Alumina composite material and preparation method thereof, copper clad substrate

A composite material and alumina technology, which is applied in the field of composite material preparation, can solve problems such as clusters and limit the application of alumina composite materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

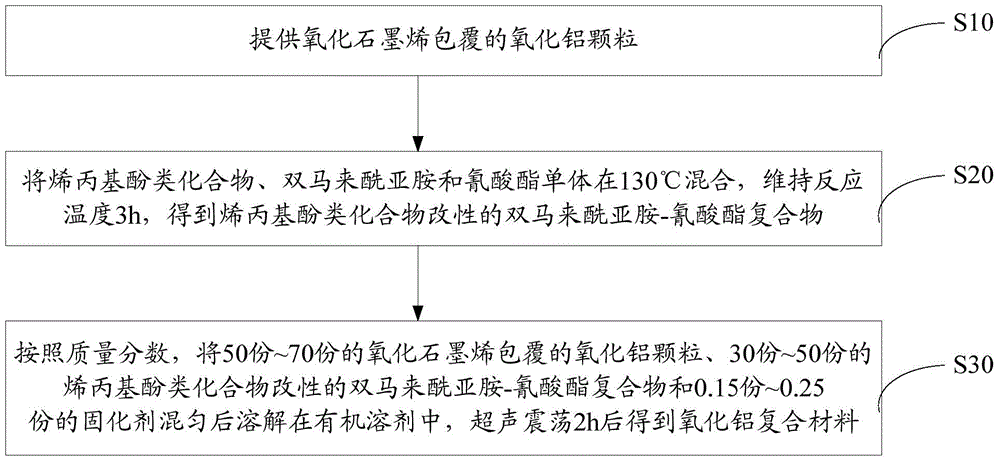

[0051] Such as figure 1 The preparation method of the alumina composite material shown in one embodiment includes the following steps:

[0052] S10, providing alumina particles coated with graphene oxide.

[0053] The alumina particles coated with graphene oxide can be prepared by the following method:

[0054] Add alumina particles with a particle size of 200nm to 3μm into the solvent, ultrasonically disperse them and add them to an oil bath, heat up to 90°C, add surface modifier, then stir and heat up to 115°C for 4 hours, cool and filter and retaining the filter residue; washing the filter residue and drying it, then adding the dried filter residue into the graphene oxide aqueous solution under stirring, stirring for 3 hours, and centrifuging to obtain graphene oxide-coated alumina particles.

[0055] The particle size of the aluminum oxide particles is 200 nm to 3 μm.

[0056] The mass ratio of graphene oxide to alumina particles is 1-2:100.

[0057] The solvent can be...

Embodiment 1

[0082] (1) Preparation of alumina particles coated with graphene oxide.

[0083] Add 30mL of xylene and 10.0g of alumina with a particle size of 200nm into a three-neck flask, ultrasonically disperse for 10min, put it into an oil bath, stir the solution magnetically and raise the temperature to 90°C. Add 0.80 g of the surface modifier γ-aminopropyltriethoxysilane dropwise with a dropper, raise the temperature to 115° C. after the dropwise addition, keep magnetic stirring, and react for 4 hours.

[0084] Cool the mixed solution, pour it into a suction filter funnel while it is hot, wash the sample obtained by suction filtration twice with ethanol, and put it in a vacuum drying oven for 6 hours at 150°C to obtain γ-aminopropyltriethoxysilane-alumina.

[0085] Add 50 mL of graphene oxide aqueous solution and 10 mL of ultrapure water into a three-necked flask, stir and mix evenly, and then add 10.0 g of γ-aminopropyltriethoxysilane-alumina. The solution was magnetically stirred a...

Embodiment 2

[0098] The preparation method is the same as in Example 1, the only difference being that the particle size of alumina used in step (1) is 3 μm; adding 0.20 g of surface modifier γ-aminopropyltriethoxysilane; Stir for 2h.

[0099]The prepared copper-clad substrate includes a first electrode layer, a dielectric layer and a second electrode layer stacked in sequence, wherein the first electrode layer and the second electrode layer are copper foil sheets with a thickness of 35 microns, and the dielectric layer consists of two prepregs composition, with a thickness of 70 microns. The thermal conductivity of the substrate material is 1.5W / m·K, the dielectric loss is 0.025 (1.0MHz), and the dielectric constant is 3.9 (1.0MHz).

