Smokeless mosquito coil

A technology of mosquito coils and plant extracts, applied in the direction of insecticides, animal repellents, botanical equipment and methods, etc., can solve problems affecting the mosquito repellent effect, and achieve benefits to human health and air environmental protection, low price, Good flame retardant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

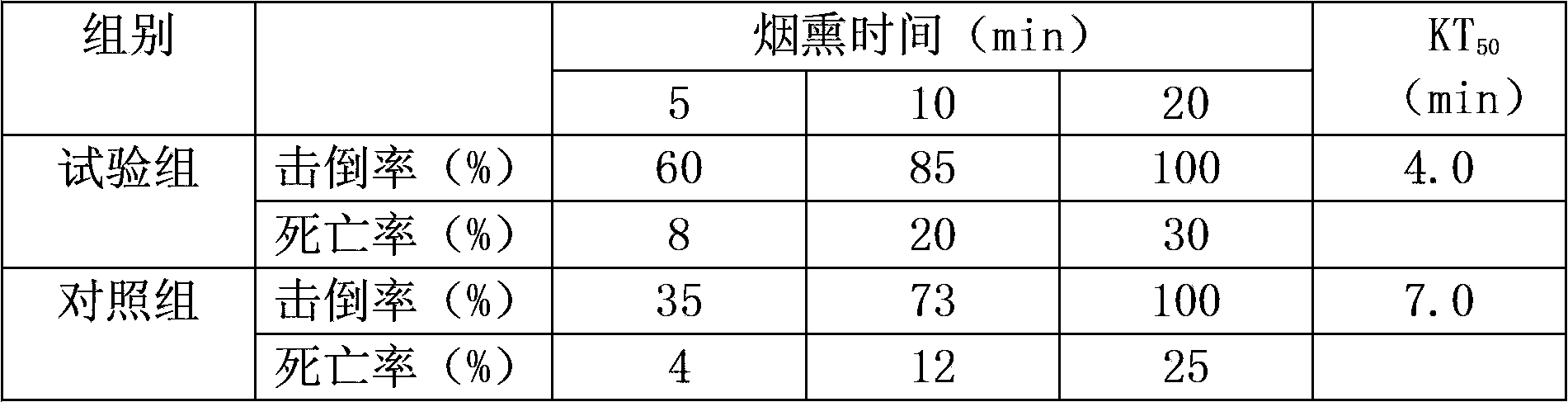

Image

Examples

Embodiment 1

[0024] 1) Take the mixture of wood residue, coal cinder, sand and gravel and grind it into 80 mesh ash powder after calcining;

[0025] 2) Take 4kg Artemisia argyi and 2kg Huang Hua Song and crush them into 80 mesh fine powder, put them in a container, add 36L of water, decoct at 70°C for 0.5 hours, filter, and concentrate the filtrate to an extract with a relative density of 1.0, which is the plant Extract;

[0026] 3) Take 40kg of charcoal powder, 20kg of ash powder, 6kg of starch, and 0.2kg of plant extract for subsequent use;

[0027] 4) Mix charcoal powder and ash powder fully to obtain dry material;

[0028] 5) Take α-starch and add water to gelatinize, mix with dry material evenly to obtain wet material;

[0029] 6) Extrude the wet material into a blank, then punch it into a spiral billet shape, and bake it at 60°C for 6 hours to obtain a dry billet;

[0030] 7) The plant extract is evenly attached to the dry mosquito coil, which is the smokeless mosquito coil.

Embodiment 2

[0040] 1) Take the mixture of wood slag, cinder, sand and gravel and grind it into 150 mesh ash powder after calcining;

[0041] 2) Take 11kg of mugwort leaves and 7kg of Huanghuasong and crush them into 150 mesh fine powder, put them in a container, add 144L of water, decoct at 90°C for 2.5 hours, filter, and concentrate the filtrate to an extract with a relative density of 1.2, which is the plant Extract;

[0042] 3) Take 75kg of charcoal powder, 45kg of ash powder, 18kg of starch, and 0.5kg of plant extract for subsequent use;

[0043] 4) Mix charcoal powder and ash powder fully to obtain dry material;

[0044] 5) Take α-starch and add water to gelatinize, mix with dry material evenly to obtain wet material;

[0045] 6) Extrude the wet material into a blank, then punch it into a spiral billet shape, and bake it at 70°C for 7 hours to obtain a dry billet;

[0046] 7) The plant extract is evenly attached to the dry mosquito coil, which is the smokeless mosquito coil.

Embodiment 3

[0048] 1) Take the mixture of wood slag, cinder, sand and gravel and grind it into 120 mesh ash powder after calcining;

[0049] 2) Take 9kg Artemisia argyi and 5kg Huanghuasong and crush them into 120 mesh fine powder, put them in a container, add 98L of water, decoct at 80°C for 1.5 hours, filter, and concentrate the filtrate to an extract with a relative density of 1.1, which is the plant Extract;

[0050] 3) Take 60kg of charcoal powder, 30kg of ash powder, 12kg of starch, and 0.35kg of plant extract for subsequent use;

[0051] 4) Mix charcoal powder and ash powder fully to obtain dry material;

[0052] 5) Take α-starch and add water to gelatinize, mix with dry material evenly to obtain wet material;

[0053] 6) Extrude the wet material into a blank, then punch it into a spiral billet shape, and bake it at 65°C for 6.5 hours to obtain a dry billet;

[0054] 7) The plant extract is evenly attached to the dry mosquito coil, which is the smokeless mosquito coil.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com