Electrocatalyst of negative electrode of fuel cell as well as preparation method and application thereof

A fuel cell cathode, electrocatalyst technology, applied in battery electrodes, physical/chemical process catalysts, chemical instruments and methods, etc., can solve problems such as performance attenuation, achieve low cost, improve durability, and increase the effect of diversification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] The now configured aniline hydrochloride solution (5mL aniline+3mL 37.5%HCl+14mL H 2 O) 10 mL. After stirring for 30 minutes, 1mol / L HCl solution was added dropwise to adjust the pH of the solution to 3.0. After 1 h of reaction, 25 mL of 0.5 mol / L (NH 4 ) 2 S 2 o 8 The solution was slowly dropped into the above solution, phenylphosphine was added thereto, the molar ratio of N:P was 10:1, and then 0.36g Co(NO 3 ) 2 ·6H 2 O, after stirring evenly, polymerize at room temperature for 12 hours, evaporate to dryness, wash, and dry at 85°C, then treat it in an ammonia atmosphere at 900°C for 3 hours to obtain a black powder; then use a ball mill for 3 hours to obtain Phosphorus and boron co-doped nanocarbon electrocatalysts with ordered nanostructures.

Embodiment 2

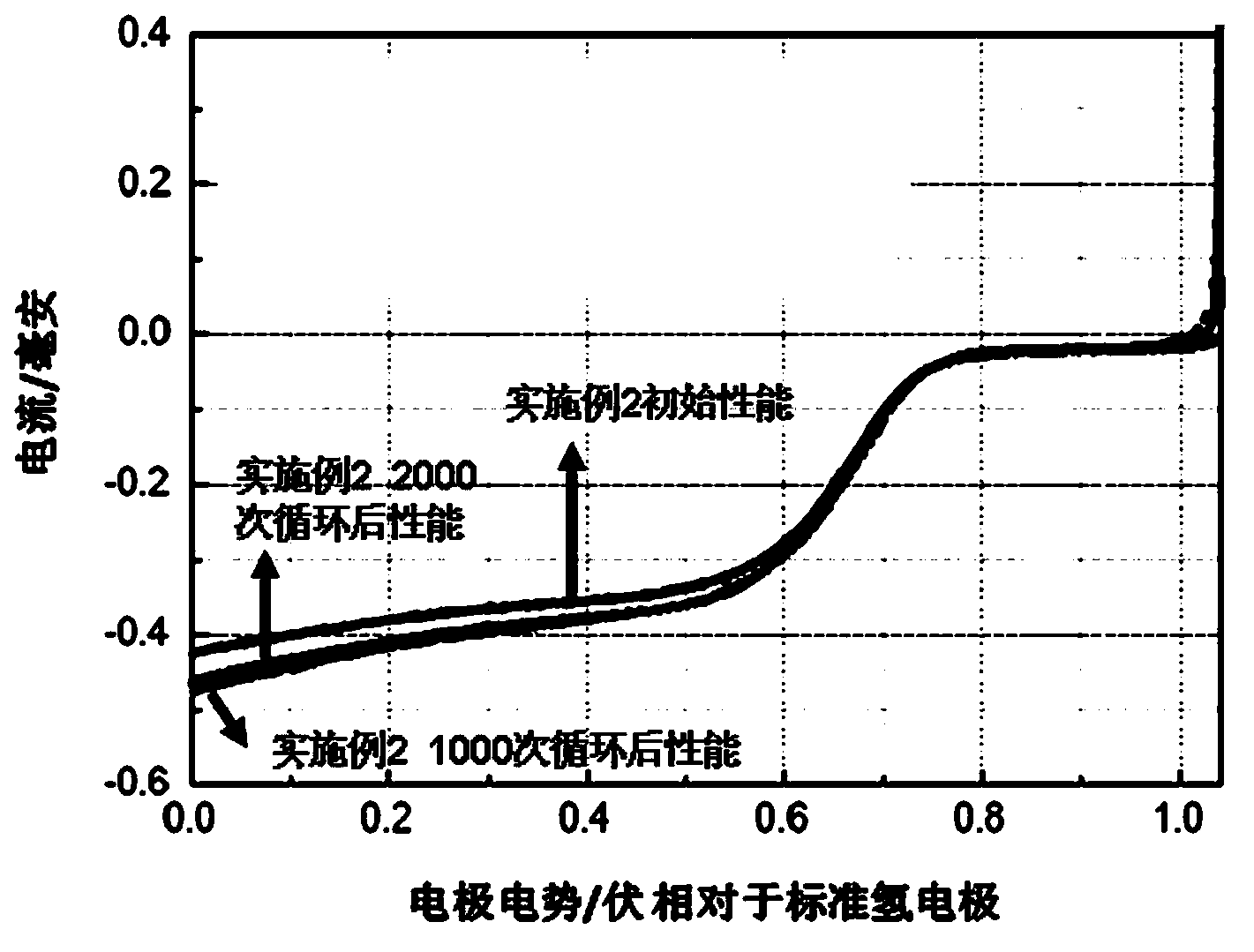

[0052] The now configured aniline hydrochloride solution (5mL aniline+3mL 37.5%HCl+14mL H 2 O) 10 mL. After stirring for 30 minutes, 1mol / L HCl solution was added dropwise to adjust the pH of the solution to 3.0. After 1 h of reaction, 25 mL of 0.5 mol / L (NH 4 ) 2 S 2 o 8 The solution was slowly dropped into the above solution, phenylphosphine was added thereto, the molar ratio of N:P was 10:1, and then 0.35g Fe(NO 3 ) 3 ·6H 2 O, after stirring evenly, polymerize at room temperature for 12 hours, evaporate to dryness, wash, and dry at 85°C, then treat it in an ammonia atmosphere at 900°C for 3 hours to obtain a black powder; put the above powder into 1M acidic aqueous solution , acid treatment for 1 h, washing the metal in the catalyst; then ball milling it with a ball mill for 3 h to obtain a P, N co-doped nano-carbon electrocatalyst with ordered nanostructure.

