Synthetic method of resin for hard melamine foam material

A technology of melamine and foaming materials, which is applied in the field of polymer materials, can solve the problems of poor stability of melamine resin, and achieve the effect of preventing the resin from cross-linking too fast, uniform performance, and favorable storage and utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] (1) At pH 9.0 and temperature 80°C, 1 mol of melamine and 2.5 mol of paraformaldehyde undergo methylolation reaction in 6.0 mol of water as solvent for 1.2 hours to generate polyhydroxy melamine;

[0026] (2) Add formic acid to polyhydroxymelamine to adjust the pH to 5.5, then add ethanol, the mass ratio of ethanol to polyhydroxymelamine is 0.02:1, the reaction temperature is 80°C, and the reaction time is 1.0h, a three-dimensional network polymerization reaction occurs, A resin for a rigid melamine foam material was obtained.

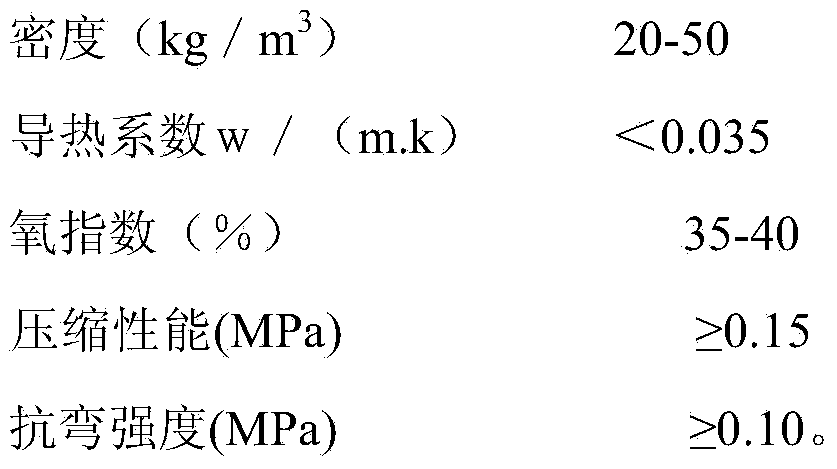

[0027] Add foaming agent, curing agent, and emulsifier to the prepared rigid melamine foaming material resin, wherein the foaming agent, curing agent, and emulsifier are conventional products in the field. foam to obtain a rigid foam material. The performance test is as follows:

[0028]

Embodiment 2

[0030] (1) Under the conditions of pH 8.0 and temperature 85°C, 1 mol of melamine and 1.5 mol of paraformaldehyde undergo a methylolation reaction in 5.5 mol of water as a solvent for 1.5 hours to generate polyhydroxy melamine;

[0031] (2) Add p-toluenesulfonic acid to polyhydroxymelamine to adjust the pH to 6.0, then add polyethylene glycol 400, the mass ratio of polyethylene glycol 400 to polyhydroxymelamine is 0.05:1, the reaction temperature is 90°C, and the reaction time is After 0.8h, a three-dimensional network polymerization reaction occurs to obtain a resin for rigid melamine foaming materials.

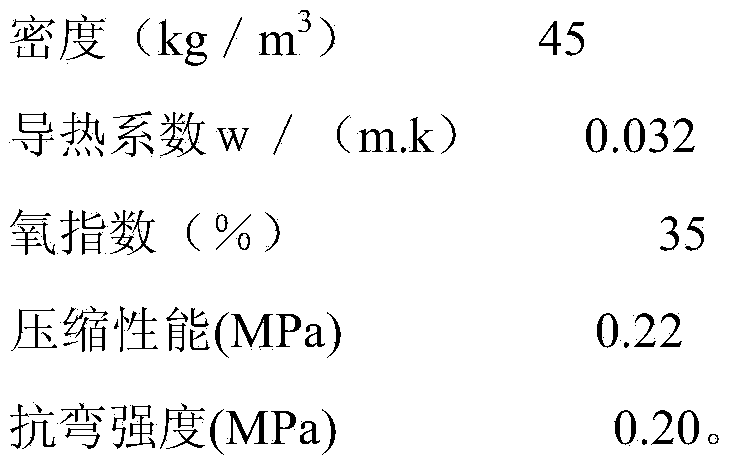

[0032] Add foaming agent, curing agent, and emulsifier to the prepared rigid melamine foaming material resin, wherein the foaming agent, curing agent, and emulsifier are conventional products in the field. foam to obtain a rigid foam material. The performance test is as follows:

[0033]

[0034]

Embodiment 3

[0036] (1) At pH 8.5 and temperature 90°C, 1 mol of melamine and 4.0 mol of paraformaldehyde undergo methylolation reaction in 6.5 mol of water as solvent for 1.8 hours to generate polyhydroxy melamine;

[0037] (2) Add citric acid to polyhydroxymelamine to adjust the pH to 7.0, then add ethylene glycol, the mass ratio of ethylene glycol to polyhydroxymelamine is 0.04:1, the reaction temperature is 85°C, and the reaction time is 1.2h, three-dimensional Reticular polymerization reaction to obtain a resin for rigid melamine foaming materials.

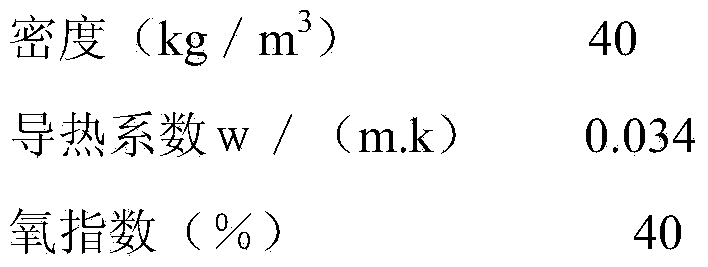

[0038] Add foaming agent, curing agent, and emulsifier to the prepared rigid melamine foaming material resin, wherein the foaming agent, curing agent, and emulsifier are conventional products in the field. foam to obtain a rigid foam material. The performance test is as follows:

[0039]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com