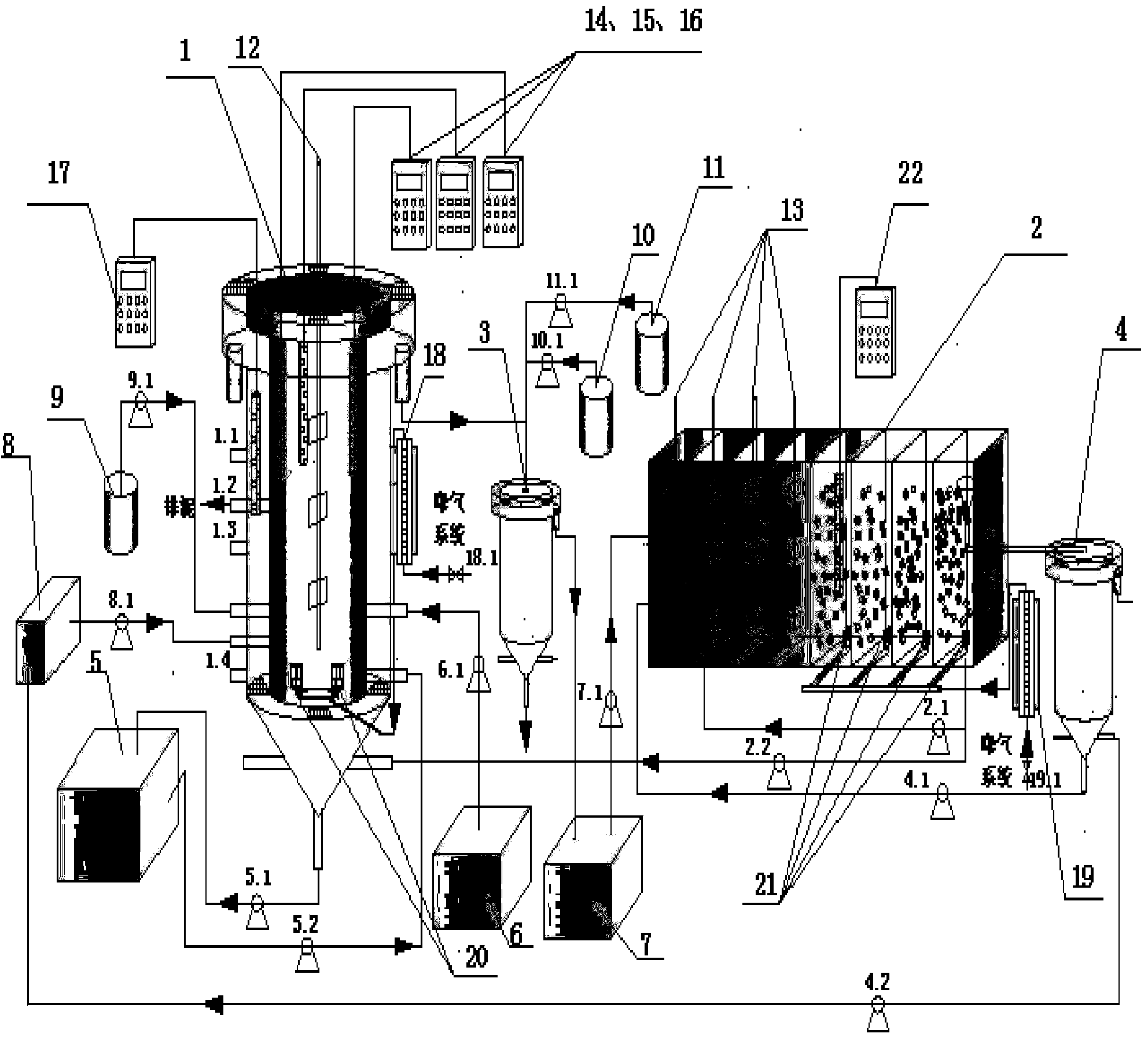

Device and method of residual sludge alkaline fermentation and inner carbon source development technology coupled with A-A-O nitrogen and phosphorous removal system

A technology for excess sludge, nitrogen and phosphorus removal, applied in chemical instruments and methods, water/sludge/sewage treatment, water/sewage multi-stage treatment, etc. Nitrification and denitrification and phosphorus accumulation can not coexist well, so as to solve the emission problem, solve the problem of bacteria and fermentation substrate, and solve the effect of carbon source shortage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example

[0025] The internal reaction zone volume of the anaerobic fermentation integrated equipment is 20L, and the volume of the external sedimentation zone is 75L.

[0026] A-A-O nitrogen and phosphorus removal system volume is 40L, HRT=10h, SRT=15d, A-A-O nitrogen and phosphorus removal system feed water is septic tank sewage in the family area of Beijing University of Technology, and its indicators are SCOD=200-300mg / L, NH 4 -N=55-60mg / L, NO 3 -N=0mg / L, NO 2 -N=0mg / L, PO 4 3- =5-7mg / L.

[0027] 1) Take the SBR pilot sludge as the sludge fermentation device and A-A-O initial start-up sludge, first clean the SBR pilot sludge to remove inorganic particles, SCOD, NH in the sludge 4 -N, NO 3 -N substance. After cleaning, the concentration of sludge in the fermentation unit is MLSS=9000-10000mg / L, SCOD=30-40mg / L, the temperature of the reactor is 20-30℃, and the pH=9-10. A-A-O reactor sludge concentration MLSS=2000-3000mg / L, SCOD=30-40mg / L. The temperature of the A-A-O reactor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com