Organic/nano-sodium tantalate composite sun-blind ultraviolet light detector

A solar-blind, nano-tantalum technology, applied in the field of detectors, can solve the problems of unfavorable devices working for a long time, increase the contact probability, etc., to achieve the effect of selective response and avoid interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

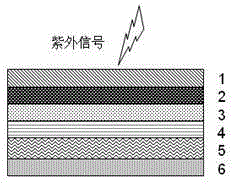

Embodiment 1

[0021] The quartz substrate was ultrasonically washed with detergent, isopropanol, ethanol, and acetone for 5 minutes, rinsed with deionized water and dried. Vacuum-deposit a layer of 2nm-thick metal aluminum on the quartz substrate, and after UV-ozone treatment, prepare a PEDOT:PSS (polyaniline derivative) electrode modification layer with a thickness of about 40nm by spin coating, and bake at 120°C. Remove after 15 minutes of baking. Choose D (n = 1) as the donor material, and sodium tantalate (particle size 3 nm) as the acceptor material A. First prepare D with a thickness of about 30nm by spin coating on PEDOT:PSS, and then prepare A with a thickness of about 20nm by solution spin coating on the D film. The above two layers constitute an organic-inorganic composite with a planar heterojunction structure. active layer. Finally, 1nm thick LiF and 100nm thick aluminum electrodes were sequentially prepared by vacuum evaporation. As mentioned above, get as figure 1 The orga...

Embodiment 2

[0023] The quartz substrate was ultrasonically washed with detergent, isopropanol, ethanol, and acetone for 5 minutes, rinsed with deionized water and dried. Vacuum-deposit a layer of metallic silver with a thickness of 20nm on the quartz substrate, and after UV-ozone treatment, prepare a PEDOT:PSS (polyaniline derivative) electrode transport layer with a thickness of about 40nm by spin coating, and bake at 120°C Remove after 15 minutes of baking. Choose D (n = 2) as the donor material, and sodium tantalate (particle size 30 nm) as the acceptor material A. A mixed film with a thickness of about 70nm was prepared by solution spin coating on PEDOT:PSS. The weight ratio of donor material D:acceptor material A in the mixed film was 95:5, forming an organic-inorganic structure with a bulk heterojunction structure. Composite active layer. Finally, 1nm thick LiF and 200nm silver electrodes were sequentially prepared by vacuum evaporation method. As mentioned above, get as figure ...

Embodiment 3

[0025] The quartz substrate was ultrasonically washed with detergent, isopropanol, ethanol, and acetone for 5 minutes, rinsed with deionized water and dried. Vacuum-deposit a layer of silver / aluminum mixture with a thickness of 15nm on the quartz substrate, and after UV-ozone treatment, prepare a PEDOT:PSS (polyaniline derivative) electrode modification layer with a thickness of about 40nm by spin coating, at 120°C Remove from the oven after 15 minutes. Choose D (n = 3) as the donor material, and sodium tantalate (particle size 10 nm) as the acceptor material A. First prepare D with a thickness of about 30nm on PEDOT:PSS by vacuum evaporation, and then prepare A with a thickness of about 30nm on the D film by solution spin coating. - Inorganic composite active layer. Finally, 1nm thick LiF and 300nm gold electrodes were sequentially prepared by vacuum evaporation. As mentioned above, get as figure 1 The organic / nano-sodium tantalate composite sun-blind UV photodetector sho...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com