Method for preparing nano-copper/epoxy resin composite material

A technology of epoxy resin and composite materials, applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problems of low mechanical properties, poor dispersion, easy agglomeration of nano copper powder, etc. Good performance, improved mechanical properties and dimensional stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

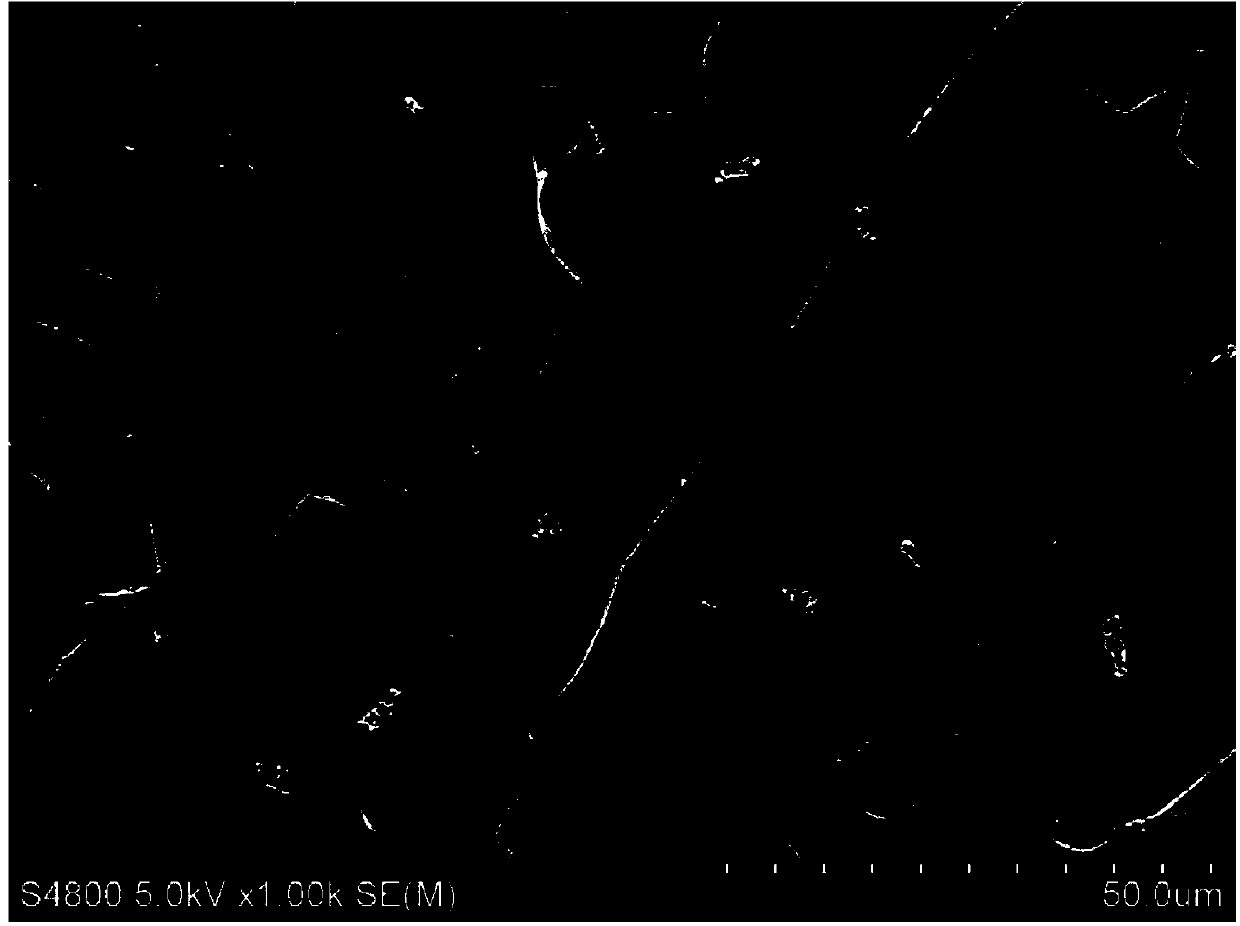

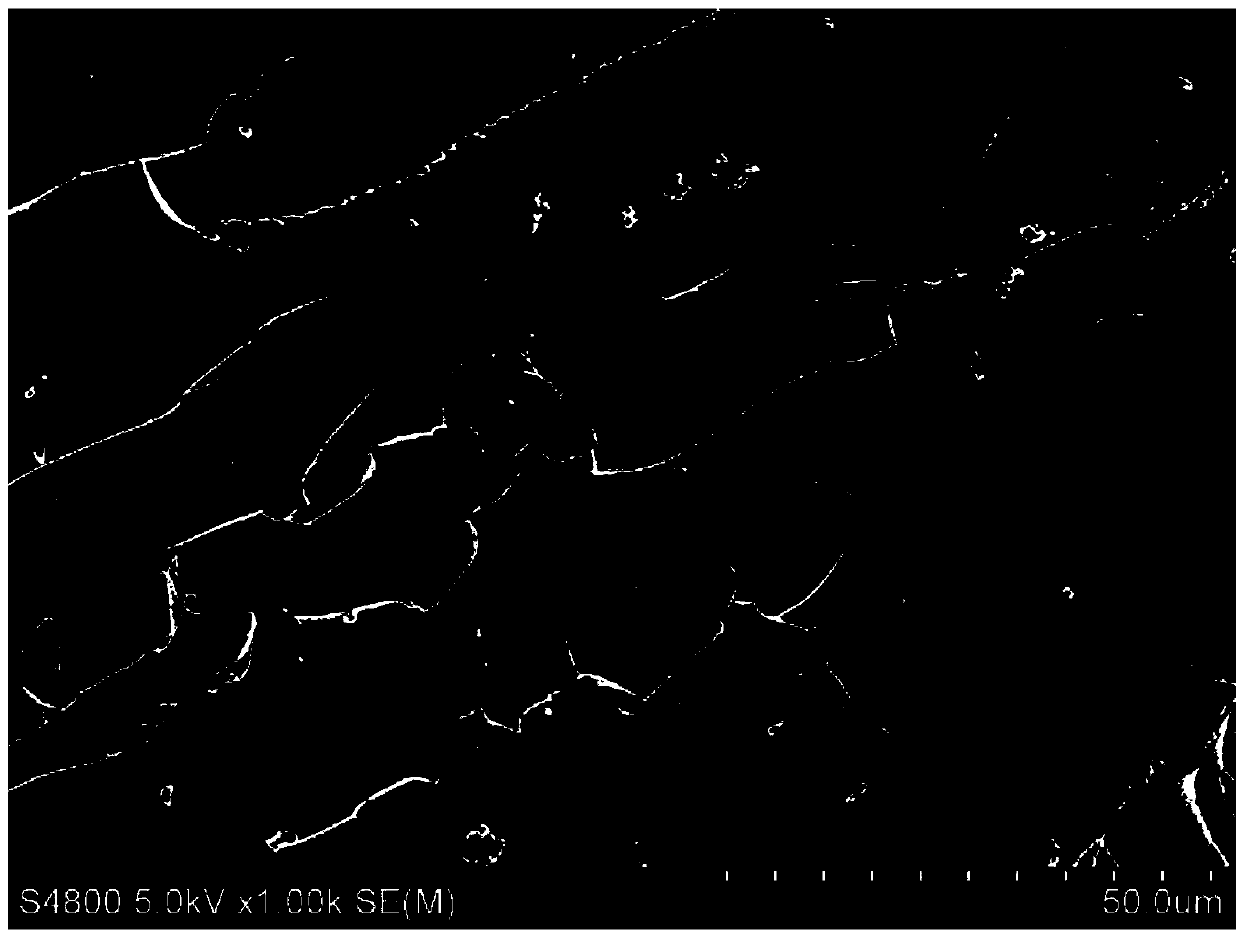

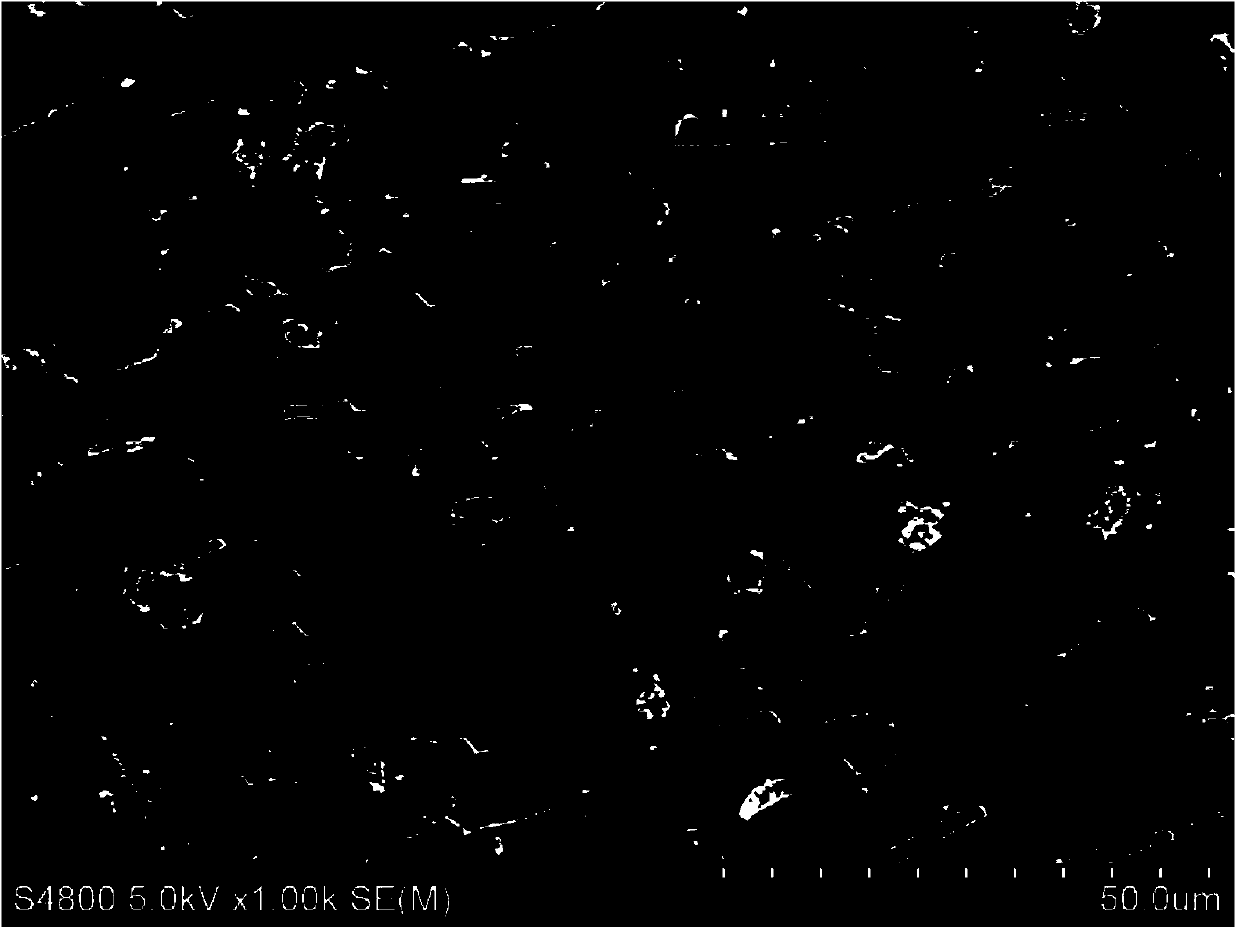

Image

Examples

specific Embodiment approach 1

[0024] Specific implementation mode one: this implementation mode is a kind of preparation method of nano-copper / epoxy resin composite material and is specifically completed according to the following steps:

