A flue gas denitrification device

A flue gas and denitrification technology, applied in waste heat treatment, lighting and heating equipment, furnace components, etc., can solve the problems of reducing denitration efficiency, high operating cost, large dust content, etc., to improve mixing uniformity and meet environmental protection requirements , the effect of improving the denitration efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

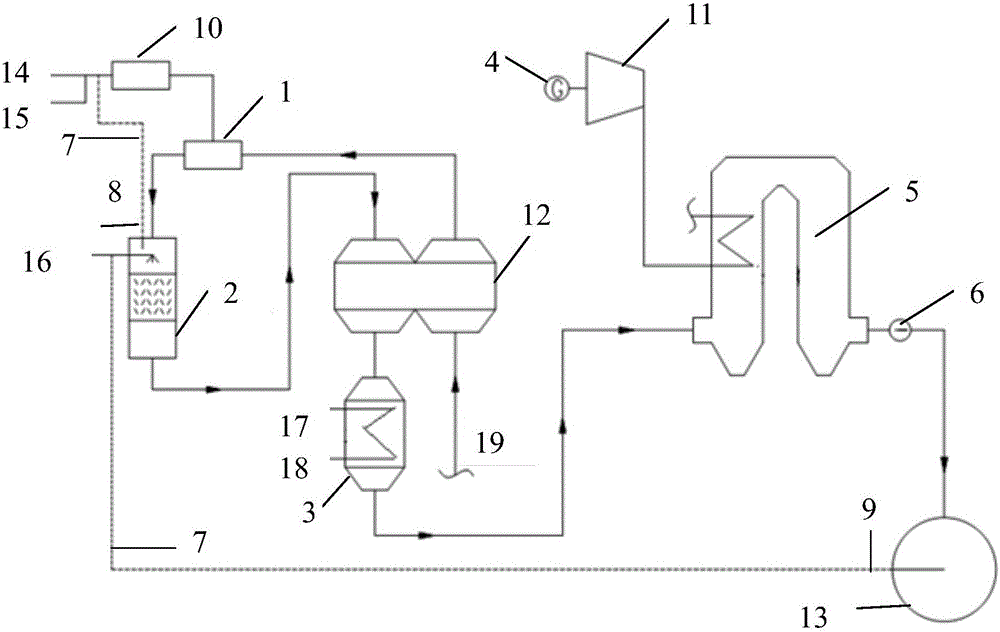

[0035] In order to make the technical problems, technical solutions and advantages to be solved by the invention clearer, the following will describe in detail with reference to the drawings and specific embodiments.

[0036] The present invention is aimed at denitrification by selective catalytic reduction method (SCR method) of glass kiln flue gas which is currently available. The dust content in glass kiln flue gas is large and the cohesiveness is strong, which easily leads to catalyst poisoning and failure, which seriously reduces denitrification efficiency; SCR method denitrification The operating cost is high; the temperature of the flue gas from the glass kiln decreases after passing through the SCR denitrification system, which affects the waste heat utilization rate and power generation. A flue gas denitrification device is provided.

[0037] Such as figure 1 As shown, the embodiment of the present invention provides a flue gas denitrification device, including:

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com