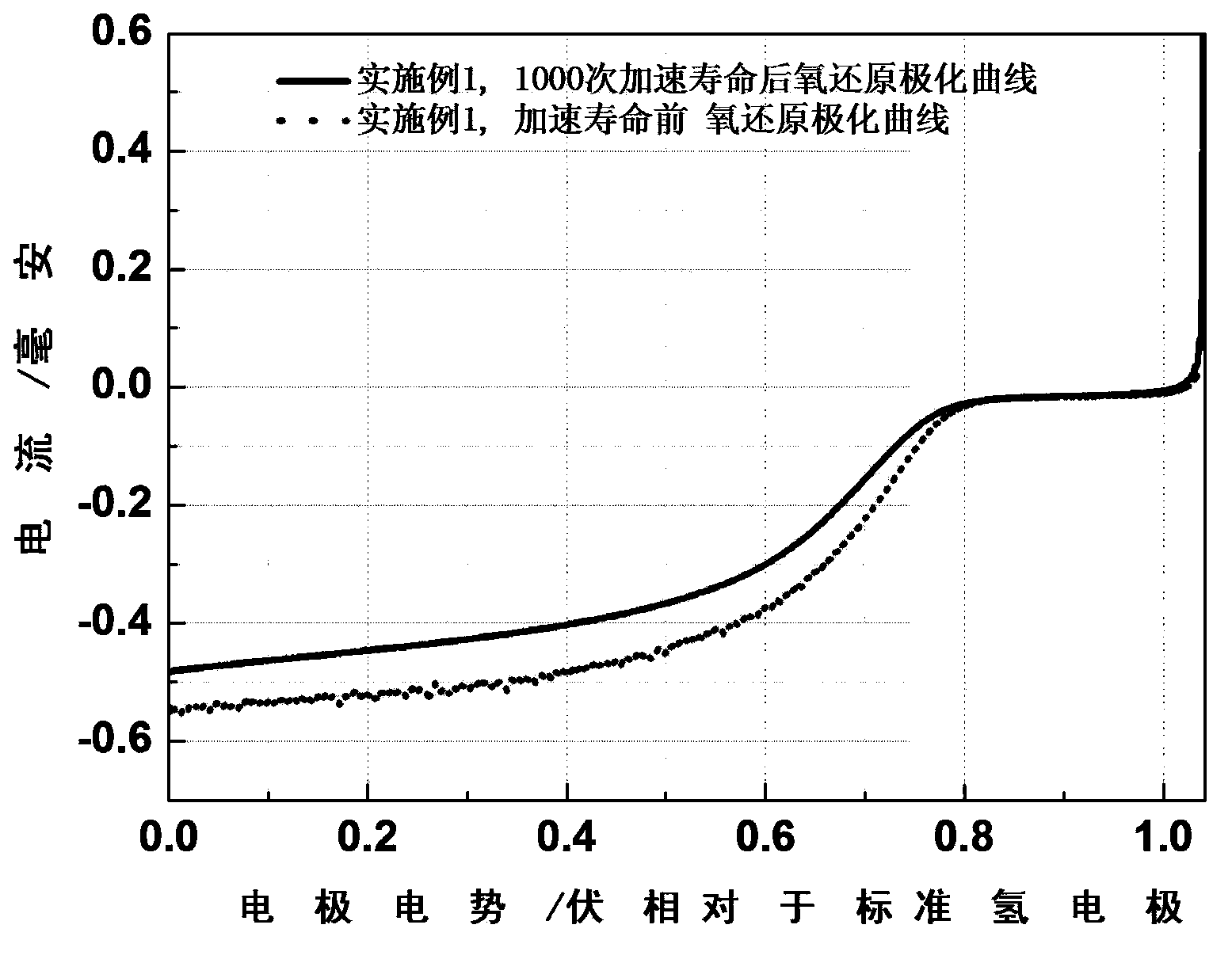

[0053] figure 1 It is a comparison of the oxygen reduction polarization curves before and after the life ...

Embodiment 3

[0056] The now configured polythiophene hydrochloride solution (10mL aniline+6mL 37.5%HCl+28mL H 2 O) 20mL. After stirring for 30 minutes, 1mol / L HCl solution was added dropwise to adjust the pH of the solution to 3.0. After 1 h of reaction, 25 mL of 0.5 mol / L (NH 4 ) 2 S 2 o 8 The solution was slowly dropped into the above solution, phenylphosphine was added thereto, the molar ratio of N:P was 30:1, and then 0.36g Co(NO 3 ) 2 ·6H 2O, after stirring evenly, polymerize at room temperature for 12 hours, evaporate to dryness, wash, and dry at 85°C, then treat it in an ammonia atmosphere at 900°C for 3 hours to obtain a black powder; then use a ball mill for 3 hours to obtain Doped nanocarbon electrocatalysts with ordered nanostructures.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com