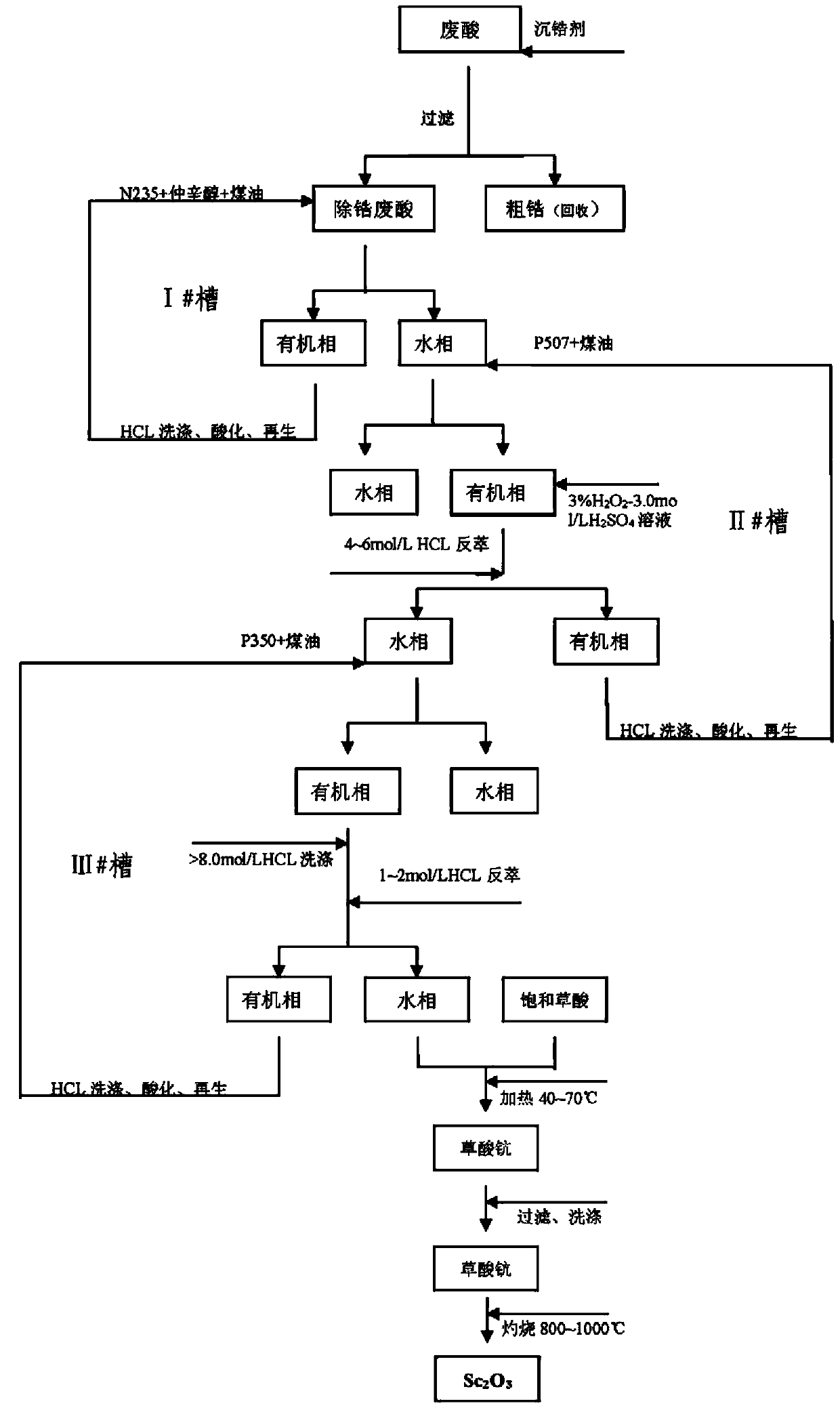

Method for recycling and purifying scandium oxide powder from waste acid in zirconium salt production

A technology for producing zirconium salt and scandium oxide, which is applied in the fields of hydrometallurgy and the treatment and comprehensive utilization of zircon sand waste acid, can solve the problems of difficulty in similarity separation, affecting the extraction capacity and extraction rate of organic relative scandium, and achieves a reduction in processing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] The recovery and purification of scandium oxide from the waste acid solution of producing zirconium salt is carried out according to the following steps:

[0050] The steps of raw material preparation and zirconium precipitation agent precipitation zirconium: first discharge 2000L waste acid solution from the discharge port into an 800-mesh filter bag for filtration, the filtrate flows into the flow tank, and inject the filtered waste acid solution into the sedimentation tank with an acid-resistant pump. After the waste acid in the precipitation tank reaches a certain volume, zirconium precipitation begins; while stirring, a certain amount of ammonium phosphate, a zirconium precipitation agent, is slowly and evenly added to the precipitation tank, and the stirring frequency is gradually increased as the amount of white precipitate increases until the material Stop stirring when the liquid is white and viscous and the color is stable. And use 400-mesh filter bag to filte...

Embodiment 2

[0061] Different from Example 1, the steps of raw material preparation and zirconium precipitation agent precipitation zirconium.

[0062] Filter 1000L of waste acid with an 800-mesh filter bag, the filtrate flows into the launder, and inject the filtered waste acid into the sedimentation tank with an acid-resistant pump, and start to precipitate zirconium after the waste acid in the sedimentation tank reaches a certain volume; A certain amount of zirconium-precipitating phosphoric acid (directly use industrial-grade phosphoric acid, the dosage is 60L, about 10% in excess) is slowly and evenly added to the sedimentation tank, and the stirring frequency is gradually increased with the increase of the amount of white sediment until the feed liquid is white and viscous. Stop stirring when it is thick and the color is stable. And use 400-mesh filter bag to filter, the filter cake is collected separately for further processing or used directly as crude zirconium, and the filtrate i...

Embodiment 3

[0066] Different from Examples 1 and 2, the step of extracting and removing iron with N235 is adopted.

[0067] Filter 1000L of waste acid with an 800-mesh filter bag, the filtrate flows into the launder, and inject the filtered waste acid into the sedimentation tank with an acid-resistant pump, and start to precipitate zirconium after the waste acid in the sedimentation tank reaches a certain volume; A certain amount of zirconium-precipitating phosphoric acid (directly use industrial-grade phosphoric acid, the dosage is 60L, about 10% in excess) is slowly and evenly added to the sedimentation tank, and the stirring frequency is gradually increased with the increase of the amount of white sediment until the feed liquid is white and viscous. Stop stirring when it is thick and the color is stable. A 400-mesh filter bag is used to filter, the filter cake is collected separately for further processing, and the filtrate is collected into the launder.

[0068] Take about 10mL of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com