Low-contraction high-cementation inorganic thermal-insulation mortar

An inorganic thermal insulation mortar and high-bonding technology, which is applied in the field of building energy-saving thermal insulation materials, can solve the problems of low bonding strength and large drying shrinkage of inorganic thermal insulation mortar, and achieve low thermal conductivity, environmental protection, and improved activity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

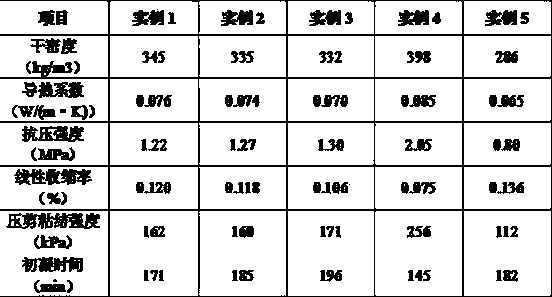

Examples

Embodiment 1

[0041] Example 1: A low-shrinkage and high-bonding inorganic thermal insulation mortar, the weight percentage of each component is: 13.1% of dead-burned magnesium oxide, 8.9% of potassium dihydrogen phosphate, 27.0% of phosphorus slag, and 6.0% of fly ash %, vitrified microbeads 40.0%, borax 0.53%, barium hydroxide 0.47%, natron 3.0%, ethylene / vinyl acetate copolymer 0.59%, hydroxypropyl methyl cellulose ether 0.29 %, lignin fiber is 0.12%.

Embodiment 2

[0042] Example 2: A low-shrinkage and high-bonding inorganic thermal insulation mortar, the weight percentage of each component is: 15.0% of dead-burned magnesium oxide, 12.8% of potassium dihydrogen phosphate, 21.6% of phosphorus slag, and 6% of fly ash %, vitrified microbeads 40.0%, borax 0.75%, barium hydroxide 0.45%, natron 2.4%, ethylene / vinyl acetate copolymer 0.59%, hydroxypropyl methyl cellulose ether 0.29 %, lignin fiber is 0.12%.

Embodiment 3

[0043] Example 3: A low-shrinkage and high-bonding inorganic thermal insulation mortar, the weight percentage of each component is: 16.0% of dead-burned magnesium oxide, 18.2% of potassium dihydrogen phosphate, 16.2% of phosphorus slag, and 6.0% of fly ash %, vitrified microbeads 40.0%, borax 0.48%, barium hydroxide 0.32%, natron 1.8%, ethylene / vinyl acetate copolymer 0.59%, hydroxypropyl methyl cellulose ether 0.29 %, lignin fiber is 0.12%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com