Gel polymer electrolyte and preparation method thereof

A gel polymer and electrolyte technology, applied in the manufacture of electrolyte batteries, non-aqueous electrolyte batteries, electrolyte immobilization/gelation, etc., can solve the problem of low conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

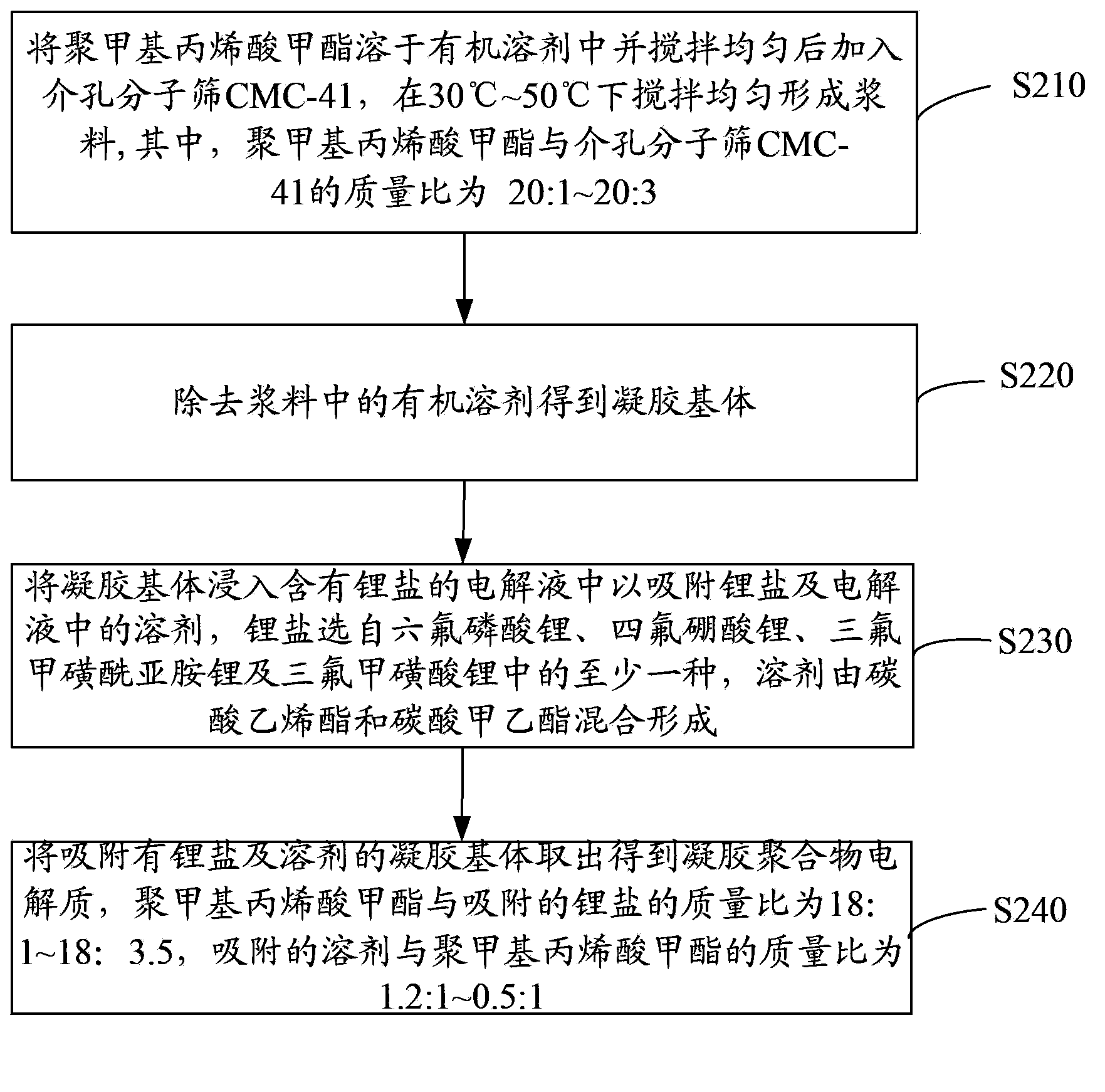

[0039] see figure 1 , the preparation method of above-mentioned gel polymer electrolyte, comprises the following steps:

[0040] Step S210, dissolving polymethyl methacrylate in an organic solvent and stirring evenly, then adding mesoporous molecular sieve MCM-41, stirring evenly at 30°C to 50°C to form a slurry, wherein polymethylmethacrylate and mesoporous The mass ratio of pore molecular sieve MCM-41 is 20:1~20:3.

[0041] Preferably, the organic solvent is at least one selected from N-methylpyrrolidone (NMP), tetrahydrofuran (THF) and acetonitrile (AN).

