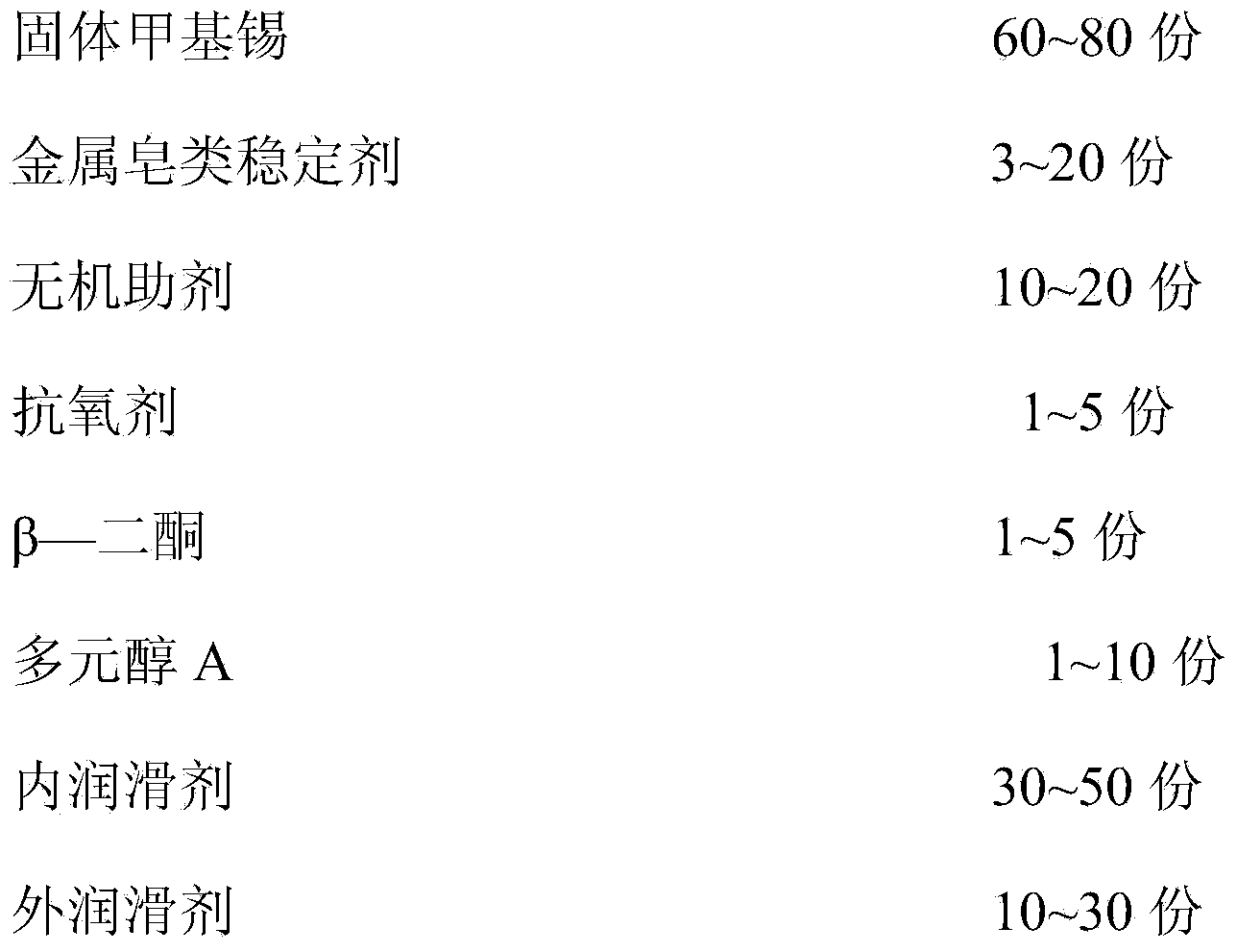

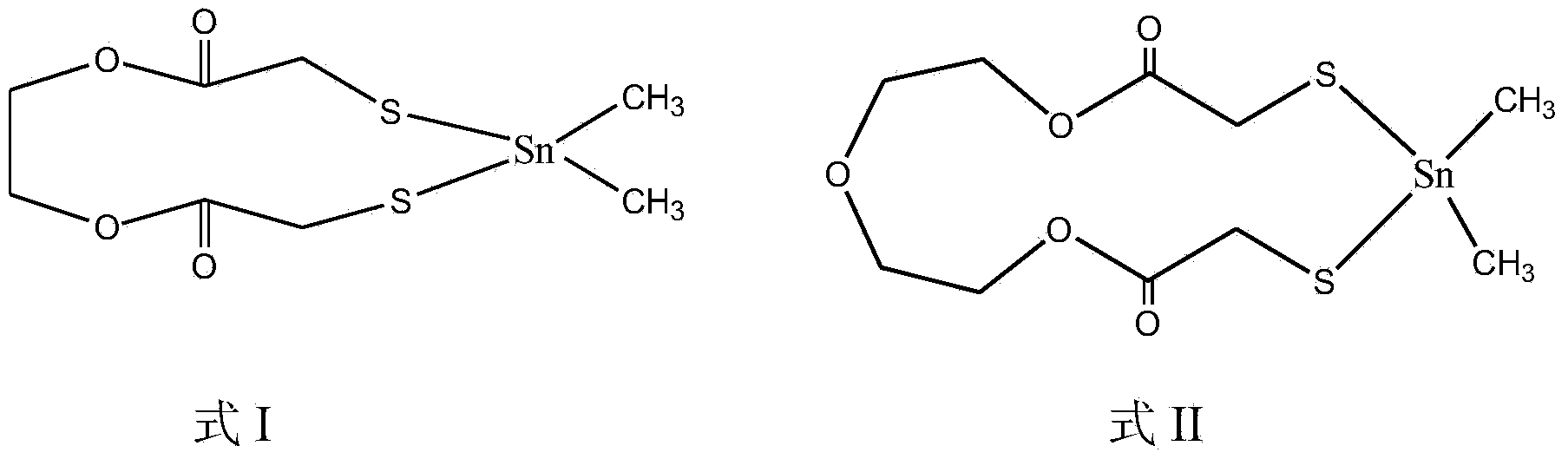

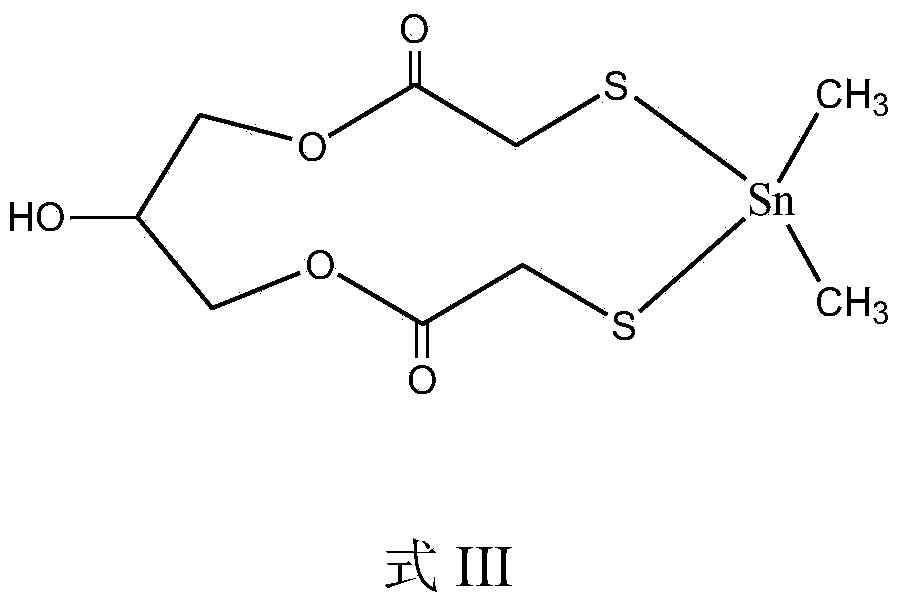

Solid methyltin mercaptide complex heat stabilizer and preparation method and application thereof

A composite heat stabilizer and heat stabilizer technology, applied in the direction of tin organic compounds, etc., can solve the problems of low tin content and insufficient self-lubricating property of methyl tin compounds, achieve the best stability and lubrication effect, and improve the stability efficiency. , the effect of reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] According to the distribution ratio of raw materials, put 60kg of solid methyl tin and 3kg of zinc stearate into the reaction kettle first, stir and mix, control the stirring speed at 80r / min, and control the temperature at 65°C for 1h, then add 12kg of modified hydrotalcite, 2, 2kg of 6-di-tert-butyl-p-cresol, 2kg of dibenzoylmethane, 2kg of pentaerythritol, 12kg of polyethylene wax, and 32kg of pentaerythritol stearate are added in proportion, kept at 65°C and mixed for 20 minutes, cooled to room temperature, and sliced. Described solid methyl tin composite thermal stabilizer 125kg.

Embodiment 2

