Polycrystalline silicon wafer texturization additive and application thereof

A polycrystalline silicon wafer, additive technology, applied in sustainable manufacturing/processing, crystal growth, final product manufacturing, etc., can solve the problems of poor texturing stability, poor uniformity, large texture size, etc. Sheet efficiency, reduced reflectivity, good uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Apply the texturing process of polycrystalline silicon sheet texturing additive of the present invention, take following process step:

[0023] 1) Preparation of velvet additives: using deionized water as a solvent, dissolve 0.1g of sodium citrate, 0.1g of polyvinyl alcohol, 2g of hydrolyzed polymaleic anhydride, and 0.05g of fluorocarbon surfactant in deionized water to obtain 100g of fleece additives;

[0024] 2) Configure the texturing solution: dissolve 3kg of HF aqueous solution (the mass percentage of HF in the HF aqueous solution is 49%) and 0.05kg of chromium trioxide in deionized water to obtain 10kg of acid solution; then in the acid solution Add 100g of the texturing additive made in step 1) to obtain the texturing liquid;

[0025] 3) Texturing: Dip the polysilicon cell into the texturing solution for surface texturing, the texturing temperature is 10°C, and the texturing time is 1200s.

Embodiment 2

[0027] Apply the texturing process of polycrystalline silicon sheet texturing additive of the present invention, take following process step:

[0028] 1) Preparation of texturing additives: using deionized water as a solvent, dissolve 2g of sodium citrate, 2g of polyvinyl alcohol, 20g of hydrolyzed polymaleic anhydride, and 0.32g of fluorocarbon surfactant in deionized water to obtain 400g of texturing additives ;

[0029] 2) Configure the texturing solution: dissolve 6kg of HF aqueous solution (the mass percentage of HF in the HF aqueous solution is 49%) and 0.2kg of chromium trioxide in deionized water to obtain 10kg of acid solution; then in the acid solution Add 400g of the texturing additive made in step 1) to obtain the texturing liquid;

[0030] 3) Texturing: Dip the polysilicon cell into the texturing solution for surface texturing, the texturing temperature is 30°C, and the texturing time is 300s.

Embodiment 3

[0032] Apply the texturing process of polycrystalline silicon sheet texturing additive of the present invention, take following process step:

[0033] 1) Preparation of velvet additives: using deionized water as a solvent, dissolve 0.6g sodium citrate, 0.6g polyvinyl alcohol, 7g hydrolyzed polymaleic anhydride, and 0.13g fluorocarbon surfactant in deionized water to obtain 200g of fleece additives;

[0034] 2) Configure the texturing solution: dissolve 4.5kg of HF aqueous solution (the mass percentage of HF in the HF aqueous solution is 49%) and 0.125kg of chromium trioxide in deionized water to obtain 10kg of acid solution; Add 200g of the texturing additive made in step 1) to the solution to obtain the texturing liquid;

[0035] 3) Texturing: Dip the polysilicon cell into the texturing solution for surface texturing, the texturing temperature is 20°C, and the texturing time is 750s.

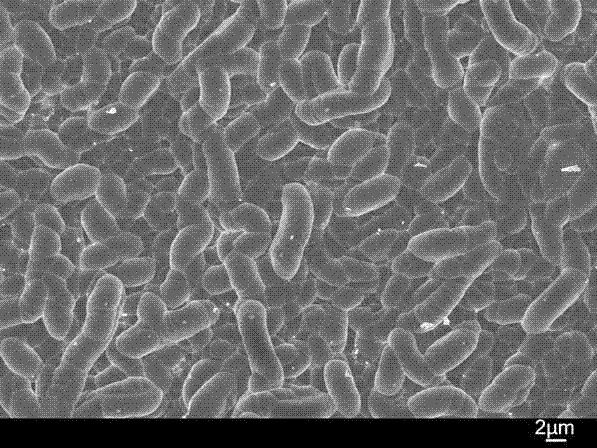

[0036] figure 1 It is the scanning electron micrograph of the suede surface of the polyc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com