Schottky diode chip, Schottky diode device and manufacturing method for Schottky diode chip-composite barrier

A technology of Schottky diodes and chips, which is applied in the direction of diodes, semiconductor/solid-state device manufacturing, semiconductor devices, etc., can solve the problems of inability to effectively adjust the barrier height, reduce the fatigue resistance of devices, and weak barrier diffusion, and meet the requirements of High temperature performance, improved fatigue resistance, and low cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

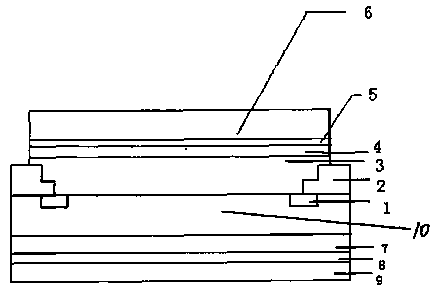

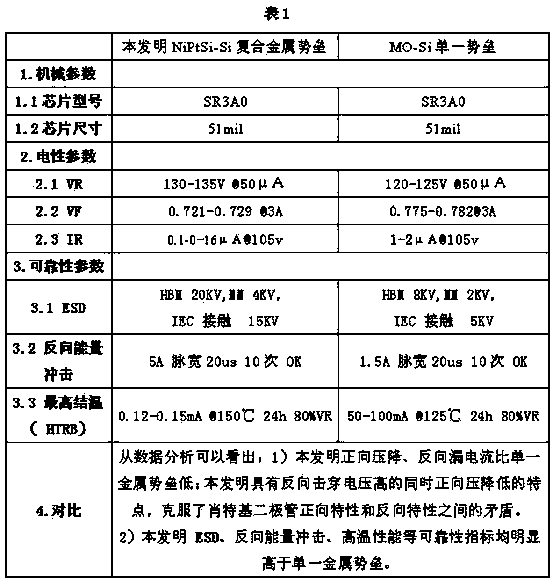

[0045] The power Schottky device of the present invention such as figure 1 As shown, there is a semiconductor substrate 10, the substrate is an N-type silicon chip, and the front side of the semiconductor substrate is provided with a silicon dioxide oxide layer 2, and the middle part of the oxide layer has a window, and the longitudinal section of the window is T shape, so that the side of the oxide layer with a window is stepped, and a barrier layer 3 is provided in the window. The barrier layer covers the mesa of the oxide layer and extends to the highest surface of the oxide layer. The material of the barrier layer is NiPtSi , the potential barrier layer is in direct contact with the semiconductor substrate to form a NiPtSi-Si potential barrier, the front multilayer metal electrode is arranged on the potential barrier layer, and the back multilayer metal electrode is arranged on the back of the semiconductor substrate. A guard ring 1 is also provided in the semiconductor s...

Embodiment 2

[0052] The preparation method of the power Schottky device composite barrier of the present invention comprises the following steps:

[0053] (1) Oxidation: Oxidize the silicon wafer to form an oxide layer SiO2 on its surface;

[0054] (2) Perform a photolithography on the silicon wafer to form an annular groove window on the oxide layer. The longitudinal section of the window is T-shaped. The surface of the oxide layer after photolithography is flat. , the height of the mesa is lower than the height of the surface of the oxide layer, so that the window side of the oxide layer annular groove has a stepped edge;

[0055] (3) Boron diffusion: the boron diffusion method of solid flake BN is used to make a protective ring on the silicon wafer;

[0056] (4) Main diffusion: Use a high temperature of 1100°C to carry out deep advancement of the guard ring junction, and the time is about 1h;

[0057] (5) Carry out secondary photolithography to form barrier region windows;

[0058] (...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com