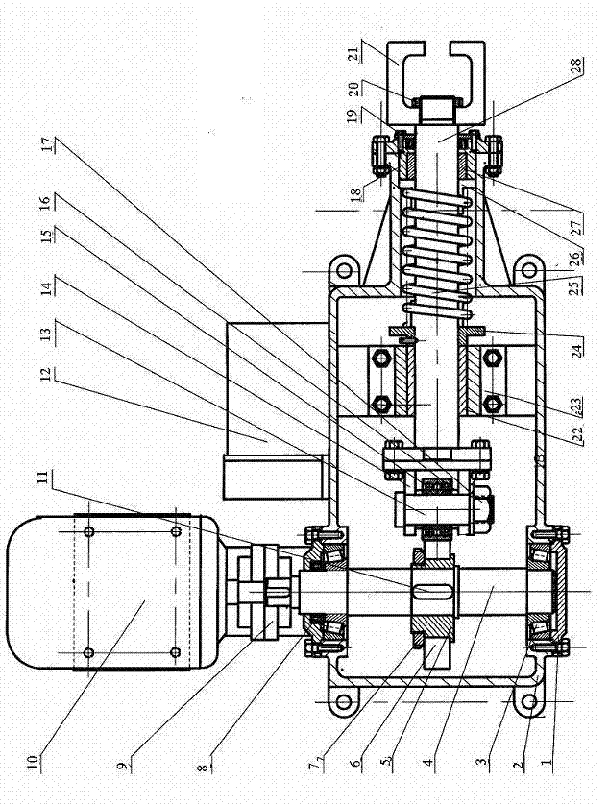

[0028] figure 2 , 3 As shown, the transmission principle of YM-variable frequency shaker transmission box: the eccentric main shaft 4 is directly connected with the motor 10 through the coupling 9, the eccentric main shaft 4 and the eccentric inner sleeve 5 are fixed together, the eccentric cam 6 is set on the eccentric inner sleeve 5, The required stroke can be adjusted by rotating the relative position of the eccentric cam 6 and the eccentric inner sleeve 5. The eccentric cam 6 and the eccentric inner sleeve 5 are marked with corresponding stroke marks. Tighten it so that the eccentric cam 6, the eccentric inner sleeve 5, and the eccentric main shaft 4 are fixed together and rotate at the same time. Since the eccentric cam 4 is always in contact with the rolling bearing 15 on the end face of the reciprocating main shaft 28, with the rotation of the eccentric cam 6, it turns from the lowest point to the highest point, the rolling bearing 15 and the reciprocating main shaft ...

Embodiment 2

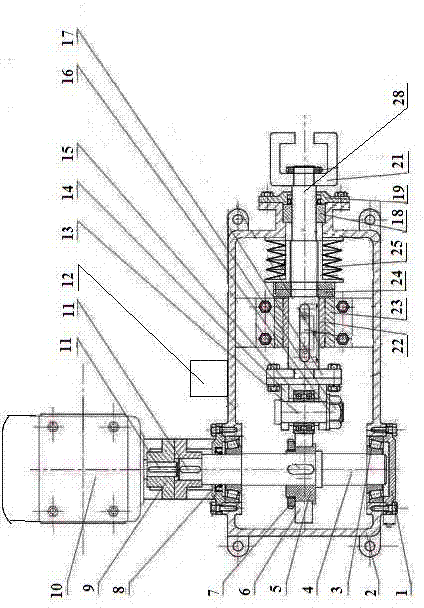

[0031] image 3 , 5 As shown, the spring 25 in the transmission box of the YM-variable frequency shaking table is changed to a butterfly spring, and corresponding improvements are made to the shape of the box and the matching spring support plate 26, positioning copper sleeve 27, and reciprocating main shaft 28 to make the frequency conversion shaking table drive Box, the structure is more compact.

[0032] The start and operation of the YM-variable frequency shaker motor is controlled by a frequency converter, and its motor start is soft start. At present, the way to start the motor is basically a hard start, that is, the power supply directly supplies power to the motor through the switch. Since the motor is in a power failure state, in order To overcome the inertia of the motor rotor, the current in the winding is very large. Under the action of the large current, the motor speed rises rapidly and reaches the rated speed in a short time. At this time, the speed cannot ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com