Efficient concrete water reducer and preparation method thereof

A concrete water-reducing agent and high-efficiency technology, applied in the field of high-efficiency concrete water-reducing agent and its preparation, can solve the problems of low slump loss, high water reduction rate, poor compoundability, etc., and achieve low slump loss and cost Low, high bleed air effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

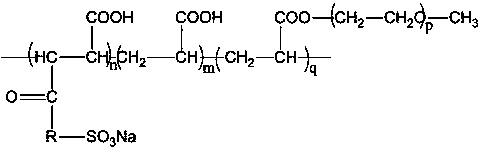

[0024] A multifunctional concrete water reducing agent of the present invention has the following structure:

[0025]

[0026] In the formula, R is a lignin structure, n is an integer of 2-10, m is an integer of 2-10, q is an integer of 2-10, and p is an integer of 5-20.

[0027] Synthesized by the following steps:

[0028] (1) Add maleic anhydride and sodium lignosulfonate to the reaction kettle at a mass ratio of 1:100, turn on the heating and stirring, heat to 120°C, add maleic anhydride and sodium lignosulfonate with a total weight of 0.5 % concentrated sulfuric acid, keep the temperature at 120±5°C, and react for 7 hours.

[0029] (2) Add the above-mentioned maleic anhydride graft modified lignosulfonate and acrylic acid, polyoxyethylene monomethyl ether acrylate into the reaction kettle according to the ratio of 1:1:1 by mass, add pure water as solvent, and stir Heat to 80°C, add dropwise a 10% azobisisobutyl ether hydrochloride aqueous solution with 0.5% of the tot...

Embodiment 2

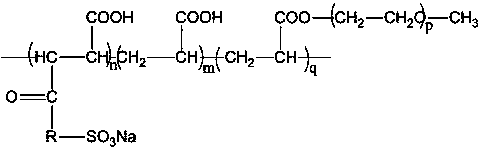

[0031] A multifunctional concrete water reducing agent of the present invention has the following structure:

[0032]

[0033] In the formula, R is a lignin structure, n is an integer of 2-10, m is an integer of 2-10, q is an integer of 2-10, and p is an integer of 5-20.

[0034] Synthesized by the following steps:

[0035] (1) Add maleic anhydride and sodium lignosulfonate into the reaction kettle according to the mass ratio of 1:200, turn on the heating and stirring, heat to 130°C, add maleic anhydride and sodium lignosulfonate with a total weight of 0.8 % concentrated sulfuric acid, keep the temperature at 130±5°C, and react for 5 hours.

[0036] (2) Add maleic anhydride graft-modified lignosulfonate, acrylic acid and polyoxyethylene monomethyl ether acrylate to the reaction kettle according to the mass ratio of 1:0.5:0.5, add pure water as solvent, and stir Heat to 80°C, add dropwise 10% benzoyl peroxide aqueous solution with 1.0% of the total monomer mass, dropwise f...

Embodiment 3

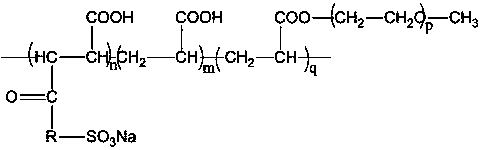

[0038] A multifunctional concrete water reducing agent of the present invention has the following structure:

[0039]

[0040] In the formula, R is a lignin structure, n is an integer of 2-10, m is an integer of 2-10, q is an integer of 2-10, and p is an integer of 5-20.

[0041] Synthesized by the following steps:

[0042] (1) Add maleic anhydride and sodium lignosulfonate to the reaction kettle at a mass ratio of 1:50, turn on the heating and stirring, heat to 100°C, add maleic anhydride and sodium lignosulfonate with a total weight of 1.0 % of p-toluenesulfonic acid, keep the temperature at 100±5℃, and react for 5h.

[0043] (2) Add maleic anhydride graft-modified lignosulfonate, acrylic acid and polyoxyethylene monomethyl ether acrylate to the reaction kettle according to the mass ratio of 1:1.5:1, add pure water as solvent, and stir Heat to 70°C, add dropwise 10% ammonium persulfate aqueous solution with 1.2% total monomer mass, dropwise addition is completed after 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com