Environment protection-type interior wall paint with formaldehyde purification function and preparation method therefor

An environmentally friendly technology for interior wall coatings, applied in the field of coatings, can solve the problems of unsatisfactory purification effect of pure aldehyde coatings, shortage of resources, and rising prices.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

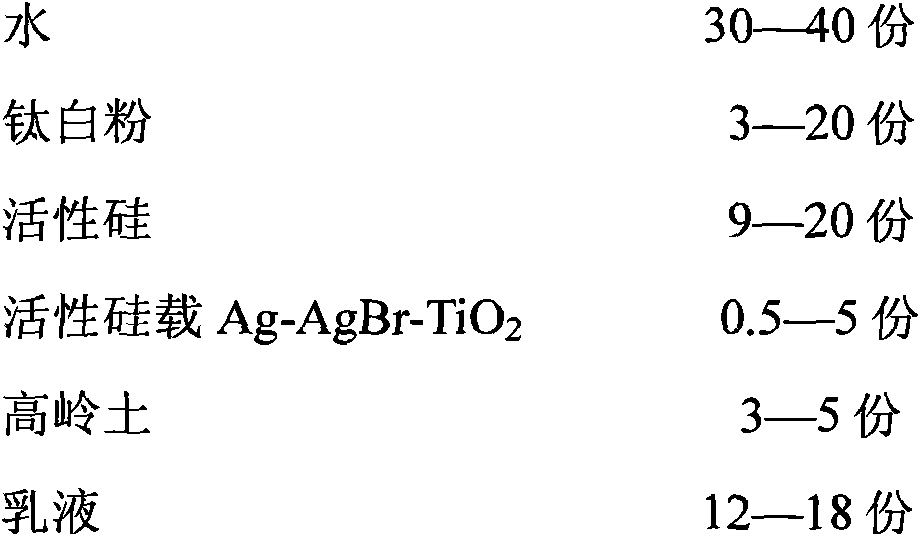

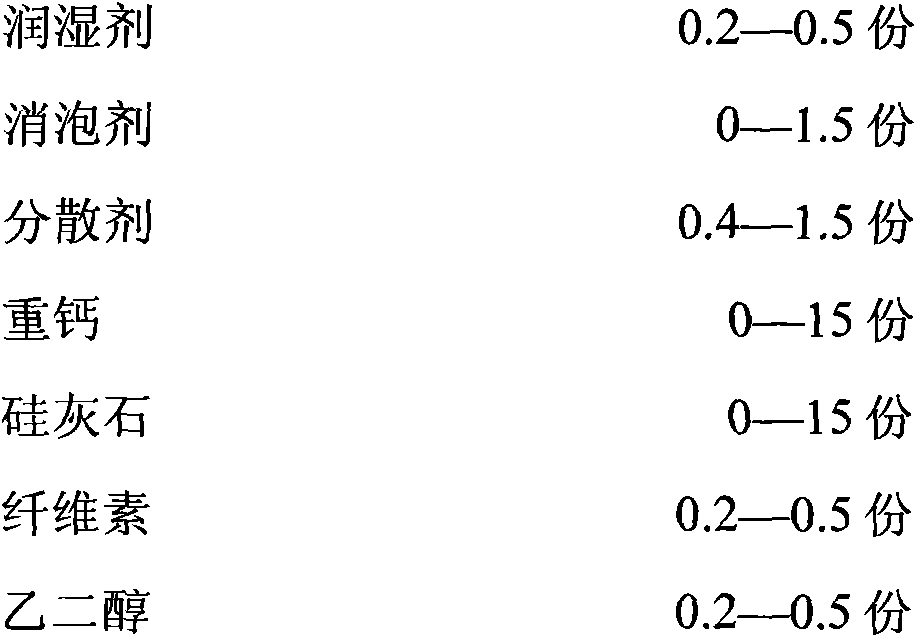

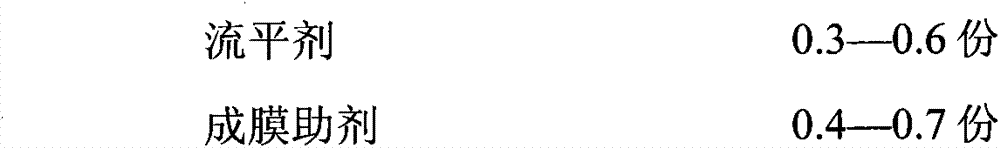

Method used

Image

Examples

Embodiment 1

[0052] Put 35 parts of water into the stainless steel barrel, add 0.2 parts of wetting agent, 0.3 parts of defoamer, 0.5 parts of dispersant, 8 parts of titanium dioxide, 12 parts of Active silicon, 0.96 parts active silicon loaded Ag-AgBr-TiO 2 , 11 parts of heavy calcium, 10 parts of wollastonite, and 4 parts of kaolin, uniformly disperse at this speed for 30 minutes. Adjust the rotation speed to 800r / min, stir the above dispersion system at this rotation speed, and slowly add 16 parts of emulsion at the same time, keep the rotation speed to uniformly disperse for 15min. Adjust the rotation speed to 500r / min, stir the above emulsion at this rotation speed, and slowly add 0.4 parts of cellulose, 0.5 parts of ethylene glycol, 0.6 parts of leveling agent, and 0.5 parts of film-forming aid to maintain the rotation speed After uniform dispersion for 20 minutes, add an appropriate amount of pH regulator to adjust the pH within the range of 8-10. Then stir the above emulsion at a...

Embodiment 2

[0056] Change active silicon and active silicon loaded Ag-AgBr-TiO 2 The amount of addition, add 9 parts of active silicon, 0.72 parts of active silicon loaded Ag-AgBr-TiO 2 , the method for preparing coating is the same as embodiment 1, wherein, water is 33 parts, and wetting agent is 0.3 part, and defoamer is 1.2 parts, and dispersant is 0.8 part, and titanium dioxide is 6 parts, and heavy calcium is 15 parts, Wollastonite is 14 parts, kaolin is 3 parts, emulsion is 16 parts, cellulose is 0.4 parts, ethylene glycol is 0.5 parts, leveling agent is 0.4 parts, and film-forming aid is 0.5 parts.

[0057] The above coatings were sent to the Inner Mongolia Autonomous Region Product Quality Inspection Research Institute for testing according to GB / T9756-2009 "Synthetic Resin Emulsion Interior Wall Coatings". The limit of harmful substances in interior wall coatings of decoration materials was tested, and the test results showed that the coating met the requirements of the limit of...

Embodiment 3

[0060] Change active silicon and active silicon loaded Ag-AgBr-TiO 2 The amount of addition, add 13 parts of active silicon, 1.04 parts of active silicon loaded Ag-AgBr-TiO 2 , the method for preparing the coating is the same as in Example 1, wherein 36 parts of water, 0.3 parts of wetting agent, 1.2 parts of defoamer, 0.8 part of dispersant, 5 parts of titanium dioxide, and 12 parts of heavy calcium, Wollastonite is 12 parts, kaolin is 3 parts, emulsion is 17 parts, cellulose is 0.4 parts, ethylene glycol is 0.3 parts, leveling agent is 0.5 parts, and film-forming aid is 0.4 parts.

[0061] The above coatings were sent to the Inner Mongolia Autonomous Region Product Quality Inspection Research Institute for testing according to GB / T9756-2009 "Synthetic Resin Emulsion Interior Wall Coatings". The limit of harmful substances in interior wall coatings of decoration materials was tested, and the test results showed that the coating met the requirements of the limit of harmful su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com