Sweep-frequency electronic water treatment system based on single-chip computer

A processing system and single-chip technology, applied in the fields of magnetic field/electric field water/sewage treatment, energy waste water treatment, general control system, etc., can solve the problems of labor-intensive and time-consuming dosing time, reducing the service life of sewage discharge pipes, shortening the service life of materials, etc. , to achieve huge social and economic benefits, low daily operating costs, and stable equipment performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention is described in further detail below with embodiment:

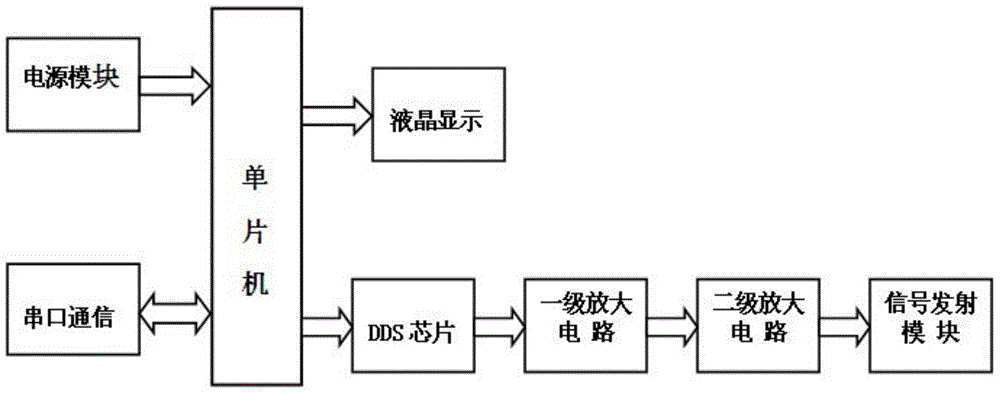

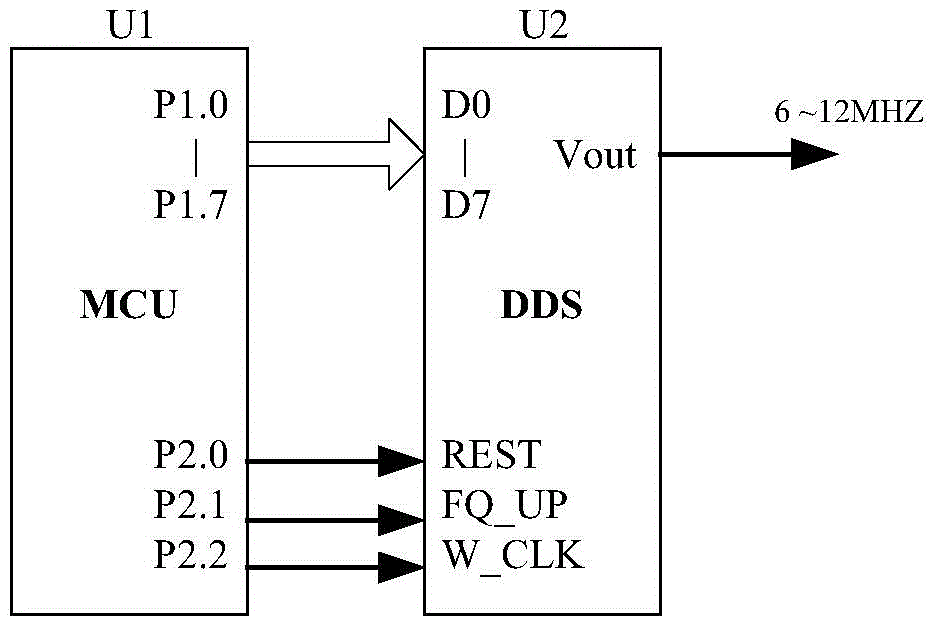

[0034] Such as figure 1 As shown, the present invention includes a power supply module, a single-chip microcomputer, a liquid crystal display module, a digital high-frequency signal generation module (DDS chip), a primary amplifier circuit, a secondary amplifier circuit and a signal transmitting module; a power supply module, a liquid crystal display module and a digital high-frequency The signal generation module (DDS chip) is respectively connected to the single chip microcomputer, and the DDS chip, the primary amplifier circuit, the secondary amplifier circuit and the signal transmitting module are connected in sequence. The single-chip microcomputer controls the DDS chip to generate a sinusoidal signal, and then generates a target signal that meets the requirements through a two-stage amplifying circuit, and finally transmits it into the pipeline through the signal transmitting module. At...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com