Method for producing biological feed additive by using cassava residue and waste alcohol sediment liquid

A technology for alcohol waste mash and biological feed is applied in the field of production of biological feed additives, which can solve the problem of high cost and achieve the effects of inhibiting ammonia gas, promoting growth and improving air environment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

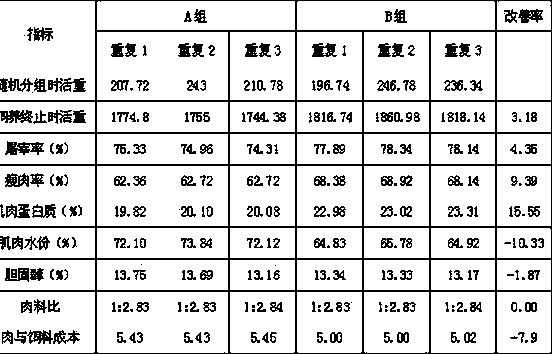

[0018] The alcohol waste mash and cassava residue are mixed according to the weight ratio of 5:3, sterilized and introduced into the bacteria, the bacteria introduced are Bacillus subtilis, Bacillus licheniformis and Aspergillus niger 1:2:2 The ratio of the number of bacteria is configured, the bacteria is 5% of the weight of the wet cassava residue mixture, and then fermented, the fermentation time is controlled at 5 days, the temperature is controlled at 50 ° C during the fermentation process, and the pH is accepted during the fermentation process. =2 domestication. The fermented cassava residue mixture is dried to finally obtain a biological feed additive containing a large amount of microbial cells, and the feed additive is mixed with part of the complete feed to obtain high-quality livestock and poultry feed, which can be used to feed pigs.

[0019] Example 2

[0020] The alcohol waste mash and cassava residue are mixed according to the weight ratio of 8:4, sterilized an...

Embodiment 3

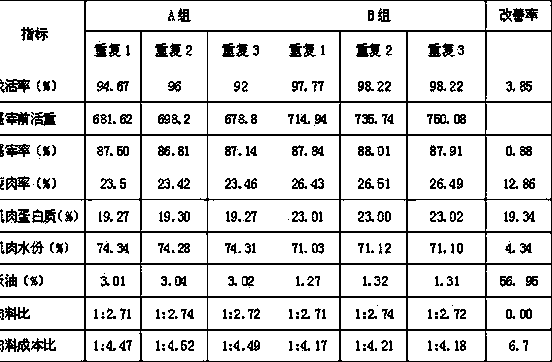

[0023] The alcohol waste mash and cassava residue are mixed according to the weight ratio of 10:3, sterilized and introduced into the strains, the strains inserted are Bacillus subtilis, Bacillus licheniformis and Aspergillus niger 2:1:1 The ratio of the number of bacteria is configured. The bacteria are 10% of the weight of the wet cassava residue mixture, and then fermented. The fermentation time is controlled at 10 days. The temperature is controlled at 60°C during the fermentation process. =5 domestication. In fact, the fermented cassava residue mixture is dried to finally obtain a biological feed additive containing a large amount of microbial cells. The feed additive is mixed with part of the complete feed to obtain high-quality livestock and poultry feed, which can be used to feed chickens.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com