End surface welding cylindrical lithium battery

A cylindrical, end-face welding technology, applied in lithium batteries, small-sized cells/battery packs, large-sized cells/battery packs, etc., can solve problems such as lack of suitable current collectors, processes and current collectors that cannot be directly applied, etc. Achieve the effect of omitting the combined welding process, simple manufacturing, and adapting to high current charging and discharging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

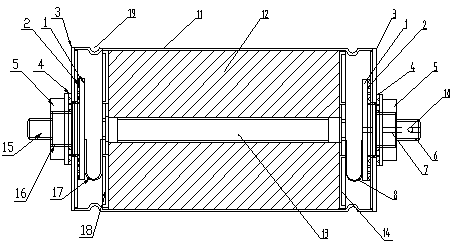

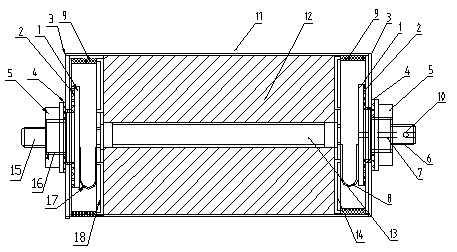

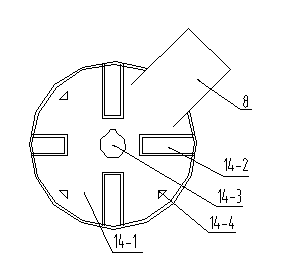

[0021] The end face welded cylindrical lithium battery of the present invention will be further described below with reference to the drawings and specific embodiments.

[0022] Figure 1~Figure 3 Including the end cover conductive plate 1, the insulating pad under the end cover 2, the end cover cover plate 3, the insulating pad on the end cover 4, the nut ring 5, the positive screw 6, the liquid injection hole 7, the positive conductive ear 8, the crimping Sealing ring 9, steel ball 10, shell 11, electric core 12, mandrel 13, positive current collector 14, deflector plate 14-1, groove 14-2, central hole 14-3, liquid guide hole 14-4, Negative electrode screw 15, safety valve hole 16, negative electrode conductive ear 17, negative electrode current collector 18, battery tank 19, etc.

[0023] Such as figure 1 , figure 2 As shown, the present invention is an end-welded cylindrical lithium battery, including a casing 11 and a battery cell 12 wrapped in the casing 11, and a ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com