Preparation method for anatase titanium dioxide nanocrystalline mesoporous microsphere

A titanium dioxide, crystal mesoporous technology, applied in the direction of titanium dioxide, chemical instruments and methods, titanium oxide/hydroxide, etc., can solve the problems of using toxic solvents, high energy consumption, complex preparation process, etc., to facilitate separation and low energy consumption , the effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

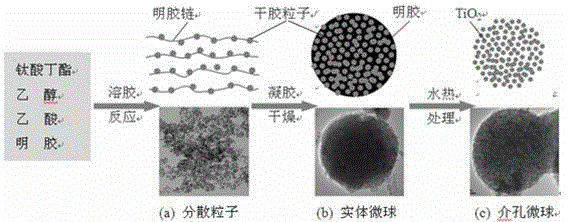

Method used

Image

Examples

Embodiment 1

[0025] a. Using butyl titanate as a raw material and ethanol as a solvent, slowly drop 10ml of butyl titanate into 30ml of ethanol under rapid stirring to prepare a butyl titanate solution;

[0026] b. Dissolving 1g of gelatin in acetic acid to prepare a gelatin solution with a mass concentration of 2%;

[0027] c. Slowly add the above-mentioned gelatin solution to the above-mentioned butyl titanate solution, stir evenly until the solution pH=4, and age the obtained solution at room temperature for 20 hours;

[0028] d. Dry the aged solution in an oven at 55°C to obtain a xerogel;

[0029] e. Boil the dry gel in deionized water for 50 minutes, filter and wash, wash with ethanol three times, and dry naturally in the air to obtain anatase TiO 2 Nanocrystalline mesoporous microspheres.

Embodiment 2

[0031] a. Using butyl titanate as a raw material and methanol as a solvent, slowly drop 10ml of butyl titanate into 50ml of methanol solution under rapid stirring to prepare a butyl titanate solution;

[0032] b. Dissolving 1g of gelatin in acetic acid to prepare a 5% gelatin solution by mass percentage;

[0033] c. Slowly add the above-mentioned gelatin solution to the above-mentioned butyl titanate solution, stir evenly until the solution pH=3, and age the obtained solution at room temperature for 30 hours;

[0034] d. Dry the aged solution in an oven at 50°C to obtain a xerogel;

[0035] e. Boil the dry gel in deionized water for 40 minutes, filter and wash with ethanol for 4 times, and dry naturally in the air to obtain anatase TiO 2 Nanocrystalline mesoporous microspheres.

Embodiment 3

[0037] a. Using butyl titanate as raw material and hexanediol as solvent, slowly drop 10ml butyl titanate into 20ml hexanediol solution under rapid stirring to prepare butyl titanate solution;

[0038] b. Dissolving 1g of gelatin in acetic acid to prepare a gelatin solution with a mass percentage of 3.5%;

[0039] c. Slowly add the above-mentioned gelatin solution to the above-mentioned butyl titanate solution, stir evenly until the solution pH=2, and age the obtained solution at room temperature for 40 hours;

[0040] d. Dry the aged solution in an oven at 45°C to obtain a xerogel;

[0041] e. Boil the dry gel in deionized water for 30 minutes, filter and wash with ethanol for 5 times, and dry naturally in the air to obtain anatase TiO 2 Nanocrystalline mesoporous microspheres.

[0042] Determination example:

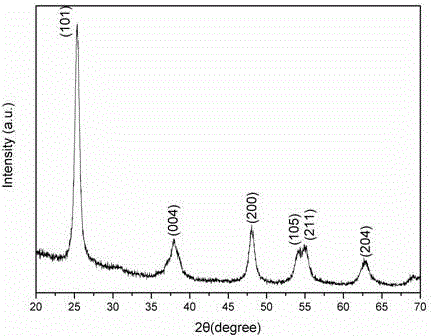

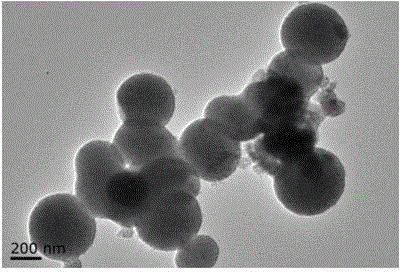

[0043] attached Figure 2-5 is the TiO obtained in Example 2 2 Structure and performance analysis of nanocrystalline mesoporous microspheres.

[0044] figure 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com