Oxyfluoride glass with low hydroxyl content and preparation method of oxyfluoride glass

A technology of oxyfluoride glass and low hydroxyl group, which is applied in the field of oxyfluoride glass with low hydroxyl group content and its preparation, and can solve the problems of low glass transition temperature, low water resistance and mechanical strength, large hydroxyl group absorption peak, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Composition is as shown in 1# in table 1, and concrete preparation process is as follows:

[0025] According to the molar percentage of the 1# glass composition in Table 1, calculate the weight of the corresponding components, weigh the raw materials and mix them evenly; put the mixture into a platinum crucible and melt it in a silicon carbide rod electric furnace at 900°C to 950°C , clarify for 15 minutes after complete melting, pour the molten glass into a preheated mold; quickly move the glass into a muffle furnace that has been heated to a specific annealing temperature, keep it warm for 4 hours, and then lower it to room temperature at a rate of 10°C / hour , and remove the glass sample after complete cooling.

[0026] The test results for this glass are as follows:

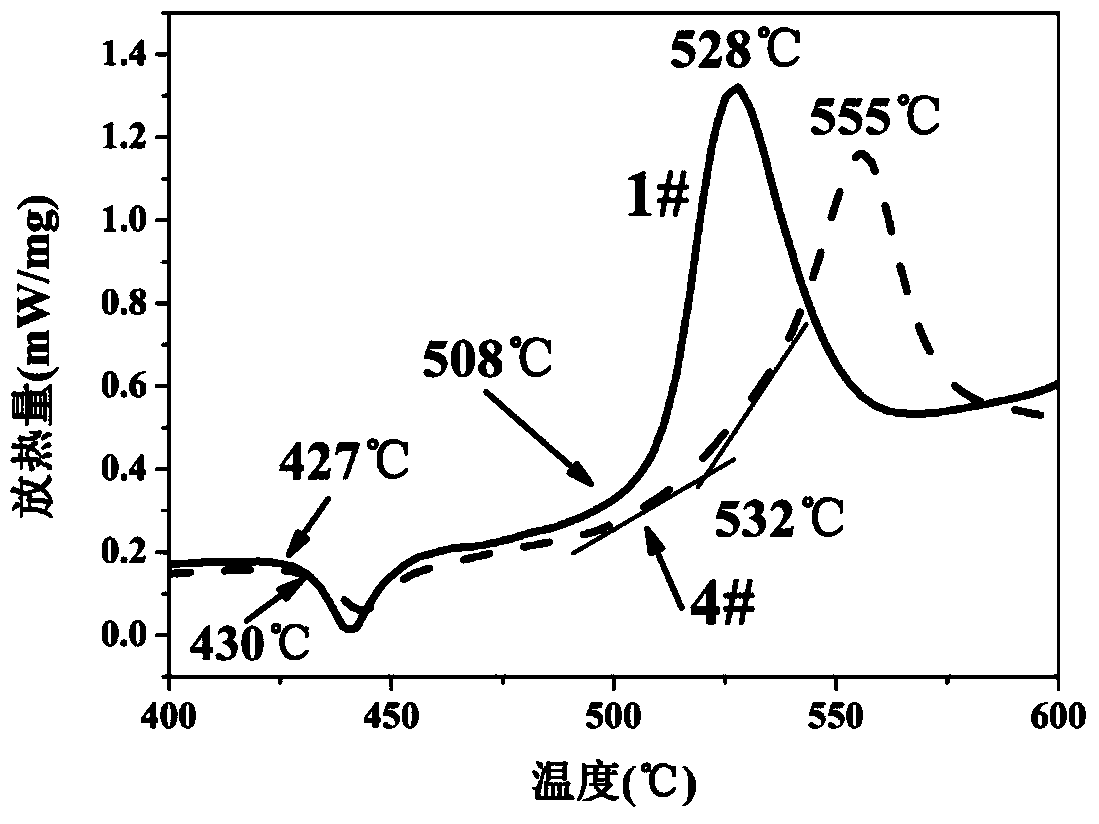

[0027] Take a small sample after annealing, grind it into a fine powder with an agate mortar, and conduct a differential thermal analysis test.

[0028] Process the annealed sample into a glass sheet ...

Embodiment 2

[0030] Composition is as shown in 2# in table 1, and concrete preparation process is as embodiment 1 #

[0031] The test results for this glass are as follows:

