Method for ferrum-carbon micro-electrolysis pretreatment of wastewater containing hydrazine and derivatives thereof

A derivative and micro-electrolysis technology, applied in chemical instruments and methods, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve the problem of unindustrialization, low residual concentration of pollutants, difficult to meet Task requirements and other issues, to achieve the effect of promoting electrochemical corrosion, overcoming polarization, and improving the biodegradability of effluent

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

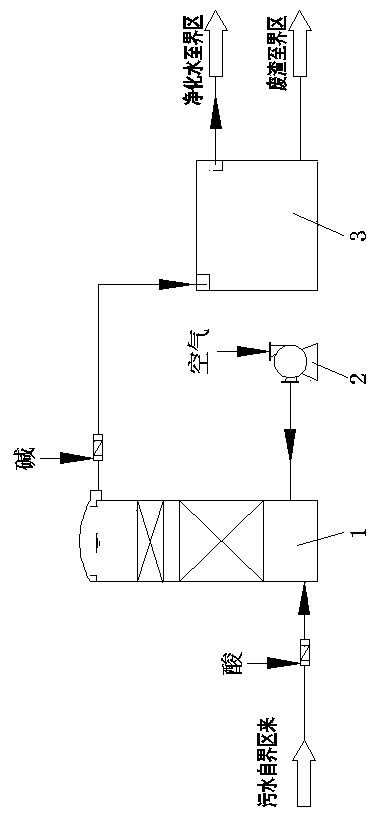

Image

Examples

Embodiment 1

[0016] The water quality of wastewater: the concentration of hydrazine and its derivatives is 970.95mg / L, COD cr 773.65mg / L, pH value is 9.80. According to the above method, the pH value of the hydrazine-containing wastewater and its derivatives is adjusted to 2.10 with dilute sulfuric acid, and then it is passed through the Fe-C micro-particles with cast iron chips and activated carbon powder as fillers in a weight ratio of 9:1. The electrolytic column is fully reacted for 3 hours under the condition of constant air blowing. After treatment, the removal rate of hydrazine and its derivatives in wastewater was 99.72%, COD cr The removal rate was 71.72%, and the pH value was 5.85.

Embodiment 2

[0018] The water quality of wastewater: the concentration of hydrazine and its derivatives is 896.27mg / L, COD cr 758.40mg / L, pH value is 9.95. According to the above method, the pH value of the hydrazine-containing wastewater and its derivatives is adjusted to 2.02 with dilute sulfuric acid, and then it is passed through the Fe-C micro-particles with cast iron chips and activated carbon powder as fillers in a weight ratio of 9:1. The electrolytic column is fully reacted for 2 hours under the condition of constant air blowing. After treatment, the removal rate of hydrazine and its derivatives in wastewater was 94.44%, COD cr The removal rate was 79.01%, and the pH value was 6.24.

Embodiment 3

[0020] The water quality of wastewater: the concentration of hydrazine and its derivatives is 962.66mg / L, and the pH value is 9.68. According to the above method, the pH value of the hydrazine-containing waste water and its derivatives is adjusted to 2.02 with dilute sulfuric acid, and then it is passed through the Fe-C microparticles with iron shavings and activated carbon powder as fillers in a weight ratio of 9:1. The electrolytic column is fully reacted for 9 hours under the condition of constant air blowing. After treatment, the removal rate of hydrazine and its derivatives in the wastewater was over 91%, and the pH value was 5.17.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com