A kind of extraction method of mycophenolic acid

An extraction method, the technology of mycophenolic acid, applied in the direction of organic chemistry, etc., can solve the problems of increasing production cost, increasing production difficulty, and large loss of mycophenolic acid, and achieves the effect of not being easy to recycle, reducing refining steps, and simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

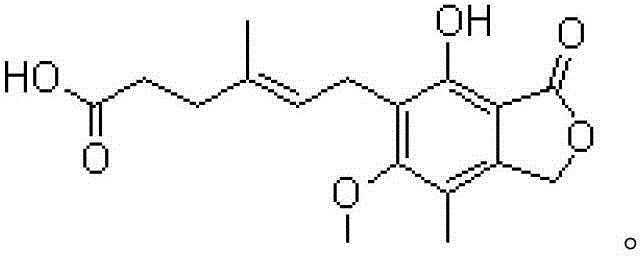

Image

Examples

Embodiment 1

[0070] 10L of mycophenolic acid fermentation broth (fermentation unit: 4978μg / ml) was adjusted to pH 10 with 15% (w / v) NaOH, and filtered. Turn on the stirring, add CaCl of 1% (w / v) of the filtrate volume to the filtrate 2 , adjust the pH to 3.0 with 5mol / L HCl solution, let it settle for 30 minutes, add 20g of perlite filter aid, stir evenly, and filter to obtain a filter cake.

[0071] Dry the filter cake at 40°C, crush the dried 1000g filter cake, put it into the extraction barrel, add 3L butyl acetate, stir and extract at 45°C for about 1 hour, and then use the suction filter to dry the material , to obtain the filtrate. The extraction was repeated 2 more times under the above conditions. Afterwards, the obtained filtrate was concentrated by a thin-film concentrator, the material temperature was 65° C., and the vacuum degree was -0.08 Mpa to obtain 3.1 L of concentrated liquid. Add activated carbon with 2% (w / v) volume of the concentrated solution, and decolorize at 40°...

Embodiment 2

[0075] 10L of mycophenolic acid fermentation broth (fermentation unit: 4898μg / ml) was adjusted to pH 11 with 15% (w / v) NaOH, and filtered. Turn on the stirring, add CaCl of 2% (w / v) of the filtrate volume to the filtrate 2 , adjust the pH to 3.2 with 5mol / L HCl solution, let it settle for 40 minutes, add 20g of perlite filter aid, stir evenly, and filter to obtain a filter cake.

[0076] Dry the filter cake at 42°C, crush the dried 1000g filter cake, put it into the extraction barrel, add 3L butyl acetate, stir and extract at 48°C for 1.5 hours, and then use the suction filter to dry the material. A filtrate was obtained. The extraction was repeated 2 more times under the above conditions. Afterwards, the obtained filtrate was concentrated using a thin-film concentrator, the material temperature was 70° C., and the vacuum degree was -0.08 Mpa to obtain 3.0 L of concentrated liquid. Add activated carbon with 4% volume of the concentrated solution, and decolorize at 45°C for ...

Embodiment 3

[0080]10L of mycophenolic acid fermentation broth (fermentation unit: 7050 μg / mL) was adjusted to pH 12 with 16% (w / v) NaOH, and filtered. Turn on the stirring, add CaCl of 2% (w / v) of the filtrate volume to the filtrate 2 , adjust the pH to 3.5 with 5mol / l HCl solution, let it settle for 50 minutes, add 20g of perlite filter aid, stir evenly, and filter to obtain a filter cake.

[0081] Dry the filter cake at 45°C, crush the dried 1000g filter cake, put it into the extraction barrel, add 3L butyl acetate, stir and extract at 50°C for 2 hours, and then use the suction filter to dry the material. A filtrate was obtained. The extraction was repeated 2 more times under the above conditions. Afterwards, the obtained filtrate was concentrated using a thin film concentrator, the material temperature was 75° C., and the vacuum degree was -0.08 Mpa to obtain 3.5 L of concentrated liquid. Add activated carbon with 5% (w / v) volume of the concentrated solution, and decolorize at 45°C ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com