[0046] According to the ratio of raw material components, put 66kg of solid methyl tin and 7kg of calcium stearate into the reaction kettle first, stir and mix, control the stirring speed at 95r / min, control the temperature at 70°C and mix for 1.5h, then add 13kg of modified zeolite, four [ β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate] pentaerythritol ester 2kg, stearyl benzoylmethane 2kg, sorbitol 3kg, oxidized polyethylene wax 14kg, hard stearate 32 kg of fatty alcohol esters were added in proportion, kept at 70° C. and mixed for 30 minutes, cooled, and sliced into 139 kg of the solid methyl tin composite thermal stabilizer.

[0047] Tin content (%) 12.25%.

Embodiment 3

[0049]According to the distribution ratio of raw materials, 69kg of solid methyl tin and 9kg of magnesium stearate were first put into the reaction kettle, stirred and mixed, the stirring speed was controlled at 115r / min, and the temperature was controlled at 75°C for 2h, and then 14kg of modified hydrotalcite, three [ 2. 3kg of 4-di-tert-butylphenyl] phosphite, 4kg of dibenzoylmethane, 4kg of maltitol, 16kg of polyethylene wax, and 35kg of stearyl adipate were added in proportion, kept at 75°C for 35 minutes, cooled, After slicing, it is 154kg of the solid methyl tin composite thermal stabilizer.

[0050] Tin content (%): 12.15%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com