Liquid crystal display and manufacturing method thereof

A liquid crystal display and liquid crystal technology, applied in the direction of instruments, nonlinear optics, optics, etc., can solve problems such as high cost of glass substrates, lack of strokes on display, hidden dangers of electrical corrosion, etc., to prevent electrical corrosion, improve display uniformity, and improve The effect of the overall stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

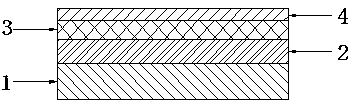

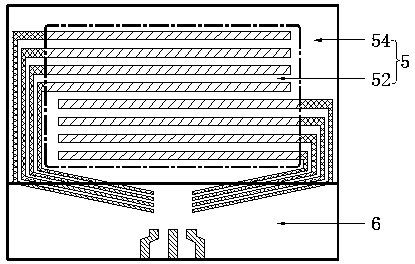

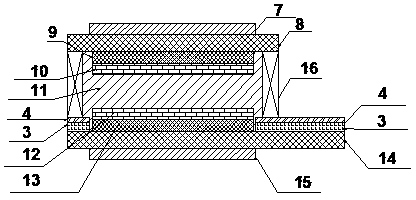

[0039] Embodiment 1: as Figure 1-3 The liquid crystal display shown comprises the liquid crystal box viewing area 5, the terminal lead area 6 and the metal layer outside the liquid crystal box. The viewing area 54 in the liquid crystal cell; the viewing area 5 of the liquid crystal cell is a composite layer structure, which successively includes a front polarizer 7, a front transparent glass substrate 8, a front insulating layer 9, a front vertical alignment layer, a liquid crystal layer 11, and a rear vertical alignment layer , a rear insulating layer 13, a rear transparent glass substrate 14 and a rear polarizer 15, the liquid crystal layer 11 is surrounded by a frame glue 16; one end of the rear transparent glass substrate 14 is flush with the front transparent glass substrate 8, and the other end is longer than the front transparent glass substrate 8 Transparent glass substrate 8, the outer terminal lead area 6 of the liquid crystal cell is the part where the rear transpa...

Embodiment 2

[0050] Embodiment 2: as Figure 4 Shown, substantially the same as embodiment 1, difference is: make nickel-plated layer 3 and gold-plated layer 4 in liquid crystal box internal viewing area 54, adopt the thickness of nickel-plated layer 3 to be 2.0 micron, adopt the thickness of gold-plated layer 4 to be 0.15 microns, the square resistance value of the glass substrate is reduced to 0.2 Ω / sq, and then the parallel alignment layers 10' and 12' are selected, and the thickness of the liquid crystal layer 11 is set to 6 microns, and the Δn is 0.145 positive liquid crystals, and the diameter of 6 microns is selected For plastic balls, set the twist angle formed by front and rear friction to 240°, and select SMD-570TA and QPF-205TF2 at the same time.

Embodiment 3

[0051] Embodiment 3: as Figure 5 As shown, it is basically the same as in Embodiment 1, and the difference is that a nickel-plated layer 3 and a gold-plated layer 4 are made in the terminal lead area 6 outside the liquid crystal cell, and the thickness of the nickel-plated layer 3 is 2.0 microns, and the thickness of the gold-plated layer 4 is adopted. 0.15 microns, the square resistance value of the glass substrate is reduced to 0.3 Ω / sq, select parallel alignment layers 10', 12', set the liquid crystal layer 11 to be a positive liquid crystal with a thickness of 7 microns and Δn of 0.15, and select a 7 micron diameter For plastic balls, set the twist angle formed by front and rear friction to 90°, and select QPF-215T and QPF-215T at the same time.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com