Common wiring microelectrode array chip and manufacturing method thereof

A micro-electrode array and co-wiring technology, applied in the field of cell micro-electrode array chip and its preparation, can solve the problem of single use, etc., and achieve the effects of excellent conductivity, novel structure and high sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

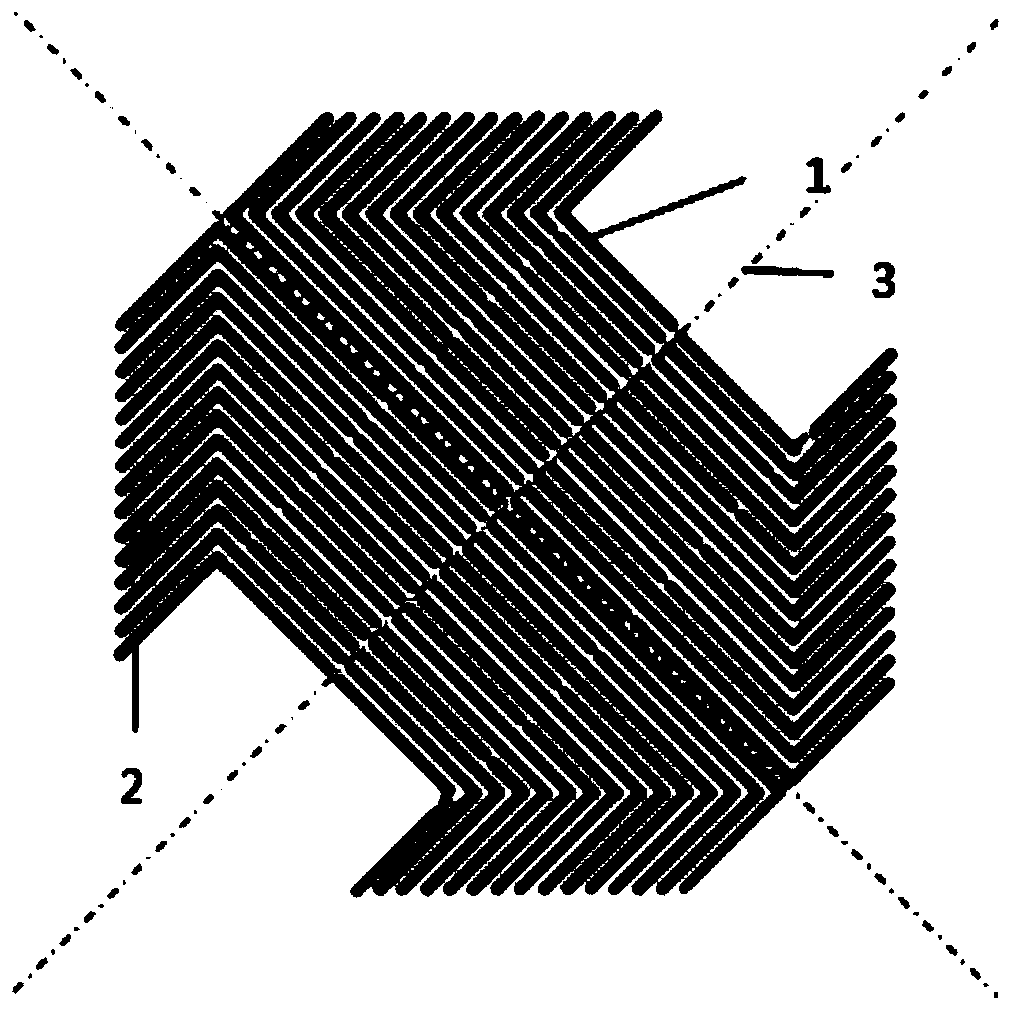

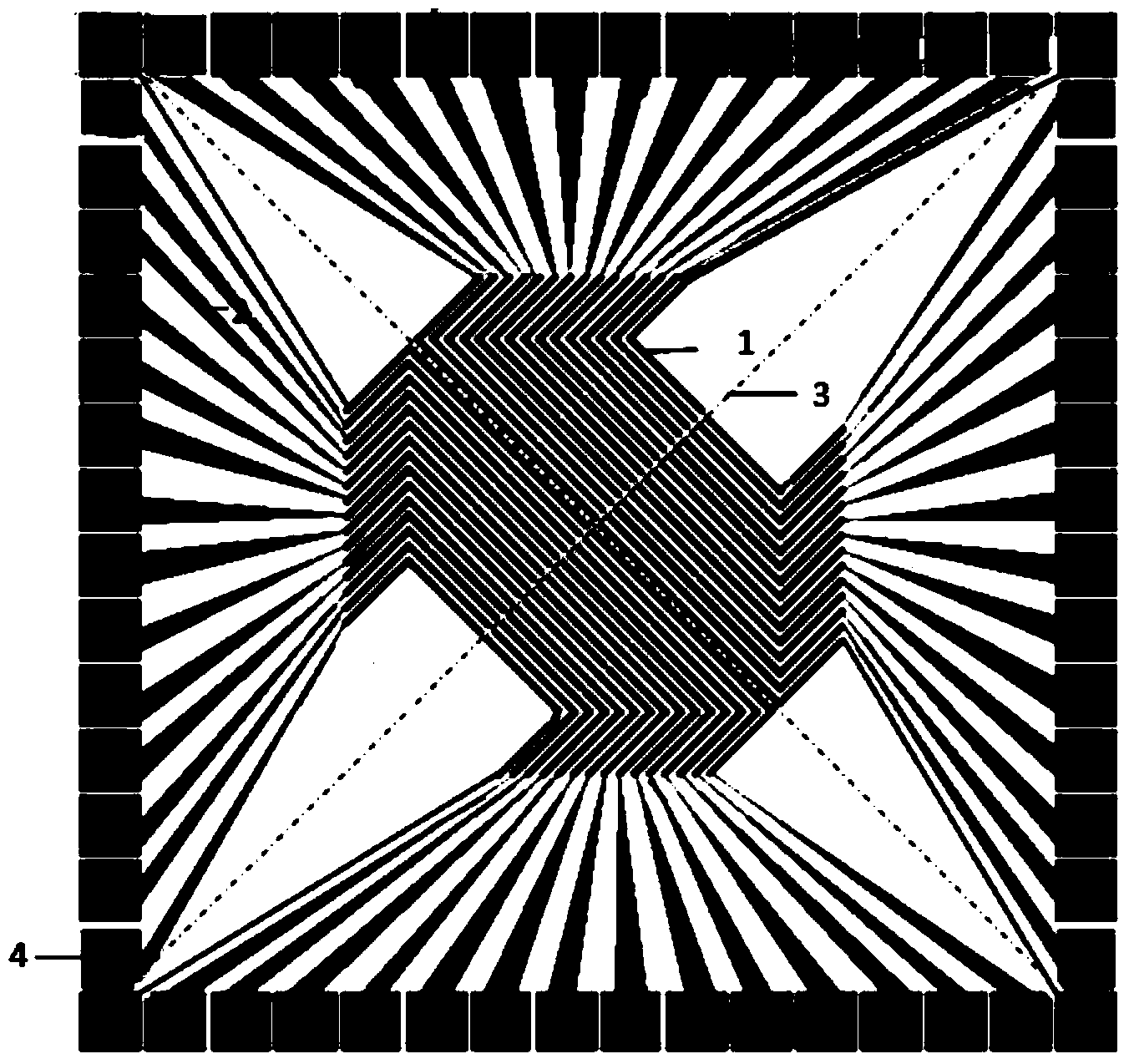

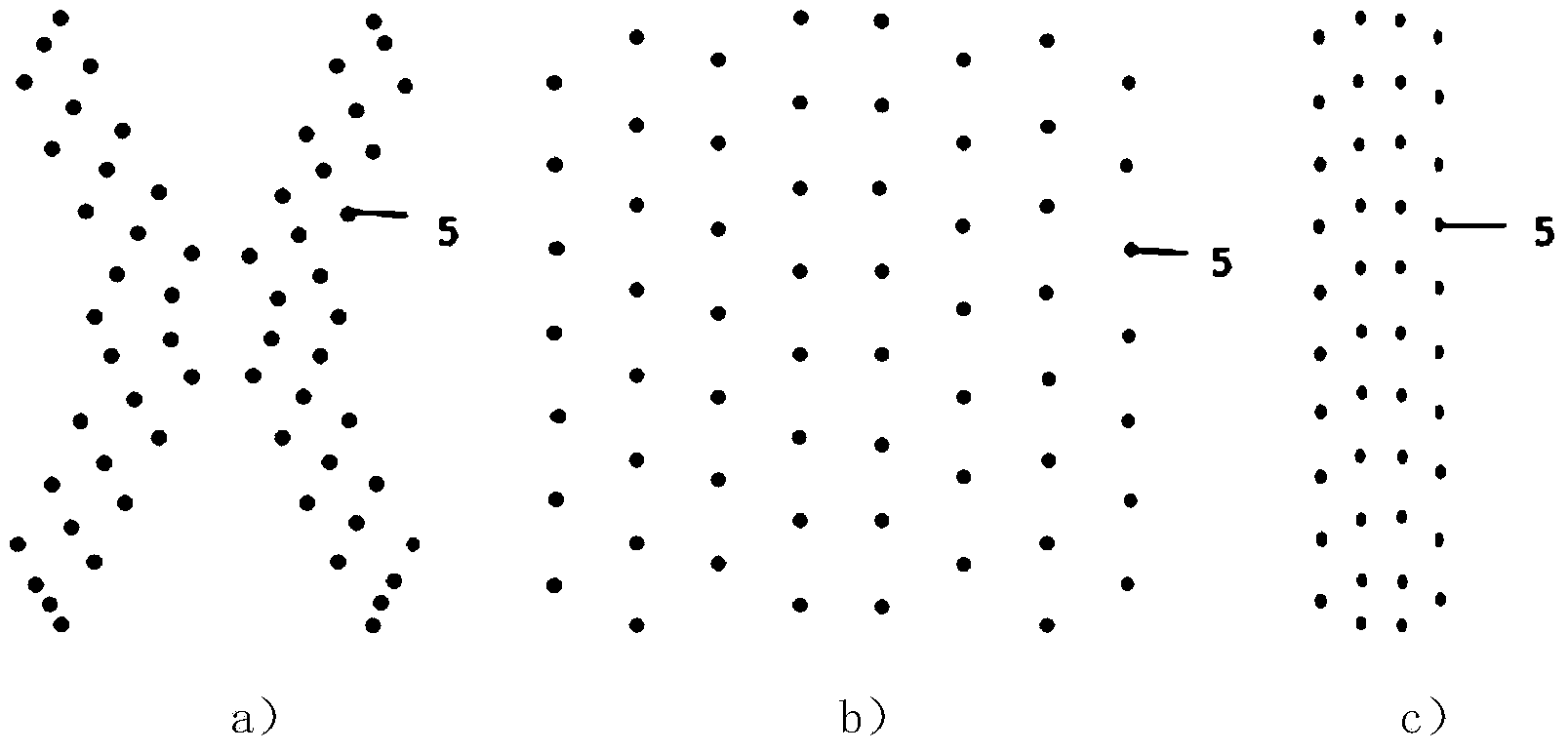

[0034] This embodiment relates to a co-wiring micro-electrode array chip, its structure is as follows Figure 4 As shown, the microelectrode array structure layer on the chip includes a plurality of microelectrodes 1 arranged in a grating array structure and a plurality of microelectrodes 5 arranged in a dot-like array structure superimposed on the grating array.

[0035] The co-wiring microelectrode array chip of this embodiment adopts a new structural design and process, specifically: designing a first mask with a grating array structure and a second mask with a dot matrix array structure in a certain arrangement ; Deposit a layer of metal on the glass substrate, use the first mask, and use photolithography technology to prepare the grating array electrode with the required photoresist structure; use the mask of photoresist and metal, and use ion beam etching technology , open a metal window to obtain a grating electrode array chip; then deposit SiO on the chip in turn 2The...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap