Double-resonant-cavity all-optical-fiber mode-locked pulse laser

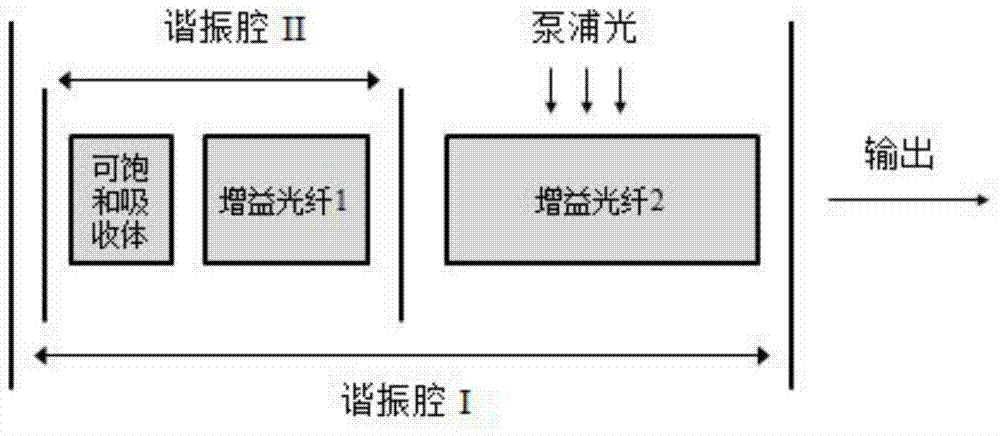

A mode-locked pulse, dual-resonator technology, which is applied in the fields of laser technology, fiber optics and nonlinear optics, can solve the problems of poor anti-interference ability, high production cost and high cost, and achieves high pulse energy, simple design and compact structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

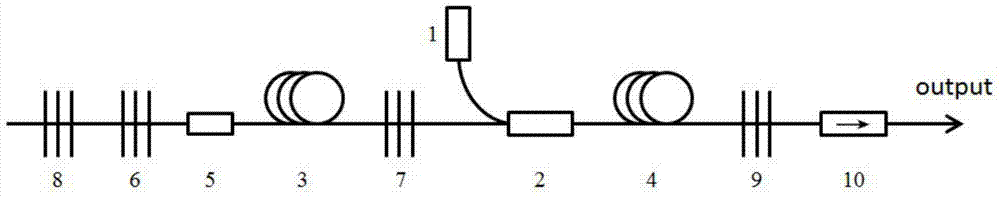

[0055] Such as Figure 5 As shown, the pump source 1 in the figure is a semiconductor laser diode with a center wavelength of 976nm; the fiber combiner 2 is a (2+1)×1 pump signal combiner, such as 6 / 125 or 20 / 125 type; 3 and 4 are rare-earth-doped optical fibers, and high-performance ytterbium-doped optical fibers produced by Nufern Company in the United States can be used; 5 is a saturable absorber, and graphene, carbon nanotubes or topological insulators can be used; the first reflective optical fiber Bragg The grating 6, the second reflective fiber Bragg grating 7, the third reflective fiber Bragg grating 8, and the fourth reflective fiber Bragg grating 9 can be either full-reflective or partially reflective gratings, and the reflectivity is R, where 0<R< 1; The optical isolator 10 can be a polarization-independent optical isolator.

[0056] The pump light enters the second gain fiber 4 through the pump end of the fiber combiner 2, and then reaches the fourth reflective f...

Embodiment 2

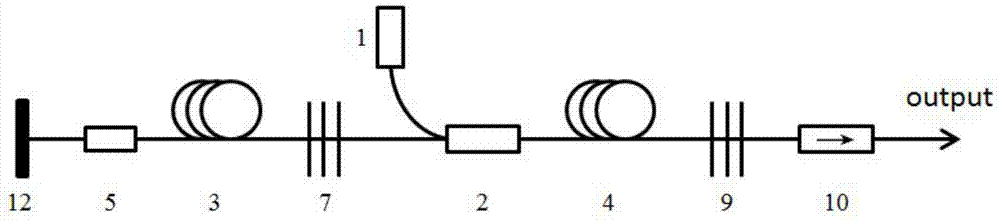

[0058] Such as Image 6 As shown, the pump source 1 in the figure is a semiconductor laser diode with a center wavelength of 976nm; the fiber combiner 2 is a (2+1)×1 pump signal combiner, such as 6 / 125 or 20 / 125 type; 3 and 4 are rare-earth-doped optical fibers, and high-performance ytterbium-doped optical fibers produced by Nufern Company in the United States can be used; 5 is a saturable absorber, and graphene, carbon nanotubes or topological insulators can be used; the first reflective optical fiber Bragg The grating 6, the second reflective fiber Bragg grating 7, and the third reflective fiber Bragg grating 8 can choose total reflection or partial reflection grating, and the reflectivity is R, where 0<R<1; the optical isolator 10 can choose polarization An irrelevant optical isolator; the fourth reflective fiber Bragg grating 9 is replaced by a total reflection mirror 12 .

[0059] The pump light enters the second gain fiber 4 through the pump end of the fiber combiner 2...

Embodiment 3

[0061] Such as Figure 7 As shown, the pump source 1 is a semiconductor laser diode with a center wavelength of 976nm; the wavelength division multiplexer 15 is a 980 / 1060nm single-mode wavelength division multiplexer; the first gain fiber 3 and the second gain fiber 4 are rare earth-doped fibers , the high-performance ytterbium-doped optical fiber produced by Nufern Company in the United States can be selected; the saturable absorber 5 can be selected from graphene, carbon nanotubes or topological insulators; the first reflective fiber Bragg grating 6 and the second reflective fiber Bragg grating 7 are optional Total inversion or partial reflection grating, its reflectivity is R (0<R<1); 10 is an optical isolator, optional polarization-independent optical isolator; beam splitter 13 can be a 90:10 fiber optic beam splitter; The optical fiber filter 14 may be a 1um band narrow-band filter.

[0062]The pump light passes through the 980nm end of the wavelength division multiplex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com