The method of using pet to produce flat yarn

A flat yarn and weight technology, which is applied in stretch spinning, rayon manufacturing, filament/thread forming, etc., can solve the problems of insufficient flat yarn strength, poor toughness, easy breakage, etc., and achieve improved drawing performance and rigidity Large, the effect of improving melt strength and toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

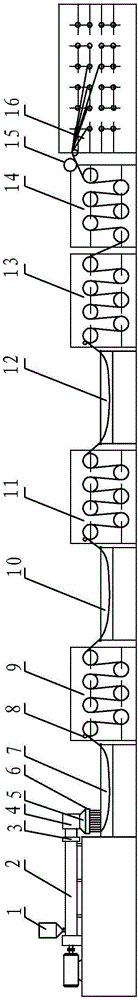

[0021] Example 1: Combining figure 1 shown, including the following steps:

[0022] (1) Dry the PET at 140°C for 6 hours to remove water, and mix it with the toughening agent MG-801 (a vinyl elastomer bifunctionalized with acrylate and glycidyl ester, Hangzhou Qitai Plastic Materials) in a certain proportion Co., Ltd.), anti-hydrolysis agent HyMax1010 (for monomeric carbodiimide, provided by Shanghai Langyi Functional Materials Co., Ltd.), antioxidant IRGANOX1010 (tetra[β-(3,5-di-tert-butyl-4- Hydroxyphenyl) propionic acid] pentaerythritol ester, Zhejiang Jinhai Chemical Company), sodium benzoate were mixed in a high-speed mixer. MG-801 is 1.5% of the mass of PET raw material, HyMax1010 is 0.5% of the mass of PET raw material, IRGANOX1010 is 0.1% of the mass of PET raw material, and sodium benzoate is 0.3% of the mass of PET raw material.

[0023] (2) Under the condition of 260-285°C, the mixed PET is added from the hopper 1 and melt-blended in the twin-screw extruder 2, so ...

Embodiment 2

[0032] (1) Dry the PET at 160°C for 4 hours to remove water, and mix it with toughening agent MG-801, anti-hydrolysis agent HyMax1010, antioxidant IRGANOX168 (tris(2,4-di-tert-butyl phosphite) in a certain proportion phenyl) ester, Zhejiang Jinhai Chemical Company), nucleating agent sodium benzoate, etc. were mixed in a high-speed mixer. MG-801 is 2% of the mass of PET raw material, HyMax1010 is 0.3% of the mass of PET raw material, IRGANOX168 is 0.2% of the mass of PET raw material, and sodium benzoate is 0.3% of the mass of PET raw material.

[0033] (2) Under the condition of 260-290°C, the mixed PET is melt-blended in a twin-screw extruder, so that a certain reaction occurs in the barrel, and the aspect ratio of the screw is 36:1.

[0034] (3) Adjust the screw speed and melt pump speed according to the production process, so that the PET in the molten state is evenly and continuously conveyed to the extruder head, and then extrude multiple primary filaments with a diameter...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com