Processing technology for sterilization, deodorization, dehydration and heavy metal removing of sludge

A technology for heavy metal removal and treatment process, applied in water/sludge/sewage treatment, sludge treatment, chemical instruments and methods, etc., can solve the problems of high energy consumption, secondary pollution of the environment, high bacterial content, etc., and achieve energy consumption The effect of low cost, low cost and short process time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

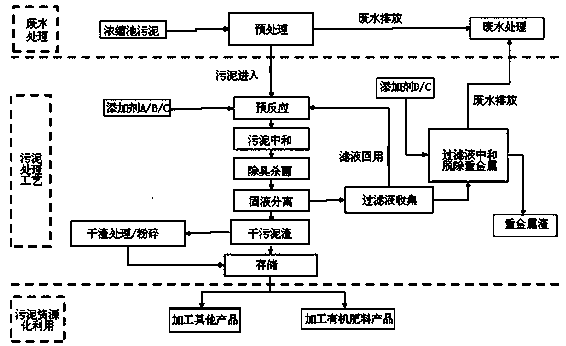

[0020] see figure 1 , in an embodiment of the present invention, a treatment process for sterilizing, deodorizing, dehydrating, and removing heavy metals from sludge comprises the following steps:

[0021] (1) Thickening tank sludge pretreatment: take concentrated sludge with a moisture content of 97% for pretreatment to obtain primary sludge with a moisture content of 75%, to achieve the purpose of preliminary sterilization of sludge, release of cell water, deodorization, and removal of heavy metals , and increase the fluidity of the sludge to facilitate the next step of treatment;

[0022] (2) Primary sludge pre-reaction: Add water, 93% industrial grade sulfuric acid or nitric acid and 27.5% industrial hydrogen peroxide to the primary sludge in sequence, and stir for 10 minutes to make a slurry; The mass ratio of water, sulfuric acid or nitric acid, hydrogen peroxide to primary sludge is 0.2:0.02:0.02:1;

[0023] (3) Sludge neutralization: Add industrial-grade sodium hydro...

Embodiment 2

[0028] see figure 1 , in an embodiment of the present invention, a treatment process for sterilizing, deodorizing, dehydrating, and removing heavy metals from sludge comprises the following steps:

[0029] (1) Thickening tank sludge pretreatment: Take the concentrated sludge with a moisture content of 98% for pretreatment to obtain the primary sludge with a moisture content of 80%, so as to achieve the purpose of preliminary sterilization of sludge, release of cell water, deodorization, and removal of heavy metals , and increase the fluidity of the sludge to facilitate the next step of treatment;

[0030] (2) Primary sludge pre-reaction: Add water, 95% industrial grade sulfuric acid or nitric acid and 30% industrial hydrogen peroxide to the primary sludge in sequence, and stir for 20 minutes to make a slurry; The mass ratio of water, sulfuric acid or nitric acid, hydrogen peroxide to primary sludge is 0.6:0.06:0.06:1;

[0031] (3) Sludge neutralization: Add industrial-grade ...

Embodiment 3

[0036] see figure 1 , in an embodiment of the present invention, a treatment process for sterilizing, deodorizing, dehydrating, and removing heavy metals from sludge comprises the following steps:

[0037] (1) Thickening tank sludge pretreatment: Take the concentrated sludge with a moisture content of 99.5% for pretreatment to obtain primary sludge with a moisture content of 85%, so as to achieve the purpose of preliminary sterilization of sludge, release of cell water, deodorization, and removal of heavy metals , and increase the fluidity of the sludge to facilitate the next step of treatment;

[0038] (2) Primary sludge pre-reaction: Add water, 98% industrial grade sulfuric acid or nitric acid and 35% industrial hydrogen peroxide to the primary sludge in sequence, and stir for 30 minutes to make a slurry; The mass ratio of water, sulfuric acid or nitric acid, hydrogen peroxide to primary sludge is 1:0.1:0.1:1;

[0039] (3) Sludge neutralization: Add industrial-grade sodium...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com