Sludge-crop straw joint disposal method based on fast pyrolysis

A technology for crop straw and treatment method, which is applied in the field of co-processing of sludge and crop straw, can solve the problems of resource waste, unreachable heavy metal content, random disposal of straw, etc., achieve balanced nutritional components, reduce operating costs, and increase relative yield Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

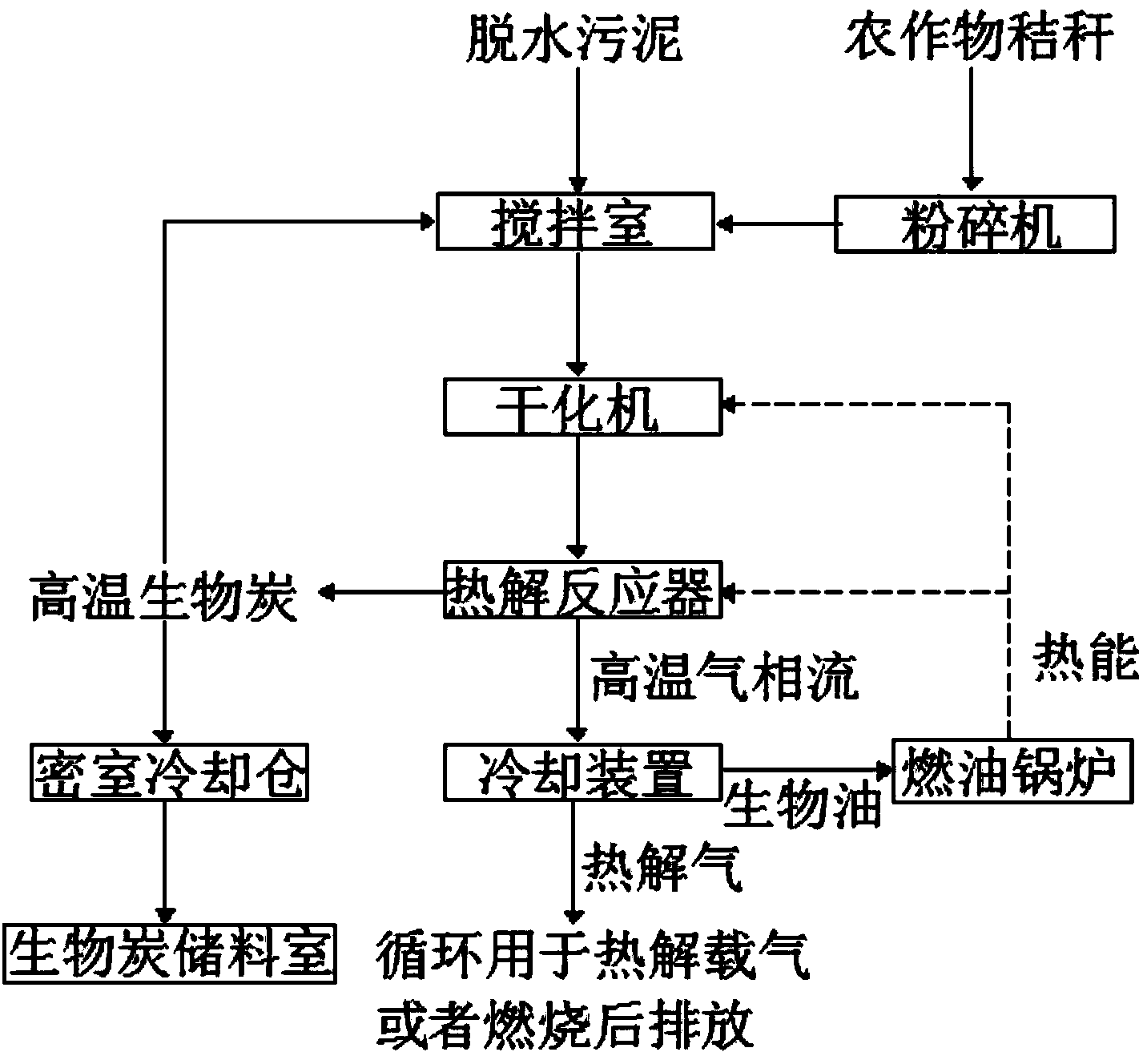

Image

Examples

Embodiment 1

[0030] A method for co-processing sludge and crop residues based on rapid pyrolysis, including the following steps:

[0031] Step 1: Transport the dried crop stalks to a pulverizer to crush them into straw powder with a length of 1mm, and then transport the straw powder to the mixing chamber;

[0032] Step 2: Transport dewatered sludge with a moisture content of 70 to 85% to the mixing chamber in step 1, and mix and stir the dewatered sludge and straw powder in step 1 at a weight ratio of 1:1 to obtain a mixture;

[0033] Step 3: Transport the mixed material obtained in step 2 to a drying machine for drying treatment, and then transport the dried mixed material to a pyrolysis reactor for rapid pyrolysis treatment. The pyrolysis of the mixed material rapid pyrolysis treatment The temperature is 420°C, and the residence time of the mixture in the pyrolysis reactor is 10 minutes. The rapid pyrolysis treatment of the mixture in the pyrolysis reactor will output high-temperature ga...

Embodiment 2

[0037] A method for co-processing sludge and crop residues based on rapid pyrolysis, including the following steps:

[0038] Step 1: Transport the dried crop straw to a pulverizer to crush it into straw powder with a length of 2mm, and then transport the straw powder to the mixing chamber;

[0039] Step 2: transport the dewatered sludge with a moisture content of 70-85% to the mixing chamber in step 1, and mix and stir the dewatered sludge and the straw powder in step 1 at a weight ratio of 3:1 to obtain a mixture;

[0040] Step 3: Transport the mixed material obtained in step 2 to a drying machine for drying treatment, and then transport the dried mixed material to a pyrolysis reactor for rapid pyrolysis treatment. The pyrolysis of the mixed material rapid pyrolysis treatment The temperature is 600°C, and the residence time of the mixture in the pyrolysis reactor is 40 minutes. The rapid pyrolysis treatment of the mixture in the pyrolysis reactor will output high-temperature ...

Embodiment 3

[0044] A method for co-processing sludge and crop residues based on rapid pyrolysis, including the following steps:

[0045] Step 1: transport the dried crop stalks to a pulverizer to crush them into straw powder with a length of 3 mm, and then transport the straw powder to the mixing chamber;

[0046] Step 2: transport the dewatered sludge with a moisture content of 70 to 85% to the mixing chamber in step 1, and mix and stir the dewatered sludge and the straw powder in step 1 at a weight ratio of 2:1 to obtain a mixture;

[0047] Step 3: Transport the mixed material obtained in step 2 to a drying machine for drying treatment, and then transport the dried mixed material to a pyrolysis reactor for rapid pyrolysis treatment. The pyrolysis of the mixed material rapid pyrolysis treatment The temperature is 480°C, and the residence time of the mixture in the pyrolysis reactor is 15 minutes. The rapid pyrolysis treatment of the mixture in the pyrolysis reactor will output high-tempe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com