[0042] Preferably, the solid-to-liquid ratio of the polymethyl methacrylate to the organic solvent is 1g:4ml~2g:3ml.

[0043] Preferably, the molecular weight of the polymethyl methacrylate is 30,000-300,000.

[0044] Preferably, the particle size of the mesoporous molecular sieve MCM-41 is 3 μm to 10 μm.

[0045] In this embodiment, the mesoporous molecular sieve MCM-41 is prepared by the following steps:

[0046] S...

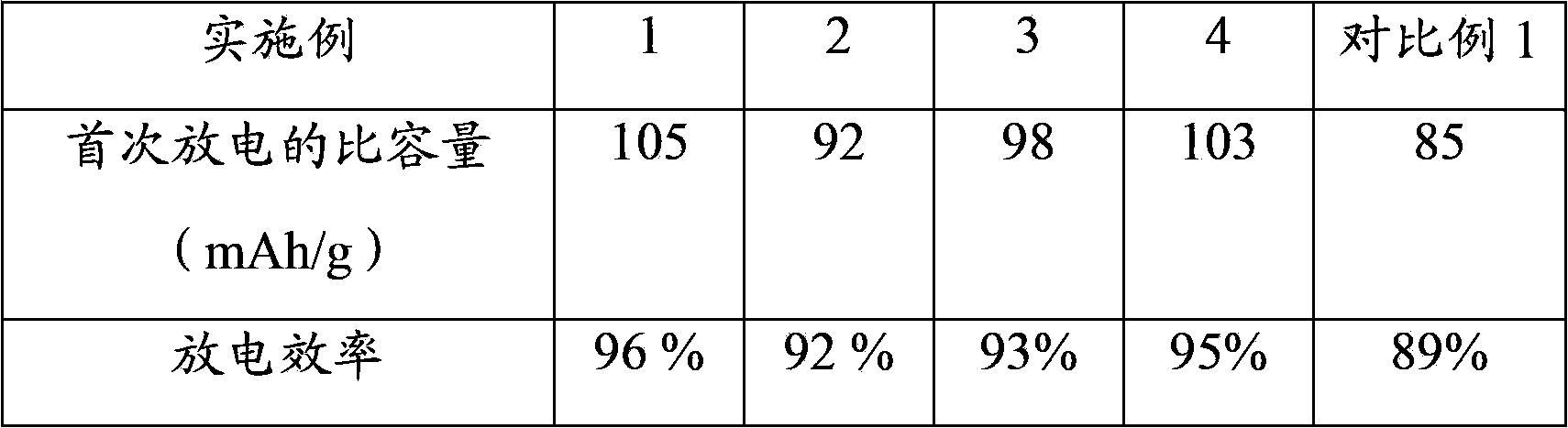

Embodiment 1

[0068] The preparation method of the gel polymer electrolyte in this embodiment includes the following steps:

[0069] (1) Preparation of mesoporous molecular sieves:

[0070] Weigh 1.2g of CTAB (cetyltrimethylammonium bromide), dissolve it in 11mL of distilled water, and stir at 30°C for 30 minutes, then add 3.8g of ethylenediamine (EDA), and continue stirring to disperse the solution evenly . Then slowly add 1.0g tetraethyl orthosilicate (TEOS), continue to stir for 9 hours, stand at room temperature for 20 hours, filter, wash with water until neutral, and dry at 50°C to obtain the original molecular sieve powder (precursor), and then the obtained molecular sieve original powder Calcined in an air atmosphere at 500°C for 6h to remove the organic template (hexadecyltrimethylammonium bromide) to obtain mesoporous molecular sieves.

[0071] (2) Prepared PMMA-based gel polymer electrolyte modified by mesoporous molecular sieve:

[0072] Dissolve 10g PMMA (molecular weight: 10...

Embodiment 2

[0075] The preparation method of the gel polymer electrolyte in this embodiment includes the following steps:

[0076] (1) Preparation of mesoporous molecular sieves:

[0077] Weigh 1.0g of CTAB (cetyltrimethylammonium bromide), dissolve it in 10mL of distilled water, and stir at 20°C for 100 minutes, then add 3.5g of ethylenediamine (EDA), and continue stirring to disperse the solution evenly . Then slowly add 1.0g tetraethyl orthosilicate (TEOS), continue to stir for 6h, let stand at room temperature for 15h, filter, wash with water until neutral, and dry at 40°C to obtain the original powder of molecular sieve, and then put the obtained original powder of molecular sieve at 400°C Calcined in the air atmosphere for 3h to remove the organic template, that is, to obtain the mesoporous molecular sieve.

[0078] (2) Prepared PMMA-based gel polymer electrolyte modified by mesoporous molecular sieve:

[0079] Dissolve 10g of PMMA (molecular weight: 30,000) in about 15mL of acet...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com