Palladium-doped stannic oxide wrapped carbon nano tube as well as preparation method and application of nano tube

A technology of tin dioxide and carbon nanotubes, applied in measuring devices, material analysis through electromagnetic means, instruments, etc., can solve the problems of low gas sensitivity performance and long response-recovery time, achieve high sensitivity and improve gas sensitivity Performance, easy-to-achieve effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

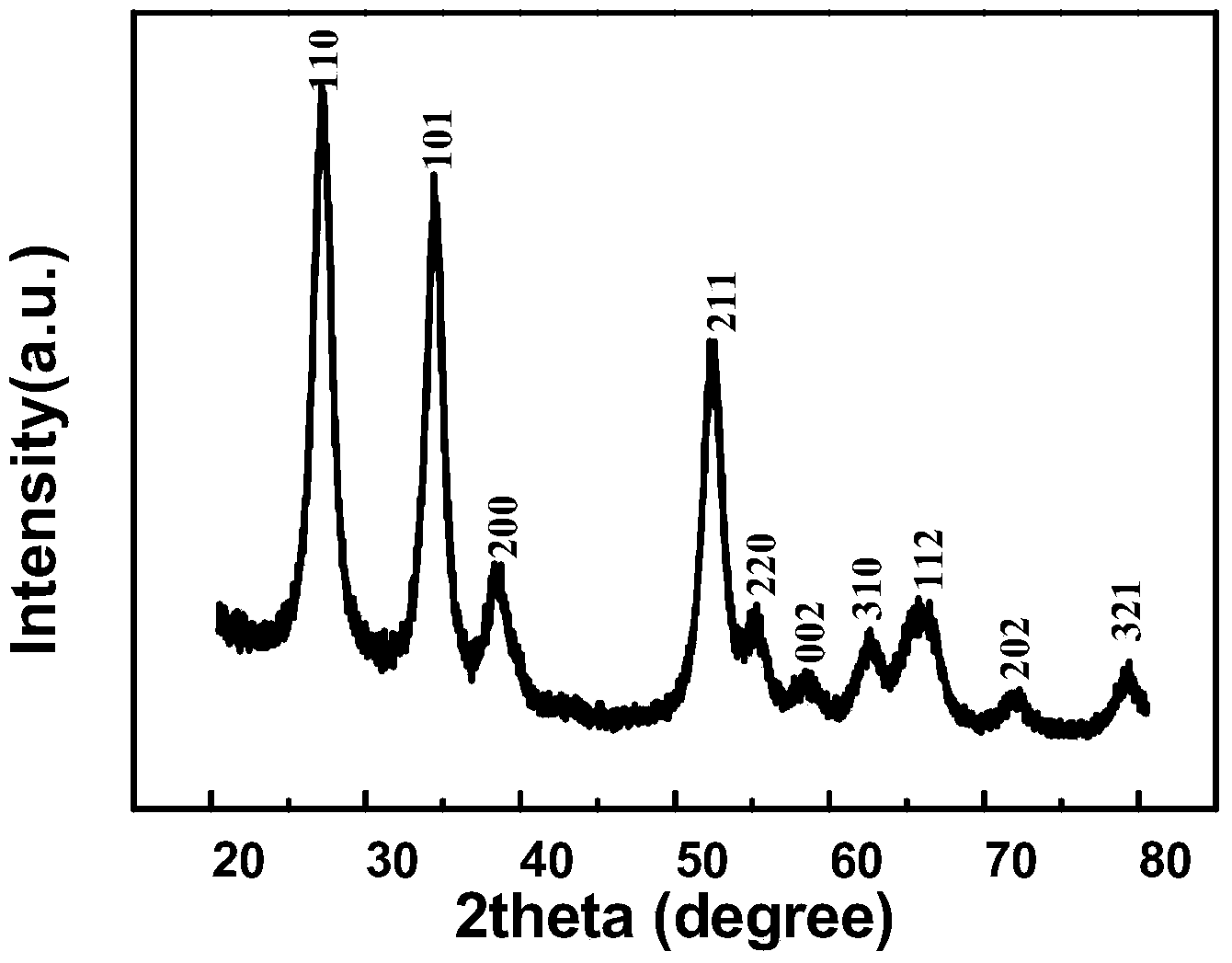