[0025] 1. Preparation of nano-copper powder: ① Use distilled water as solvent at room temperature, and use ultrasonic method to dissolve CuSO 4 ·5H 2 O is completely dissolved to give CuSO 4 aqueous solution; ② to the CuSO obtained in step ① 4 Add polyvinylpyrrolidone to the aqueous solution, and sonicate for 30 to 50 minutes to obtain polyvinylpyrrolidone / CuSO 4 mixed aqueous solution; 3. mix hydrazine hydrate and distilled water at room temperature to obtain a hydrazine hydrate solution; 4. use distilled water as a solvent at room temperature, and dissolve NaOH completely to obtain NaOH solution; CuSO 4 Add the mixed aqueous solution into a three-necked round-bottomed flask, then add the hydrazine hydrate solution obtained in step one (3) to the three-necked round-...

specific Embodiment approach 2

[0041] Specific embodiment two: the difference between this embodiment and specific embodiment one is: the CuSO described in step one 1. 4 ·5H 2 The volume ratio of O mass to distilled water is (0.15g-0.2g): 1mL. Other steps are the same as in the first embodiment.

specific Embodiment approach 3

[0042] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is: the quality of polyvinyl pyrrolidone described in step 2. and CuSO 4 The volume ratio of the aqueous solution is (0.015g-0.025g): 1mL. Other steps are the same as those in Embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Elastic modulus | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com