Sensitive, reliable, rapid and stable synchronous detection method for iron ore multi-elements

A simultaneous detection and iron ore technology, applied in the preparation of test samples, thermal excitation analysis, material excitation analysis, etc., can solve the problem of accuracy of detection results, unsatisfactory reproducibility, narrow detection range of atomic absorption spectrometry, The analysis results have a relatively large impact, and achieve the effects of reducing volatile emissions and impurity pollution, high sex-to-background ratio, and rich spectral lines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] ——Detection of arsenic iron ore YSBC14721-98

[0044] A. Sample preparation: put 0.15g of the powder of arsenic-containing iron ore YSBC14721-98 to be tested into a polytetrafluoroethylene beaker, add a mixed acid of hydrochloric acid and nitric acid with a volume ratio of 4:1 according to the dosage of 225ml / g, and dissolve the sample Dissolve to obtain solution a; add hydrofluoric acid to solution a according to the dosage of 9ml / ml, heat at 225°C for 12min to obtain solution b; add perchloric acid to solution b according to the dosage of 5ml / ml , heated at 225°C until smoking, 1ml of the solution remained, and the solution c was obtained after cooling; according to the dosage of 12ml / ml, dilute hydrochloric acid mixed with hydrochloric acid and water at a volume ratio of 1:1 was added to the solution c to dissolve After filtering, dilute the filtrate with water to 0.001g / ml to obtain the test solution d.