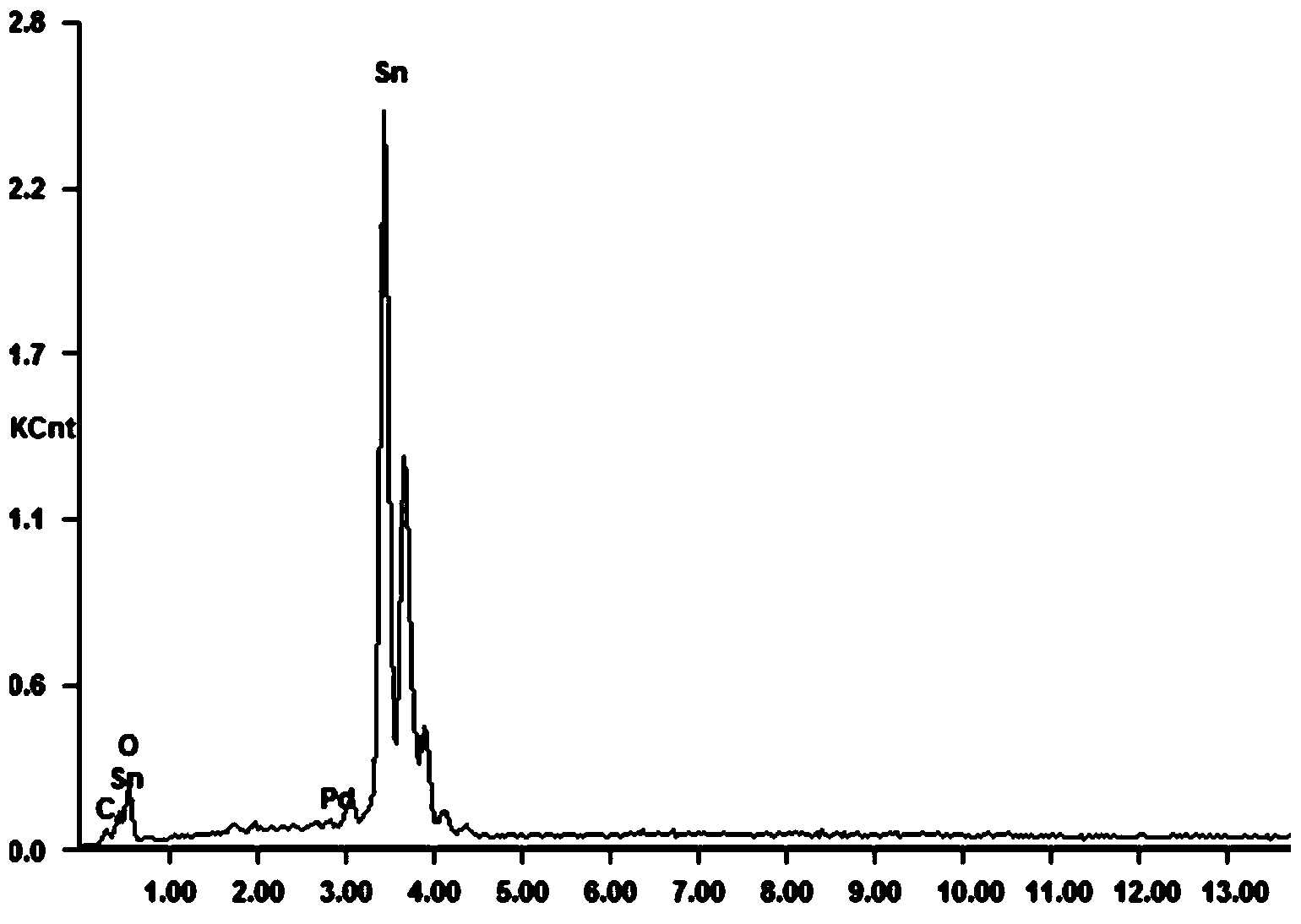

[0035] Ultrasonically disperse carbon nanotubes in ultrapure water for 20 minutes, add tin tetrachloride pentahydrate precursor and ultrasonically disperse, then add sodium chloropalladate solution (the molar ratio of Pd / Sn is 1%) to adjust the pH value to 8, magnetically stirred at 60-90°C for 6h to obtain a milky white sol, washed, dried, calcined at 200°C and kept for 24h to prepare palladium-doped tin dioxide-coated carbon nanotubes (Pd / SnO 2 / CNT).

