Low-rank coal low-temperature dry distillation pyrolysis process

A low-rank coal and dry distillation technology, applied in the field of coal dry distillation, can solve the problems of high energy consumption, waste of resources, and high pollution emissions, and achieve the effects of reducing environmental pollution and solving dust entrainment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

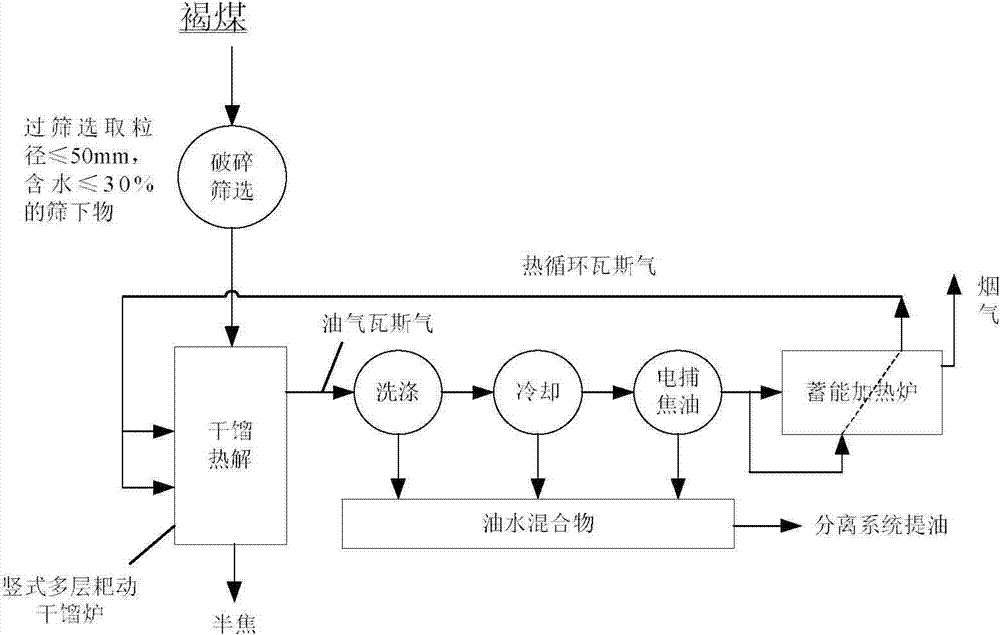

[0029] Combine below figure 1 The present invention will be further described.

[0030] A low-temperature dry distillation pyrolysis process for lignite, comprising the following steps:

[0031] 1. The lignite is dried, crushed and sieved, and the undersized material with a particle size of ≤50 mm and a water content of 30.1% is selected, and sent to the upper hopper of the vertical, multi-layer retort furnace, and enters the drying section through the feeder and the feeding pipe. Under the thrust of the rake teeth in the furnace, it is evenly pushed and turned on each furnace level, and moves down layer by layer, and is combined with the hot oil, gas and gas produced by pyrolysis in the dry distillation section, which passes through the furnace layer of the preheating section and rises to the drying section. The gas is in countercurrent mixed flow contact to complete the drying and dehydration process;

[0032] 2. The dried lignite material enters the preheating section thr...

Embodiment 2

[0038] A low-temperature dry distillation pyrolysis process for lignite, comprising the following steps:

[0039]1. The lignite is dried, crushed and sieved, and the underscreen material with a particle size of ≤50mm and a water content of 18.9% is selected and sent to the hopper above the vertical and multi-layer retort furnace, and enters the drying section through the feeder and the feeding pipeline. Under the thrust of the rake teeth in the furnace, it is evenly pushed and turned on each furnace level, and moves down layer by layer, and is combined with the hot oil, gas and gas produced by pyrolysis in the dry distillation section, which passes through the furnace layer of the preheating section and rises to the drying section. The gas is in countercurrent mixed flow contact to complete the drying and dehydration process;

[0040] 2. The dried lignite material enters the preheating section through the drying section. Under the action of the rake teeth thrust in the furnace...

Embodiment 3

[0046] A long-flame coal low-temperature dry distillation pyrolysis process, comprising the following steps:

[0047] 1. The long-flame coal is dried, crushed and sieved, and the underscreen material with a particle size of ≤50 mm and a water content of 27.6% is selected and sent to the upper hopper of the vertical and multi-layer retort furnace, and enters the drying section through the feeder and the feeding pipeline. Under the thrust of the rake teeth in the furnace, the material is evenly pushed and turned on each furnace level, and moves down layer by layer, and is combined with the heat generated by pyrolysis in the dry distillation section, which passes through the furnace layer of the preheating section and rises to the drying section. The oil, gas and gas are contacted in countercurrent and mixed flow to complete the drying and dehydration process;

[0048] 2. The dry long-flame coal material enters the preheating section through the drying section. Under the thrust o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com