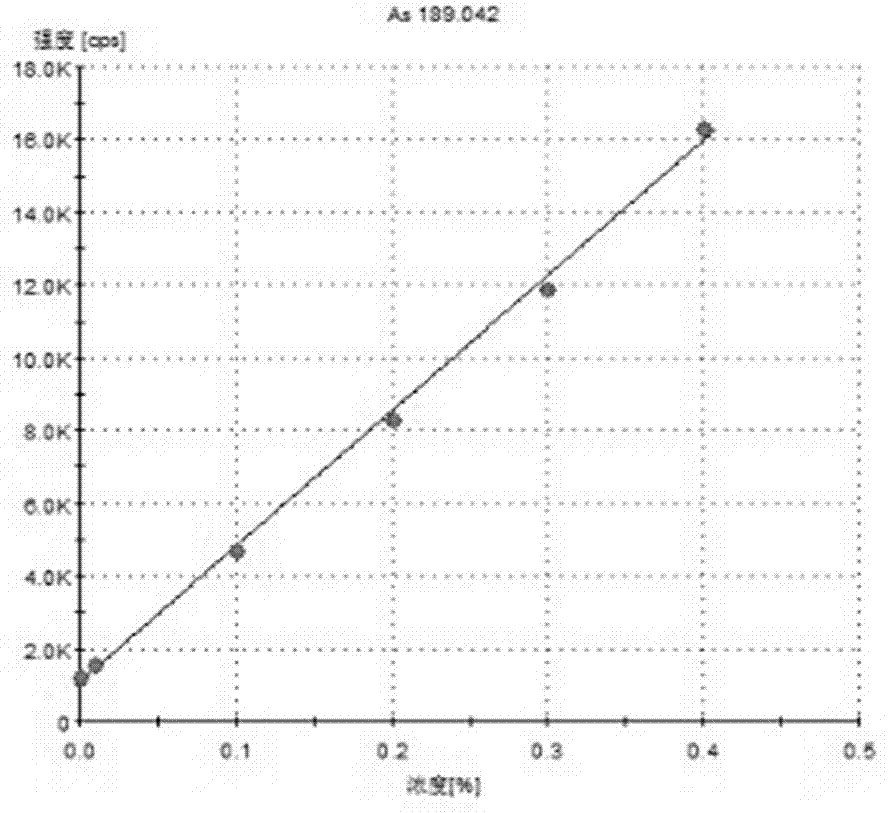

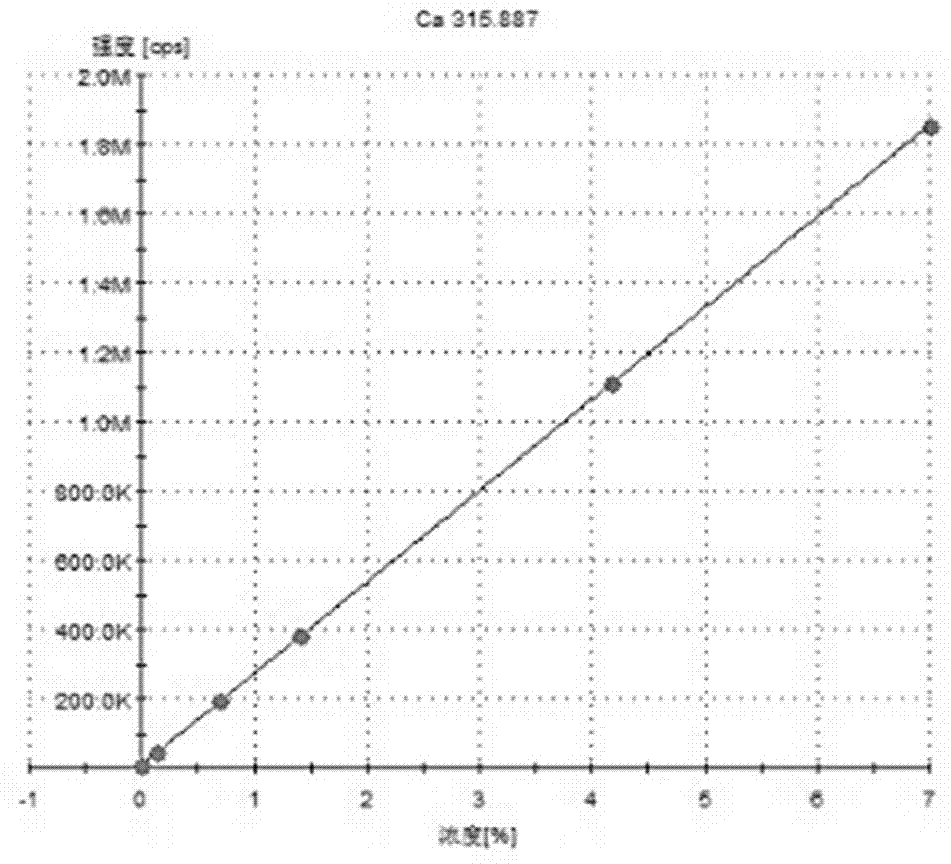

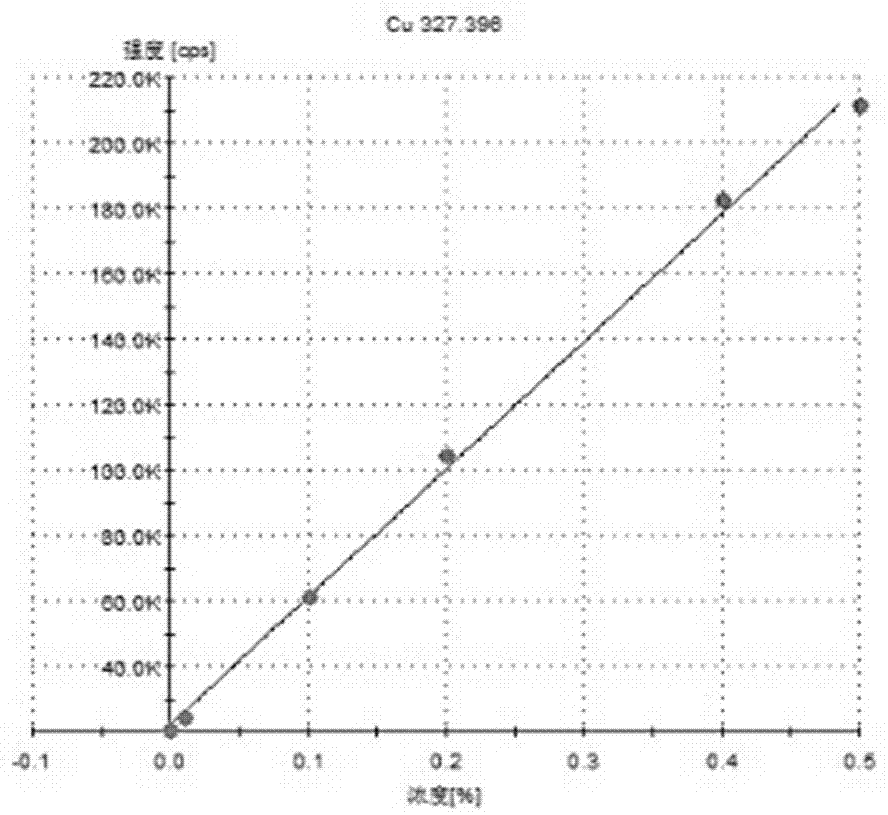

[0045] B. Calibration: Set the working conditions of the ind...

Embodiment 2

[0056] ——Detection of vanadium-titanium magnetite concentrate YSBC19717-2005

[0057] A, sample preparation: 0.1g of the powder of the vanadium-titanium magnetite concentrate YSBC19717-2005 to be tested is placed in a polytetrafluoroethylene beaker, and a mixed acid of hydrochloric acid and nitric acid with a volume ratio of 5:1 is added according to the consumption of 200ml / g. Dissolve the sample to obtain solution a; add hydrofluoric acid to solution a according to the dosage of 7ml / ml, heat at 250°C for 10 minutes to obtain solution b; add perchloric acid to solution b according to the dosage of 4ml / ml Acid, heated at 250°C until smoking, 0.8ml of solution remains, and after cooling, solution c is obtained; according to the dosage of 10ml / ml, add dilute hydrochloric acid mixed with hydrochloric acid and water at a volume ratio of 1:1.2 to solution c , filtered after dissolving, and dilute the filtrate to 0.0008g / ml with water to obtain the test solution d.

[0058] B. Cali...

Embodiment 3

[0069] ——Detection of iron ore YSBC13710-95

[0070] A. Sample preparation: put 0.2g of the powder of iron ore YSBC13710-95 to be tested into a polytetrafluoroethylene beaker, add a mixed acid of hydrochloric acid and nitric acid with a volume ratio of 3:1 according to the dosage of 250ml / g, and dissolve the sample , to obtain the solution a; add hydrofluoric acid to the solution a according to the dosage of 12ml / ml, and heat at 200°C for 15min to obtain the solution b; add perchloric acid to the solution b according to the dosage of 6ml / ml, Heating at 200°C until smoking, 1.2ml of the solution remains, and after cooling, the solution c is obtained; add dilute hydrochloric acid mixed with hydrochloric acid and water at a volume ratio of 1:0.8 to the solution c according to the dosage of 15ml / ml, and dissolve After filtering, dilute the filtrate with water to 0.0012g / ml to obtain the test solution d.

[0071] B. Calibration: Set the working conditions of the inductively couple...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com