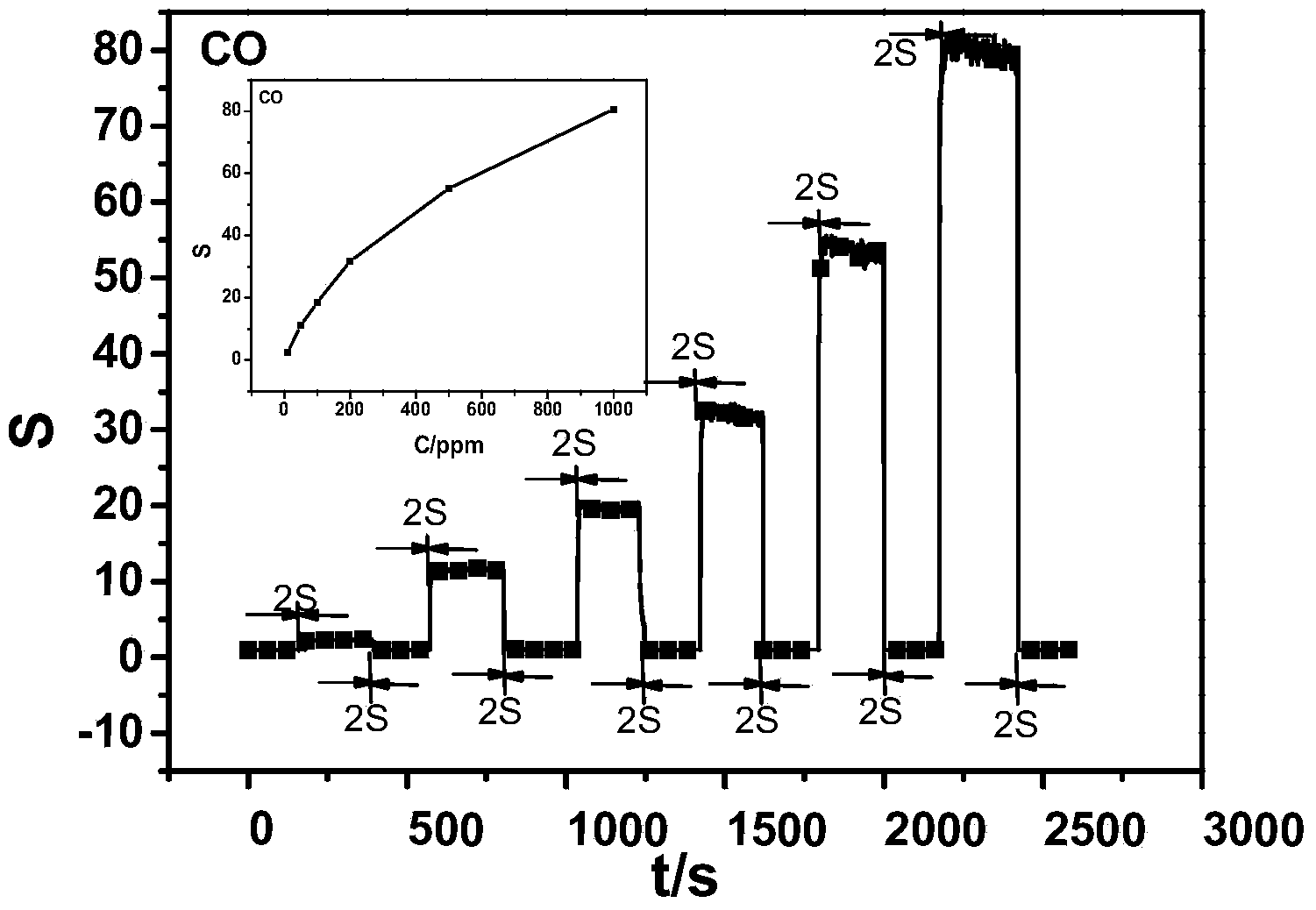

[0036] Take a certain amount of Pd / SnO 2 / CNT is placed in an agate mortar, added an appropriate amount of deionized water and ground into a uniform and fine slurry, and then coated on the gold finger electrode based on aluminum oxide, and the gas sensor is prepared by coating. The sensing layer is about 100um, dried in the shade after coating, and then placed in a gas sensor tester, assembled into a complete circuit to form a complete gas sensing device, and aged for 24 hours. Testing its gas-sensing performance shows that...

Embodiment 2

[0039] Ultrasonically disperse carbon nanotubes in ultrapure water for 20 minutes, add tin tetrachloride pentahydrate precursor and ultrasonically disperse, then add sodium chloropalladate solution (the molar ratio of Pd / Sn is 3%) to adjust the pH value to 8, magnetically stirred at 60-90°C for 6h to obtain a milky white sol, washed, dried, calcined at 200°C and kept for 24h to prepare palladium-doped tin dioxide-coated carbon nanotubes (Pd / SnO 2 / CNT).

[0040] Take a certain amount of Pd / SnO 2 / CNT is placed in an agate mortar, added an appropriate amount of deionized water and ground into a uniform and fine slurry, and then coated on the gold finger electrode based on aluminum oxide, and the gas sensor is prepared by coating. The sensing layer is about 100um, dry it in the shade after painting, then put it in the gas sensor tester, assemble it into a complete circuit, form a complete gas sensing device, age the current for 24 hours, and set it aside.

[0041] performance ...

Embodiment 3

[0043] Ultrasonic dispersion of carbon nanotubes in ultrapure water for 20 min, adding tin tetrachloride pentahydrate precursor and ultrasonic dispersion, then adding sodium chloropalladate solution (Pd accounted for Pd / SnO 2 / CNT mass fraction is 1wt%), adjust the pH value to 7, stir magnetically at 30°C for 36h to obtain a milky white sol, wash, dry, calcinate at 700°C and keep warm for 1h to prepare palladium-doped tin dioxide-coated carbon nano tube (Pd / SnO 2 / CNT).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com