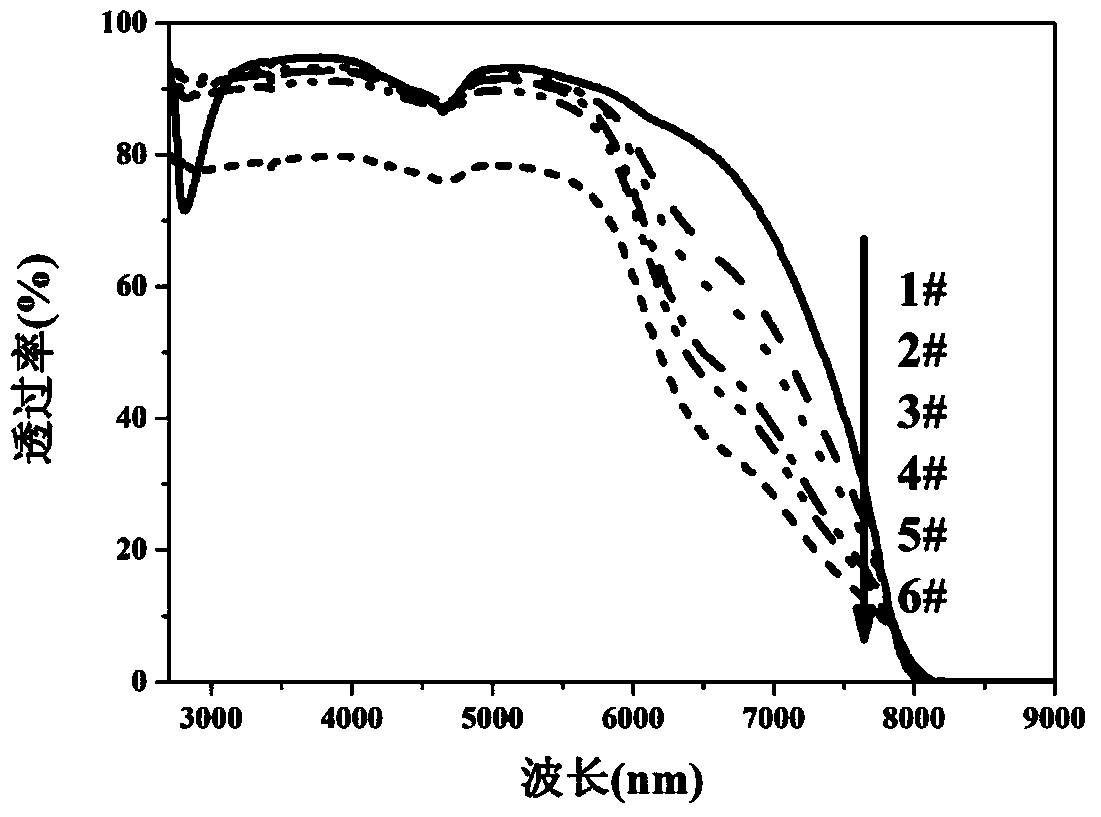

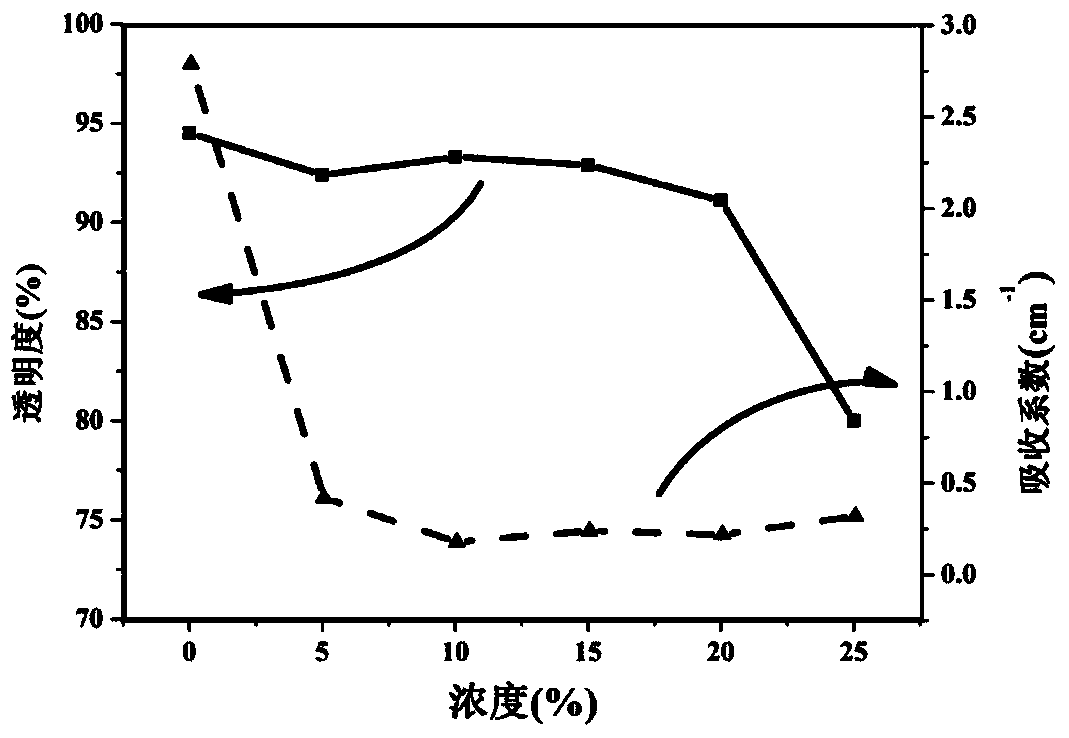

[0032] Process the annealed sample into a glass sheet of 10×20×1.0mm and polish it, and test its infrared transmission spectrum. The infrared transmission spectrum of the oxyfluoride glass embodiment 2# of low hydroxyl content of the present invention is as follows figure 1 As shown, the maximum transmittance and 3μm absorption coefficient are as figure 2 shown. Experiments show that the glass has good transparency, no crystallization, a slightly reduced range of mid-infrared light transmission, and a maximum transmittance of 93%. There is a weak hydroxyl absorption peak at 2.9 μm, and the hydroxyl coefficient is small.

Embodiment 3

[0034] Composition is as shown in 3# in table 1, and concrete preparation process is as embodiment 1 #

[0035] The test results for this glass are as follows:

[0036] Process the annealed sample into a glass sheet of 10×20×1.0mm and polish it, and test its infrared transmission spectrum. The infrared transmission spectrum of the oxyfluoride glass embodiment 3# of low hydroxyl content of the present invention is as follows figure 1 As shown, the maximum transmittance and 3μm absorption coefficient are as figure 2 shown. Experiments show that the glass has good transparency, no crystallization, a slightly reduced range of mid-infrared light transmission, and a maximum transmittance of 92%. There is a weak hydroxyl absorption peak at 2.9 μm, and the hydroxyl coefficient is small.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com