Manufacturing method for lithium ion battery diaphragm

A technology for lithium-ion batteries and diaphragms, which is applied to battery components, chemical instruments and methods, circuits, etc., and can solve problems such as poor control of porosity and pore size, uneven pore size distribution, and poor thermal stability. , to achieve the effect of good pro/liquid retention performance, uniform mechanical strength, and regular arrangement of fiber chains

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

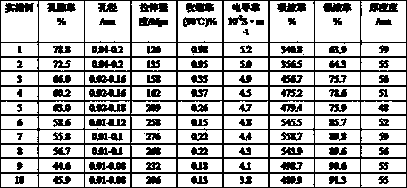

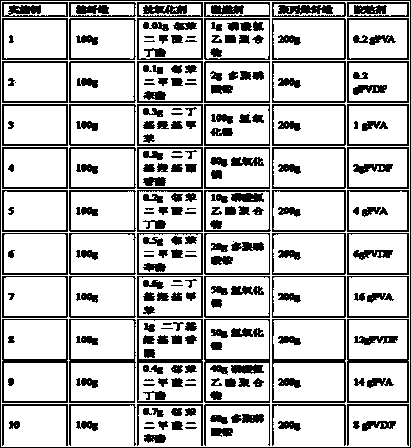

[0027] See Table 1 for the original formulation of the Li-ion battery separator in this example.

[0028] The preparation method of the lithium-ion battery separator of the present embodiment comprises the following steps:

[0029] (1) Weigh each raw material according to the ratio of raw materials shown in Table 1, make a mixture of cotton fiber and water at a ratio of 4:100, put it in a beater, and obtain cotton pulp with a beating degree of 60°, and dehydrate it. , measure its moisture content;

[0030] (2) Make a mixture of the cotton pulp obtained in step (1) and water at a ratio of 1:100, add antioxidants and flame retardants, stir and disperse, dehydrate and form on a copper grid, and then press and dry at 90°C to form a film ,stand-by;

[0031] (3) Make a suspension of modified polypropylene fiber and water at a ratio of 1:100, add an adhesive, stir, and evenly disperse it on a copper grid for dehydration to form, and dry at 110°C to form a film;

[0032] (4) Repeat...

Embodiment 2

[0036] See Table 1 for the original formulation of the Li-ion battery separator in this example.

[0037] The preparation method of the lithium-ion battery separator of the present embodiment comprises the following steps:

[0038] (1) Weigh each raw material according to the ratio of raw materials shown in Table 1, make a mixture of cotton fiber and water at a ratio of 4:100, put it in a beater, and obtain cotton pulp with a beating degree of 60°, and dehydrate it. , measure its moisture content;

[0039] (2) Make a mixture of cotton pulp and water obtained in step (1) at a ratio of 1:100, add antioxidants and flame retardants, stir and disperse, dehydrate and form on a copper grid, and then press and dry at 110°C to form a film ,stand-by;

[0040] (3) Make a suspension of modified polypropylene fiber and water at a ratio of 1:100, add an adhesive, stir, and evenly disperse it on a copper grid for dehydration to form, and dry at 90°C to form a film;

[0041] (4) Repeat ste...

Embodiment 3

[0045] See Table 1 for the original formulation of the Li-ion battery separator in this example.

[0046] The preparation method of the lithium-ion battery separator of the present embodiment comprises the following steps:

[0047] (1) Weigh each raw material according to the ratio of raw materials shown in Table 1, make a mixture of cotton fiber and water at a ratio of 4:100, put it in a beater, and obtain cotton pulp with a beating degree of 60°, and dehydrate it. , measure its moisture content;

[0048] (2) Make a mixture of cotton pulp and water obtained in step (1) at a ratio of 1:100, add antioxidants and flame retardants, stir and disperse, dehydrate and form on a copper grid, and then press and dry at 110°C to form a film ,stand-by;

[0049] (3) Make a suspension of modified polypropylene fiber and water at a ratio of 1:100, add an adhesive, stir, and evenly disperse it on a copper grid for dehydration to form, and dry at 90°C to form a film;

[0050] (4) Repeat ste...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com