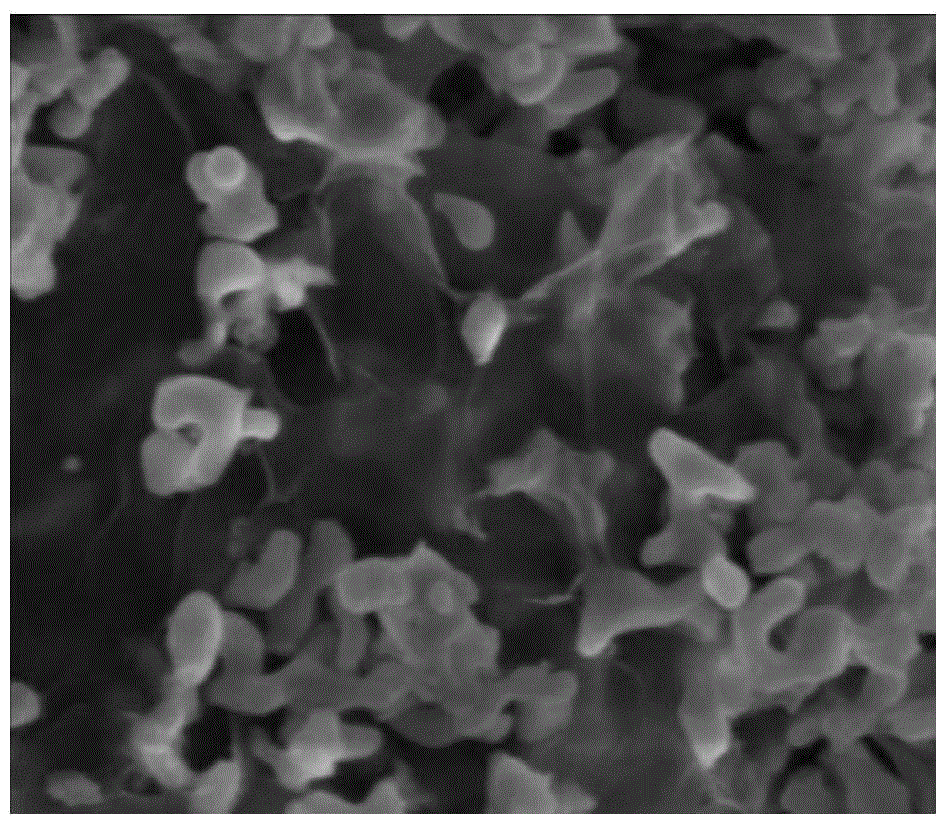

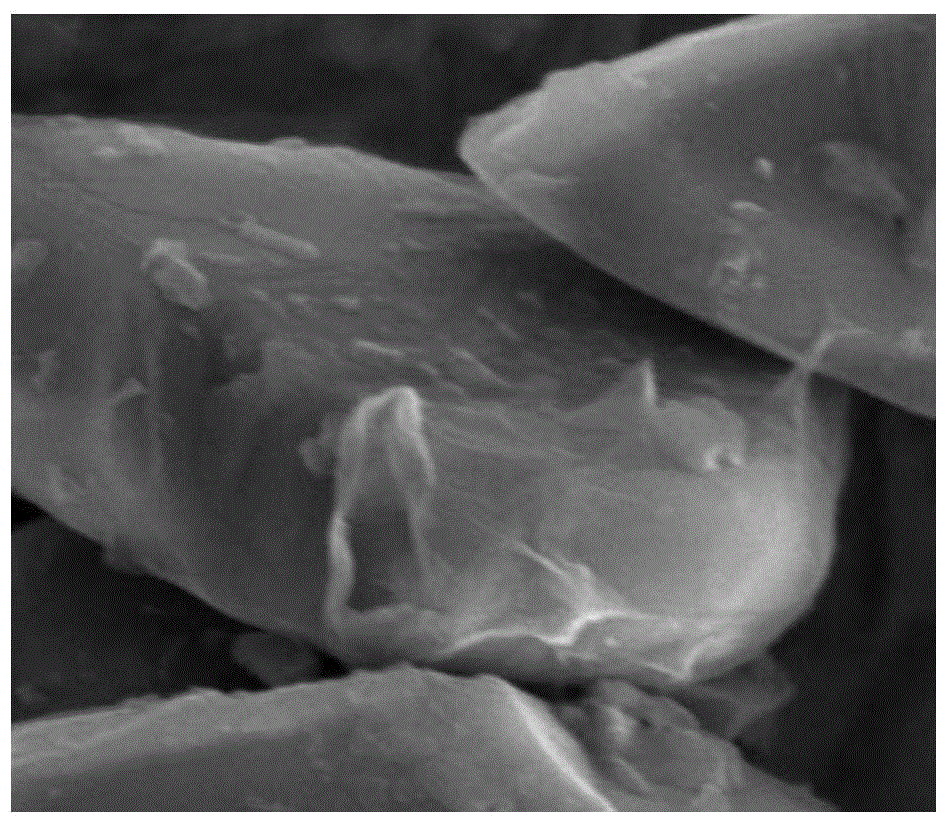

[0100] image 3 The SEM photo of the alumina particles coated with graphene oxide prepared in this embodiment is obtained by image 3 It can be seen that graphene oxide is coated on the surface of alumina particles, and graphene oxide acts as a bridge to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com